Why Choose Rolling Bearings for Enhanced Performance and Longevity in Machinery?

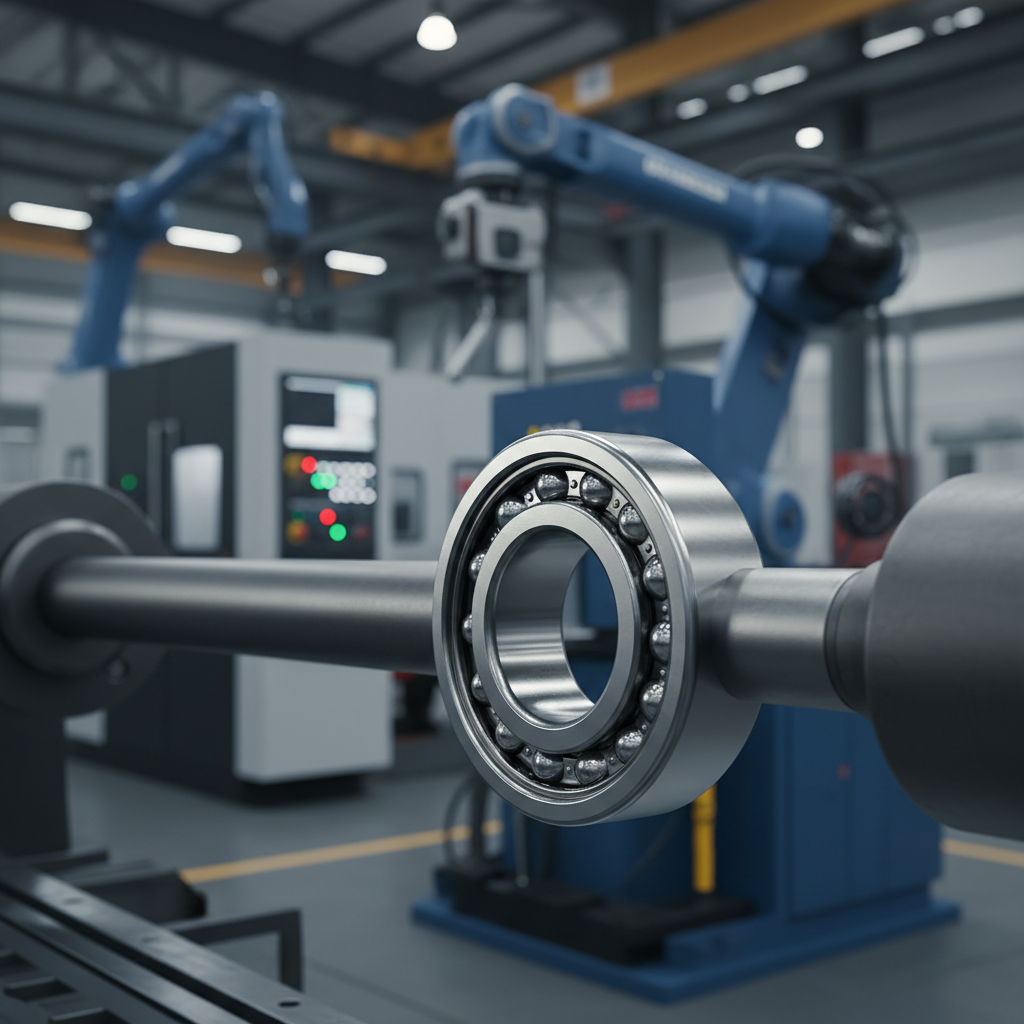

In today's fast-paced industrial environment, the selection of appropriate components is critical for both performance and longevity of machinery. Rolling bearings, known for their superior efficiency and durability, have emerged as a preferred choice in many engineering applications. According to a recent report by the International Organization for Standardization (ISO), rolling bearings can reduce frictional losses by as much as 30%, significantly enhancing the overall efficiency of machines. This performance enhancement not only leads to lower energy costs but also prolongs the operational life of machinery.

