Unlocking the Benefits of Self Aligning Pillow Block Bearings in Modern Machinery

In the ever-evolving landscape of modern machinery, the quest for efficiency and reliability has led engineers to explore innovative components, such as the Self Aligning Pillow Block Bearing. According to a recent report by MarketsandMarkets, the global market for bearings is projected to reach $80.8 billion by 2025, with self-aligning bearings accounting for a significant share due to their unique ability to compensate for shaft misalignment and reduce wear and tear. This remarkable feature not only enhances the lifespan of machinery but also minimizes operational downtime, leading to increased productivity. With industries striving for optimization, mastering the implementation and benefits of Self Aligning Pillow Block Bearings becomes imperative. By understanding their advantages, including easier installation and superior performance in adverse conditions, businesses can unlock the full potential of their machinery, ensuring a competitive edge in a rapidly advancing market.

Understanding Self Aligning Pillow Block Bearings: A Comprehensive Overview

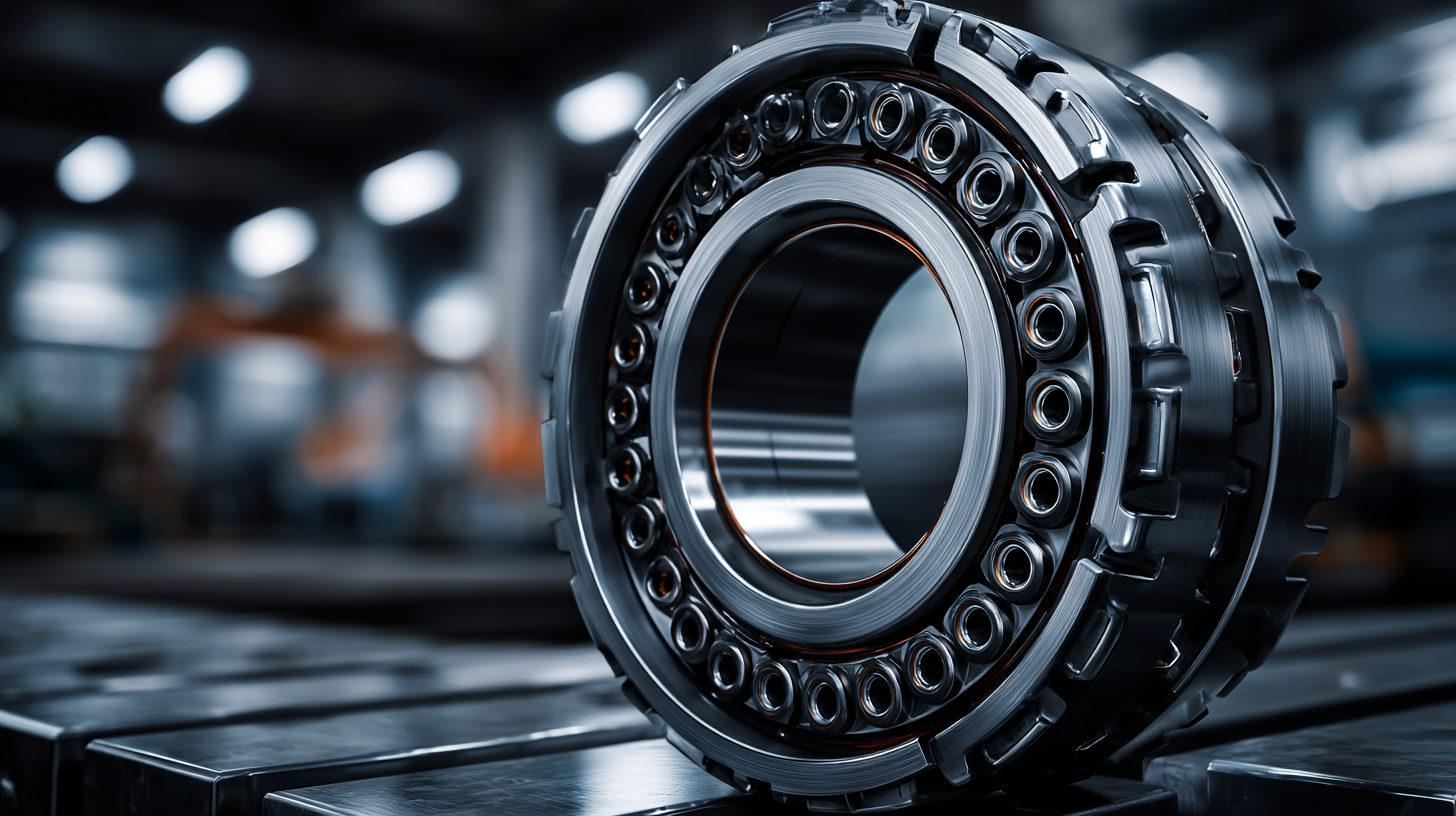

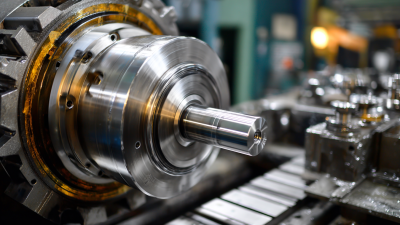

Self-aligning pillow block bearings are crucial components in modern machinery, known for their ability to accommodate misalignment between the shaft and housing. This unique feature stems from their design, which includes two rows of balls and a spherical outer surface, allowing the bearing to pivot freely within the housing. As machinery operates, vibrations and shifts can occur, and these bearings ensure smooth performance while minimizing wear and potential damage.

When implementing self-aligning pillow block bearings, consider these tips:

- First, ensure that the mounting surfaces are properly aligned to maximize the benefits of self-alignment.

- Next, regularly inspect and maintain the bearing housing to prevent contamination and prolong the bearing's lifespan.

- Lastly, choose the right size and load capacity based on your specific application to prevent premature failure and enhance efficiency.

With their versatile application in various industries, understanding the functionality and advantages of self-aligning pillow block bearings can lead to improved operational reliability and reduced downtime. Integrating these bearings into your machinery not only enhances performance but also supports longevity in equipment usage.

