What is a Roller Bearing and How Does It Improve Machine Efficiency

In the modern industrial landscape, efficiency is paramount, and one critical component that plays a significant role in enhancing machine performance is the roller bearing. As per the latest report by the Global Industry Analysts, the global roller bearing market is projected to reach $30 billion by 2026, driven by the demand for advanced machinery and energy-efficient technologies. Roller bearings reduce friction between moving parts, resulting in smoother operation, improved energy efficiency, and extended equipment lifespan.

Experts in the field, such as Dr. Emily Johnson, a renowned mechanical engineer and roller bearing specialist, emphasize the importance of these components: "The implementation of roller bearings in machinery not only elevates operational efficiency but is also essential for reducing overall maintenance costs." This statement is backed by various studies highlighting that machines equipped with high-quality roller bearings can achieve performance improvements of up to 30%.

In this article, we will explore what roller bearings are, their various types, and how they contribute to the efficiency of machines across different industries. Understanding the operational principles and applications of roller bearings is crucial for engineers and manufacturers aiming to optimize performance and reliability in their systems.

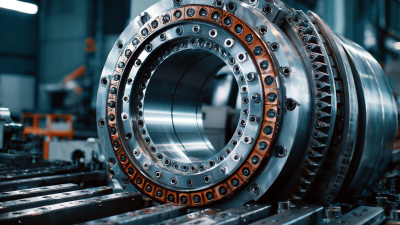

What is a Roller Bearing and Its Role in Machinery

A roller bearing is a crucial component in machinery, designed to reduce friction between moving parts. Unlike traditional ball bearings, roller bearings utilize cylindrical rollers to distribute loads evenly, which enhances their ability to handle heavy radial and axial loads. This unique design allows for smoother movement and increased efficiency in various mechanical applications, from automotive engines to industrial machinery.

The role of roller bearings in machinery cannot be overstated. They not only facilitate smoother rotations but also contribute to the longevity of equipment by minimizing wear and tear. By effectively reducing friction, roller bearings help maintain optimal operating temperatures, preventing overheating and potential failure. This efficiency translates into lower energy consumption, which is advantageous for both operational costs and environmental impact. Thus, incorporating roller bearings into machinery is essential for enhancing performance and reliability in modern engineering applications.

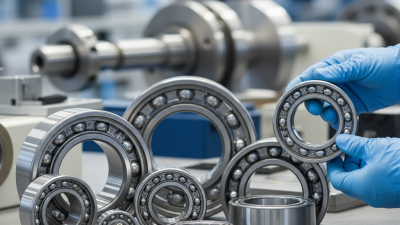

Types of Roller Bearings and Their Application in Industry

Roller bearings are essential components used in various industrial applications, specifically designed to reduce friction and improve the efficiency of machinery. There are several types of roller bearings, including cylindrical, spherical, tapered, and needle roller bearings. Each type is suited for different operational conditions and load configurations. For instance, cylindrical roller bearings excel in handling heavy radial loads, making them ideal for applications in manufacturing and construction equipment. On the other hand, tapered roller bearings are often used in automotive applications due to their ability to support both radial and axial loads.

When selecting the right roller bearing for your application, consider factors such as load capacity, speed, and environmental conditions. Proper lubrication is also crucial; inadequate lubrication can lead to increased wear and reduced efficiency. Tip: Regular maintenance checks can help in identifying wear and tear signs early, ensuring longevity and performance of the bearings.

In high-speed applications, needle roller bearings are preferred due to their compact design and ability to support high loads without occupying much space. Tip: Always reference manufacturer specifications to confirm compatibility with your machinery, as this can significantly impact performance and safety in industrial operations.

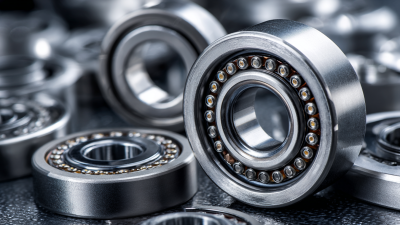

How Roller Bearings Reduce Friction and Enhance Performance

Roller bearings are crucial components in machinery, designed to reduce friction between moving parts. By utilizing cylindrical rollers instead of traditional balls, roller bearings distribute load over a larger surface area, which decreases the contact stress and allows for smoother motion. A report by the American Bearing Manufacturers Association (ABMA) indicates that using roller bearings can reduce friction losses by up to 30% compared to plain sliding bearings. This reduction in friction not only enhances operational efficiency but also contributes to longer service life for bearings and connected components.

Moreover, roller bearings significantly influence the overall performance of machines, particularly in high-speed applications. According to a study published in the Journal of Mechanical Engineering Science, the integration of roller bearings in industrial applications leads to an approximate 15% increase in energy efficiency. This improvement is essential in industries such as automotive and manufacturing, where energy costs represent a substantial portion of operational expenditures. Consequently, the adoption of roller bearings not only improves performance but also supports sustainability efforts by reducing energy consumption and operational costs.

Impact of Roller Bearings on Machine Efficiency

Key Factors for Selecting the Right Roller Bearing for Your Machine

Selecting the right roller bearing is crucial for optimizing machine efficiency. Roller bearings reduce friction between moving parts, allowing for smoother operation and improved overall performance. As industries continue to invest in advanced machinery, the global roller bearing market is projected to reach a value of $468.2 billion in 2024, with an anticipated growth trajectory bringing it to $500.16 billion by 2025 and further expanding to $971 billion by 2032. This significant increase underscores the importance of selecting high-quality bearings that meet specific performance requirements.

When choosing roller bearings, several key factors should be considered, including load capacity, operational speed, and environmental conditions. It’s essential to assess the type of load the bearing will support—whether it's radial or axial—to ensure the selected bearing can handle the expected range of stress. Additionally, understanding the alignment and clearance requirements can significantly enhance machine reliability and longevity. With continuous advancements in bearing technologies, industries must remain informed about the latest innovations to make informed purchasing decisions that align with their operational needs.

Maintenance Tips to Maximize the Efficiency of Roller Bearings

To maximize the efficiency of roller bearings, proper maintenance is crucial. Regular inspection and lubrication are essential practices that can prevent premature wear and tear. Utilizing high-quality bearing lubricants helps reduce friction and heat generation, ultimately enhancing the performance and longevity of the bearings. Additionally, implementing preventative maintenance schedules ensures that any potential issues are identified and resolved before they lead to significant downtime or failure in machinery.

Moreover, innovations in tooling for bearing maintenance can greatly improve safety and efficiency. For instance, specialized tools for the installation and removal of bearings reduce the risks associated with traditional methods, which often involve heavy lifting and manual handling. Ensuring that the equipment is in top operating condition through regular checks, particularly during peak operational times, such as harvest seasons, can significantly boost machine productivity. By adhering to these maintenance tips and utilizing advanced tools, operators can ensure that roller bearings perform optimally and contribute to overall machine efficiency.

Related Posts

-

How to Choose the Right Roller Bearing for Optimal Performance and Longevity in Your Machinery

-

Exploring Innovations in Bearing Factory Production: The Future of Machinery Efficiency

-

Unlocking the Benefits of Self Aligning Pillow Block Bearings in Modern Machinery

-

Why Choose Rolling Bearings for Enhanced Performance and Longevity in Machinery?

-

How to Find the Best Pillow Block Bearings Near Me for Optimal Performance and Durability

-

How to Choose the Right Stainless Steel Bearing for Your Application