Understanding the Role of Small Pillow Block Bearings in Everyday Machinery

Small Pillow Block Bearings play a crucial role in the functionality and longevity of various machinery used in everyday applications. These compact yet powerful components are designed to support rotating shafts and reduce friction, making them essential in numerous industries, including manufacturing, automotive, and consumer goods. According to a recent market report by Research and Markets, the global bearing market is projected to reach $202.7 billion by 2027, driven significantly by the increasing demand for high-performance and reliable bearings like Small Pillow Block Bearings. Their unique design allows for easy installation and effective alignment, optimizing machine performance while minimizing maintenance costs. As industries continue to evolve, understanding the importance and application of Small Pillow Block Bearings is paramount for engineers and technical professionals aiming to enhance operational efficiency and equipment reliability.

Importance of Small Pillow Block Bearings in Mechanical Systems

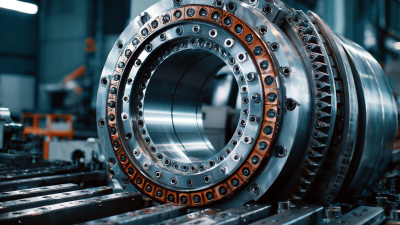

Small pillow block bearings play a crucial role in the functionality of various mechanical systems found in everyday machinery. These bearings serve as supports for rotating shafts, allowing for smooth and efficient motion by minimizing friction. Their compact size makes them ideal for applications where space is limited, while their robustness ensures durability and reliability under varying operational conditions.

In recent studies, researchers have focused on different types of bearings, including angular contact ball bearings, to analyze stresses under static loading. Factors such as race thickness and housing stiffness significantly influence the performance and lifespan of these components. Understanding these parameters aids in optimizing the design and application of small pillow block bearings, ensuring they can effectively support heavier loads and operate seamlessly within mechanical systems. The integration of advanced modeling techniques further enhances our comprehension of how these bearings contribute to the stability and efficiency of machinery.

Key Features and Benefits of Small Pillow Block Bearings

Small pillow block bearings play a pivotal role in the functionality of everyday machinery, providing critical support to rotating shafts in various applications. According to a recent report by the International Journal of Engineering Research & Technology, these bearings can significantly reduce friction and enhance operational efficiency, leading to increased lifespan and performance of machinery. The design of small pillow block bearings allows for easy installation and replacement, which is a major advantage in maintenance schedules, especially in industrial settings where downtime can be costly.

One of the key features of small pillow block bearings is their versatility, which enables them to be utilized in a wide range of equipment—from conveyor systems to agricultural machinery. The American Bearing Manufacturers Association (ABMA) indicates that these bearings can handle both radial and axial loads, making them suitable for demanding applications. Additionally, their compact design allows for space-saving installations without compromising on strength. The increase in demand for efficient and reliable machinery is driving the growth of the pillow block bearings market, which is projected to reach $15 billion by 2025, reflecting their crucial role in the advancement of manufacturing technologies.

Understanding the Role of Small Pillow Block Bearings in Everyday Machinery

Common Applications of Small Pillow Block Bearings in Everyday Machinery

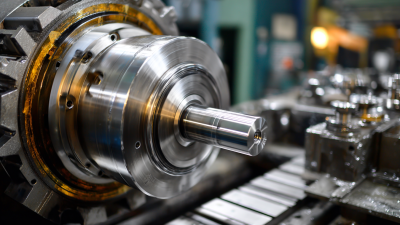

Small pillow block bearings play a crucial role in the functionality of various everyday machinery. These compact devices are designed to support rotating shafts while ensuring smooth movement and reducing friction. Their design allows them to fit into confined spaces, making them ideal for use in equipment such as electric motors, conveyor systems, and even lawn maintenance tools. The versatility and reliability of small pillow block bearings contribute significantly to enhanced operational efficiency across multiple sectors.