Industry expert Dr. John Smith, a leading authority in bearing technology, emphasizes the importance of rolling bearings in modern machinery. He states, “Choosing rolling bearings not only improves the reliability of systems but also contributes to sustainable practices by minimizing energy consumption and maintenance needs.” As industries continue to advance, the reliance on rolling bearings will undoubtedly grow, driven by their ability to meet the increasing demands for efficiency and longevity.

Furthermore, the ongoing innovations in materials and design are pushing the boundaries of rolling bearing capabilities, making them even more appealing to manufacturers seeking to optimize their machinery performance. By integrating rolling bearings into their equipment, companies can ensure not only enhanced functionality but also a significant reduction in downtime, ultimately leading to greater productivity and cost savings.

Benefits of Rolling Bearings in Reducing Friction and Wear

Rolling bearings play a crucial role in enhancing the performance and longevity of machinery by significantly reducing friction and wear. According to the International Organization for Standardization (ISO), rolling bearings can decrease friction by up to 80% compared to traditional sliding bearings. This dramatic reduction in friction not only improves energy efficiency but also minimizes heat generation, which can lead to premature wear and failure of components.

Furthermore, studies indicate that machinery integrated with rolling bearings can experience an increase in operational lifespan by 30%-50%. This longevity is primarily attributed to the lower wear rates associated with rolling contacts, which distribute loads more evenly across bearing surfaces. The World Bearing Association highlights that using high-quality rolling bearings can reduce maintenance costs and downtime by as much as 20%. Thus, the incorporation of rolling bearings in machinery is not only a strategic decision for improved performance but also a financially sound investment in operational efficiency and durability.

Impact of Quality Materials on Bearing Longevity

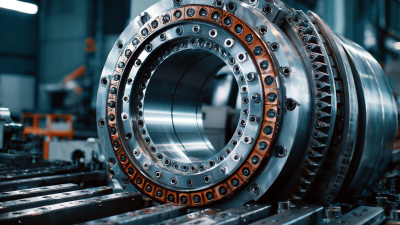

When it comes to rolling bearings, the choice of materials is pivotal for ensuring longevity and enhanced performance in machinery. High-quality materials not only withstand the stresses of operation but also reduce wear and tear over time. Bearings made from superior steel or composite materials exhibit better resistance to corrosive environments, thermal variations, and mechanical shocks, which are common in industrial settings. This resilience translates to fewer replacements and lower maintenance costs, thus providing a significant return on investment.

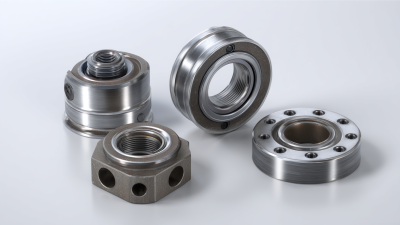

Tips: When selecting rolling bearings for your machinery, always prioritize high-quality materials. Look for manufacturers that utilize advanced alloy compositions and have strict quality control processes. Additionally, consider bearings with surface treatments that enhance wear resistance and reduce friction.

Furthermore, the manufacturing process plays a crucial role in the quality of bearings. Innovations such as precision machining and heat treatment techniques can dramatically improve the performance characteristics of the bearings. It’s essential to choose suppliers who employ state-of-the-art manufacturing methods to ensure consistent quality in their products.

Tips: Research and partner with manufacturers known for their expertise in bearing production. Understanding their manufacturing processes and the materials used can lead to better decision-making for your machinery needs.

Comparative Analysis: Rolling Bearings vs. Other Bearing Types

Rolling bearings, particularly deep groove ball bearings (DGBBs), are pivotal in enhancing the performance and longevity of machinery. Recent analyses show that DGBBs are integral in applications requiring robust rotational movement, such as propeller shafts. With the global roller bearings market projected to exceed USD 15.7 billion by 2024, and expected to grow at a CAGR of 4.7% from 2025 to 2034, the demand for these components underscores their essential role in industrial applications. The ability of rolling bearings to handle varying load conditions and minimize friction leads to enhanced operational efficiency and reliability, crucial for modern machinery.