Key Advantages of Self Aligning Pillow Block Bearings in Machinery

Self-aligning pillow block bearings are increasingly valuable in modern machinery due to their unique ability to accommodate misalignment and variations in mounting conditions. According to a report by Grand View Research, the global bearing market is expected to reach $130 billion by 2025, driven in part by rising demand for durable and efficient components like self-aligning pillow blocks. These bearings feature a spherical outer surface that allows for angular misalignment, making them ideal for applications involving heavy loads and dynamic movements.

One key advantage is their reduction in maintenance costs. The inherent design of self-aligning pillow block bearings minimizes wear and tear, ensuring longer operating life. A study conducted by the American Society of Mechanical Engineers (ASME) highlights that machinery equipped with self-aligning bearings requires 30% less maintenance than traditional bearings, contributing to lower downtime and increased productivity.

Tips: When selecting self-aligning pillow block bearings for your machinery, consider the load capacity and environmental factors such as temperature and humidity. Regular inspections can also help identify potential issues early, further enhancing the lifespan of these bearings. Additionally, ensure proper installation to leverage their self-aligning capabilities fully, which will optimize performance and reliability.

Unlocking the Benefits of Self Aligning Pillow Block Bearings in Modern Machinery

This bar chart illustrates the key advantages of self-aligning pillow block bearings in various machinery applications, highlighting factors such as durability, maintenance frequency, load capacity, and alignment flexibility.

Applications of Self Aligning Pillow Block Bearings in Various Industries

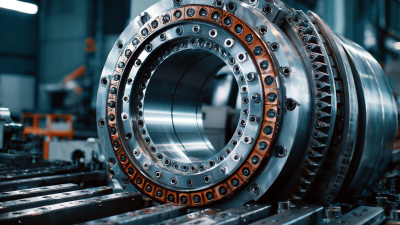

Self aligning pillow block bearings have become essential components in various industries due to their unparalleled ability to accommodate misalignment and reduce maintenance costs. These bearings are widely used in manufacturing, agriculture, and food processing. In manufacturing, they are ideal for conveyor systems and machinery where shaft misalignment is common, helping to enhance operational efficiency and reduce downtime. In agricultural equipment, such as tractors and harvesters, these bearings ensure smooth performance despite harsh working conditions.

