What is a Stainless Steel Bearing? A Comprehensive Guide to Its Types and Uses

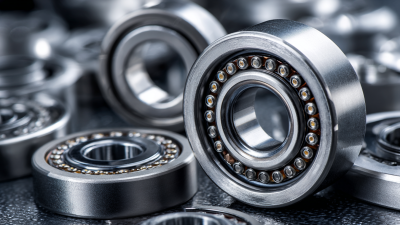

The term "Stainless Steel Bearing" refers to a type of bearing made from stainless steel, a material known for its resistance to corrosion, durability, and strength. This makes stainless steel bearings an ideal choice for a variety of applications, especially in industries where exposure to harsh environments is common. From automotive systems to industrial machinery and even medical devices, stainless steel bearings play a crucial role in ensuring smooth operation and longevity.

In this comprehensive guide, we will delve into the various types of stainless steel bearings available on the market today. We will explore their unique characteristics, advantages, and the specific contexts in which they are most effectively employed. Whether you are an engineer looking for the right component for your project or simply curious about the applications of stainless steel bearings, this guide aims to provide valuable insights and clarity on the subject. Through understanding the different types of stainless steel bearings and their uses, one can make informed decisions based on performance requirements and environmental conditions.

Understanding Stainless Steel Bearings: Definition and Characteristics

Stainless steel bearings are critical components in various industrial applications, renowned for their durability and resistance to corrosion. Defined as rolling element bearings made from stainless steel, these components are designed to withstand extreme environments and maintain performance over time. According to a report by the Research and Markets, the global stainless steel bearings market is projected to grow at a CAGR of 6.5% from 2021 to 2026, reflecting the increasing demand in sectors like automotive, aerospace, and pharmaceuticals.

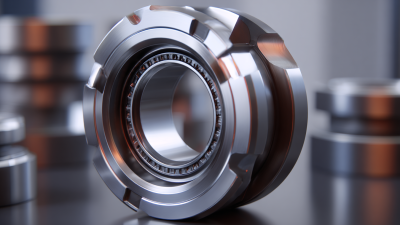

The characteristics of stainless steel bearings include high strength, excellent resistance to oxidation, and an ability to maintain their integrity even in harsh conditions. These bearings typically feature a structure made from austenitic stainless steel, which provides superior toughness and fatigue resistance. Furthermore, the American Society for Testing and Materials (ASTM) highlights that stainless steel bearings can operate effectively at temperatures ranging from -250°C to 300°C, making them an ideal choice for a wide variety of applications including in environments exposed to moisture or chemicals. This versatility enhances their appeal across multiple industries, reinforcing their importance in modern engineering solutions.

Common Types of Stainless Steel Bearings and Their Applications

Stainless steel bearings are vital components in various industries due to their exceptional properties, including resistance to corrosion and high strength. The most common types of stainless steel bearings include deep groove ball bearings, angular contact ball bearings, and cylindrical roller bearings. Each type serves specific applications; for instance, deep groove ball bearings are widely used in electric motors and household appliances, while angular contact bearings are ideal for high-speed and precision machinery. According to a recent industry report, the demand for stainless steel bearings is expected to grow at a CAGR of 6.5% through 2027, reflecting their increasing importance in modern engineering.

When selecting stainless steel bearings, considering the environment is crucial. Tips for optimal performance include ensuring proper lubrication to reduce friction and heat, which contributes to extended bearing life. Additionally, it’s essential to choose the right type of bearing based on load requirements; for heavy loads, cylindrical roller bearings may be more suitable due to their increased load capacity.

Another key application is in the food and beverage industry, where strict hygiene standards necessitate the use of stainless steel bearings that can withstand wash-downs and resist bacterial growth. A recent market analysis highlights that stainless steel bearings in this sector are projected to reach USD 1.5 billion by 2025, indicating their critical role in maintaining equipment performance and safety standards.

Common Types of Stainless Steel Bearings and Their Applications

Advantages of Using Stainless Steel Bearings in Various Industries

Stainless steel bearings are increasingly favored across various industries due to their unique properties that enhance performance and durability. One of the major advantages of using stainless steel bearings is their exceptional resistance to corrosion and oxidation. This characteristic makes them ideal for applications in environments where exposure to moisture, chemicals, or extreme temperatures is common, such as in the food processing, pharmaceutical, and marine industries. By minimizing the risk of rust and wear, stainless steel bearings ensure longer operational life and reduced maintenance costs.

Another significant benefit lies in their superior strength and load-bearing capabilities. Stainless steel bearings can withstand higher loads compared to traditional materials, making them suitable for heavy machinery and high-performance applications. Their ability to maintain precision and reliability under stress translates to improved efficiency and safety in operations. Additionally, the aesthetic appeal of stainless steel, combined with its hygienic properties, positions these bearings as a preferred choice in sectors that require cleanliness and appearance, such as automotive and aerospace.

Overall, the versatility and robustness of stainless steel bearings make them an essential component in modern industrial applications.

Maintenance Tips for Prolonging the Life of Stainless Steel Bearings

Stainless steel bearings are known for their durability and resistance to corrosion, making them ideal for a variety of applications. However, to ensure these benefits are fully realized, proper maintenance is essential. Regular inspection of the bearings is crucial; this includes checking for signs of wear, misalignment, and contamination. If any issues are identified, addressing them promptly can prevent further damage and extend the lifespan of the bearings.

Lubrication is another critical aspect of maintaining stainless steel bearings. Using the right type of lubricant not only reduces friction but also helps protect against moisture and dirt. It’s advisable to follow the manufacturer's recommendations regarding lubrication intervals and type. Additionally, keeping the surrounding environment clean can minimize contamination risks, ensuring optimal performance over time. By adopting these maintenance tips, users can effectively prolong the operational life of stainless steel bearings, enhancing their efficiency and reliability in various applications.

Comparative Analysis: Stainless Steel Bearings vs. Other Bearing Materials

When comparing stainless steel bearings to other bearing materials, it's essential to consider the environment in which they will be used. Stainless steel bearings excel in corrosive and high-temperature settings due to their resistance to rust and oxidation. This makes them an ideal choice for applications in the food, pharmaceutical, and marine industries, where cleanliness and durability are paramount. On the other hand, materials like bronze or plastic bearings may perform better in specific low-load scenarios or where noise reduction is crucial.

Tip: When selecting a bearing material, evaluate the specific operational conditions, including load, speed, and environmental factors. This assessment will help in choosing the most suitable bearing type that ensures optimal performance and longevity.

In addition to corrosion resistance, stainless steel bearings handle a significant amount of mechanical stress while maintaining their form and functionality. Comparatively, other materials might deform or wear out faster under similar conditions. For instance, while ceramic bearings are lightweight and resistant to heat, they lack the toughness of stainless steel. Thus, for applications involving heavy loads and rough handling, stainless steel remains a champion in the bearing field.

Tip: Regular maintenance and lubrication of stainless steel bearings can further enhance their lifespan and performance, making them a practical investment for long-term use.

Related Posts

-

How to Choose the Right Stainless Steel Bearing for Your Application

-

How to Choose the Right Roller Bearing for Optimal Performance and Longevity in Your Machinery

-

Exploring Split Pillow Block Bearings at the 138th Canton Fair 2025: Industry Insights and Trends

-

10 Essential Tips for Choosing Small Pillow Block Bearings for Your Projects

-

How to Choose the Right Cast Steel Block Bearing for Your Industrial Needs

-

Exploring Innovations in Pillow Block Bearing Pullers at the 138th China Import and Export Fair 2025