In addition to their widespread use in industrial applications, small pillow block bearings are also found in household appliances, such as washing machines and fans. They facilitate smooth rotation in mechanical components, which is essential for the optimal performance of these devices. Furthermore, their ability to withstand heavy loads while operating at high speeds makes them integral to the durability and longevity of machines we encounter daily. Thus, understanding their applications not only highlights their importance in machinery but also emphasizes the need for proper maintenance to ensure continuous service and avoid costly downtime.

Maintenance Tips for Enhancing the Longevity of Pillow Block Bearings

Pillow block bearings play a crucial role in the functionality of everyday machinery, providing support and stability to rotating shafts. However, like all mechanical components, they require regular maintenance to ensure their longevity and optimal performance. By implementing a few simple and effective tips, users can enhance the lifespan of their pillow block bearings significantly.

One key maintenance tip is to ensure regular lubrication. This helps reduce friction and wear between moving parts. Use the recommended lubricant and apply it as directed by the manufacturer to avoid contamination and excess buildup. Additionally, keeping the bearings clean from dust and debris is essential. Regularly inspect the bearings for any signs of dirt accumulation or damage, and clean them with appropriate solvents when necessary.

Another important aspect is ensuring proper alignment. Misalignment can lead to premature wear and potential failure of the bearings. It’s vital to regularly check the alignment of the shafts and adjust as needed to prevent undue stress. Lastly, monitoring the operating temperature of the bearings can help identify any potential issues before they escalate. If the bearings run hotter than normal, it may indicate insufficient lubrication or a need for reevaluation of the system's setup. Implementing these maintenance tips will not only extend the life of pillow block bearings but also improve overall machinery efficiency.

Future Trends and Innovations in Pillow Block Bearing Technology

As industries continue to advance, the importance of pillow block bearings remains vital in the machinery sector. The future of pillow block bearing technology is poised for innovation, focusing on enhancing efficiency and reliability. Recent developments aim at integrating smart technologies, such as sensors, into these bearings to predict failures before they happen, significantly reducing downtime and maintenance costs. Manufacturers are also exploring new materials that provide better durability and lower friction, which further enhances performance.

**Tips:** When selecting pillow block bearings for your machinery, consider the load capacity and environmental factors, such as temperature and humidity, that could affect performance. Regular maintenance checks can help extend the lifespan of these components, so establishing a routine schedule is essential.

Another exciting trend is the shift towards sustainable practices in bearing manufacturing. Companies are now prioritizing recycled materials and environmentally friendly processes, aligning with global sustainability goals. Adopting these innovations not only benefits the environment but also appeals to a growing market that values eco-friendly products.

**Tips:** Stay updated on technology trends in pillow block bearings to ensure you leverage the latest advancements. Engaging with suppliers who prioritize sustainability can also enhance your company's reputation and marketability.

Understanding the Role of Small Pillow Block Bearings in Everyday Machinery

| Dimension (mm) | Load Capacity (kg) | Material | Applications | Future Trends |

|---|---|---|---|---|

| 20 x 25 | 150 | Steel | Conveyor Systems | Smart Sensors |

| 30 x 40 | 300 | Aluminum | Agricultural Equipment | 3D Printing Innovations |

| 25 x 30 | 200 | Plastic | Home Appliances | Eco-friendly Materials |

| 20 x 30 | 175 | Stainless Steel | Robotics | Enhanced Durability |

| 35 x 50 | 400 | Composite | Industrial Machinery | Automation Integration |

Related Posts

-

How to Choose the Right Roller Bearing for Optimal Performance and Longevity in Your Machinery

-

Exploring Split Pillow Block Bearings at the 138th Canton Fair 2025: Industry Insights and Trends

-

Exploring Innovations in Bearing Factory Production: The Future of Machinery Efficiency

-

Exploring Innovations in Bearing Factory Automation: A Guide for Modern Manufacturing

-

Exploring the Science Behind Bearing Manufacturing: Innovations in Bearing Factory Processes

-

Exploring Innovations in Pillow Block Bearing Pullers at the 138th China Import and Export Fair 2025