Tips: When selecting self aligning pillow block bearings for your application, consider the load capacity and environmental conditions. Make sure to check the bearing's specifications to ensure they can withstand both axial and radial loads effectively.

In the food processing industry, self aligning pillow block bearings are vital for equipment like mixers and conveyors that require easy cleaning and hygiene standards. Their design allows for easy installation and replacement, which is crucial in environments where downtime can lead to lost production. By implementing these bearings, companies can maintain reliable operations and comply with industry standards while enhancing the lifespan of their machinery.

Tips: Regularly inspect and maintain your self aligning pillow block bearings to prevent premature wear. Implementing a routine maintenance schedule can significantly extend the life of your equipment.

Maintenance Tips to Optimize Performance of Self Aligning Pillow Block Bearings

Self-aligning pillow block bearings are essential components in modern machinery, providing enhanced stability and performance. To optimize their functionality, regular maintenance is crucial. Evidence from a report by the National Lubricating Grease Institute indicates that properly lubricated bearings can extend their lifespan by up to 50%. Ensuring that lubrication schedules are adhered to not only minimizes wear but also helps prevent overheating, which is often cited as a leading cause of bearing failure.

Self-aligning pillow block bearings are essential components in modern machinery, providing enhanced stability and performance. To optimize their functionality, regular maintenance is crucial. Evidence from a report by the National Lubricating Grease Institute indicates that properly lubricated bearings can extend their lifespan by up to 50%. Ensuring that lubrication schedules are adhered to not only minimizes wear but also helps prevent overheating, which is often cited as a leading cause of bearing failure.

In addition to lubrication, routine inspection is vital for early detection of potential issues. According to the American Bearing Manufacturers Association, approximately 70% of bearing failures are attributed to contamination and misalignment. Implementing a rigorous inspection regimen will help in identifying signs of wear or misalignment, allowing for corrective measures before catastrophic failure occurs. By prioritizing these maintenance practices, operators can ensure their self-aligning pillow block bearings perform optimally, ultimately leading to increased machinery efficiency and reduced downtime.

Innovations and Future Trends in Self Aligning Pillow Block Bearing Technology

The landscape of self-aligning pillow block bearing technology is continually evolving, driven by advancements in materials and design that enhance their performance in modern machinery. According to a recent report by Research and Markets, the global self-aligning bearing market is projected to grow at a CAGR of 5.2% from 2023 to 2030, indicating a strong demand for efficient and reliable components in various industries, including automotive, aerospace, and manufacturing. Innovations such as improved sealing technologies and the introduction of hybrid bearing materials are significantly reducing friction and increasing the life span of these bearings, catering to the high operational demands of contemporary machinery.

Furthermore, the trend towards automation and the Internet of Things (IoT) is shaping the future of self-aligning pillow block bearings. Integrated smart sensors within bearings enable real-time monitoring of performance metrics, allowing for predictive maintenance and minimizing unexpected downtime. A study by Technavio forecasts that the rise of smart bearings will account for approximately 40% of the market by 2025, as companies seek to enhance efficiency and reduce operational costs. This digital transformation not only optimizes machinery performance but also paves the way for the development of more advanced bearing technologies that align with the sustainable practices favored by today's industries.

Related Posts

-

How to Choose the Right Roller Bearing for Optimal Performance and Longevity in Your Machinery

-

Exploring Innovations in Bearing Factory Production: The Future of Machinery Efficiency

-

Exploring Split Pillow Block Bearings at the 138th Canton Fair 2025: Industry Insights and Trends

-

What You Need to Know About 25mm Pillow Block Bearing

-

Exploring Innovations in Pillow Block Bearing Pullers at the 138th China Import and Export Fair 2025

-

Exploring the Science Behind Bearing Manufacturing: Innovations in Bearing Factory Processes