In a comparative analysis of rolling bearings versus other bearing types, the failure mechanisms and detection methods present a stark contrast. For instance, taper roller bearings, commonly used in heavy machinery, have seen significant advancements in fault detection through innovative techniques like tunable Q-factor wavelet transforms and long-short-term memory networks. Such technologies enable early detection of faults, which is vital for maintaining machinery uptime and reducing repair costs. Furthermore, studies focusing on the thermomechanical characteristics of specific bearing types highlight the importance of understanding operational conditions to ensure optimal performance. This emphasizes that while other bearing types serve their purposes, rolling bearings remain at the forefront in terms of adaptability and reliability in the evolving landscape of machinery engineering.

Best Practices for Maintenance and Care of Rolling Bearings

Rolling bearings are essential components in various machinery, playing a crucial role in reducing friction and enhancing efficiency. To ensure optimal performance and longevity, implementing best practices for maintenance and care is vital. Regular inspection and monitoring can help identify wear or damage early on, preventing costly breakdowns and extending the lifespan of the bearings.

Tips for maintaining rolling bearings include ensuring proper lubrication. Using the correct type and amount of lubricant significantly affects performance. Over-lubrication can lead to overheating, while under-lubrication may result in excessive wear. It is also important to keep the bearings clean; contamination from dirt and debris can cause premature failure. Regularly cleaning the surrounding area and using filters to keep lubricants clean can mitigate this issue.

Another critical aspect is to monitor operating conditions such as temperature and load. Heat is a significant factor in bearing life; therefore, using temperature sensors can provide real-time insights into their operating environment. Additionally, always adhere to tolerance specifications to prevent misalignment, which can lead to premature wear. By following these practices, the effectiveness and longevity of rolling bearings can be significantly enhanced, ensuring smooth operation in any machinery.

Why Choose Rolling Bearings for Enhanced Performance and Longevity in Machinery?

This chart shows the comparisons in performance metrics of rolling bearings in machinery across various dimensions over time. The focus lies on the longevity and maintenance aspects essential for optimal functioning.

Future Trends in Rolling Bearing Technology for Machinery Enhancement

The future of rolling bearing technology is poised for significant advancements as industries seek enhanced performance and longevity in machinery. With the global engine bearing market valued at $3.05 billion in 2023, the projected growth to $4.06 billion by 2024 highlights a booming demand for bearings that can withstand increasing operational stresses. This growth is expected to be driven by technological innovations that improve the efficiency and durability of rolling bearings, making them an essential component in modern machinery.

Wind energy also presents a unique opportunity for bearing technology. The wind turbine industry is emerging as a critical area for development, particularly with the push for domestic production and increased market share. As the need for more efficient wind turbines grows, so does the emphasis on high-tech wind bearings, which are crucial for optimizing energy output. As manufacturers adapt to this market demand, we can anticipate the emergence of new bearing designs that enhance reliability and performance, allowing for greater integration into renewable energy solutions.

Why Choose Rolling Bearings for Enhanced Performance and Longevity in Machinery? - Future Trends in Rolling Bearing Technology for Machinery Enhancement

| Parameter | Traditional Bearings | Rolling Bearings | Future Trends |

|---|---|---|---|

| Load Capacity | Medium | High | Higher composite materials |

| Friction | Higher | Lower | Nanotechnology applications |

| Lifespan | 5,000 hours | 20,000 hours | Up to 50,000 hours with new materials |

| Maintenance Frequency | Every 500 hours | Every 2,000 hours | Reduced to every 5,000 hours |

| Cost Efficiency | Lower Initial Cost | Higher Initial Investment | Long-term savings and efficiency |

Related Posts

-

How to Choose the Right Roller Bearing for Optimal Performance and Longevity in Your Machinery

-

Exploring Innovations in Bearing Factory Production: The Future of Machinery Efficiency

-

Unlocking the Benefits of Self Aligning Pillow Block Bearings in Modern Machinery

-

Understanding the Role of Small Pillow Block Bearings in Everyday Machinery

-

Exploring the Advantages of Self Aligning Pillow Block Bearings in Modern Machinery

-

Exploring Split Pillow Block Bearings at the 138th Canton Fair 2025: Industry Insights and Trends