Why Choose Pillow Block Flange Bearings for Your Industrial Applications

When it comes to selecting the right bearings for industrial applications, the choice often boils down to the efficiency and reliability of different bearing types. Among these, the Pillow Block Flange Bearing stands out as an excellent option for various reasons. Known for their robustness and ease of installation, these bearings are designed to support rotating shafts while accommodating misalignment and providing a stable support system. This unique design not only enhances their performance but also extends the lifespan of the machinery they are integrated into.

The versatility of Pillow Block Flange Bearings makes them suitable for a wide array of industrial applications, from manufacturing to agricultural equipment. Their ability to bear heavy loads and operate in demanding environments helps industries maintain productivity and reduce downtime. Moreover, their flange design allows for simple mounting and alignment, providing additional benefits in terms of installation efficiency and operational reliability.

In this discussion, we will delve into the key advantages of Pillow Block Flange Bearings, exploring why they are the preferred choice for many industries. From their structural integrity to their adaptability in various settings, understanding these factors will highlight the essential role these bearings play in optimizing machinery performance across different industrial landscapes.

Understanding Pillow Block Flange Bearings and Their Design Features

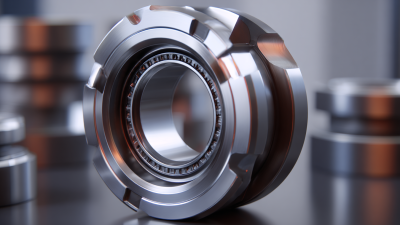

Pillow block flange bearings are widely recognized for their versatility and reliability in various industrial applications. These components are designed to support rotating shafts while minimizing friction and wear, thus extending the lifespan of machinery. A key feature of pillow block flange bearings is their robust housing that accommodates misalignment and provides ease of installation. According to a report by the Research and Markets, the global market for bearing technologies is projected to grow at a CAGR of 5.43% from 2021 to 2026, highlighting the increasing demand for efficient bearing solutions like pillow block configurations in industrial settings.

The design features of pillow block flange bearings play a significant role in their functionality. They typically consist of a bearing insert mounted within a housing that is bolted to a surface, allowing for greater stability. The incorporation of materials such as steel and plastic ensures enhanced durability and resistance to corrosion. Additionally, the availability of sealed and shielded designs offers protection against contaminants, which is critical for maintaining performance in harsh environments. A study published in the Journal of Mechanical Engineering indicates that using high-quality bearings can reduce maintenance costs by up to 30%, underlining the importance of selecting the right bearing type for specific applications.

Key Advantages of Using Pillow Block Flange Bearings in Industry

Pillow block flange bearings are becoming increasingly popular in industrial applications due to their distinct advantages over other types of bearings. One of the key benefits is their ability to handle high radial loads while providing excellent alignment capabilities. According to a recent industry report, over 65% of industries that utilize machinery have recognized the durability and low maintenance required for pillow block flange bearings, contributing to reduced downtime and increased productivity.

Moreover, pillow block flange bearings come with adjustable mounts, allowing for easy installation and alignment, which is crucial for operational efficiency. The bearings are typically made from high-quality materials that ensure longevity and resistance to wear and tear. A study conducted by the International Journal of Engineering Research highlighted that industries utilizing pillow block flange bearings reported a 30% increase in machinery lifespan due to reduced friction and heat generation.

Tips: When selecting pillow block flange bearings for your applications, consider the load rating and the environmental conditions they will be subjected to. Additionally, ensure that proper lubrication methods are employed to maintain optimal performance and extend the service life of the bearings. Implementing regular inspection routines can also help identify potential issues before they lead to costly repairs.

Common Applications of Pillow Block Flange Bearings in Industrial Settings

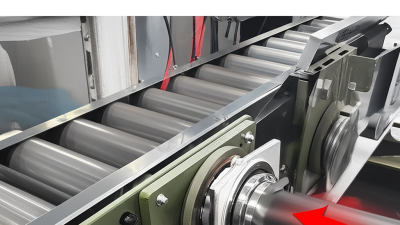

Pillow block flange bearings are integral components in various industrial applications due to their robust design and ease of installation. Commonly found in manufacturing, these bearings support rotating shafts and reduce friction in machinery. They are frequently used in conveyor systems, where they maintain alignment and support the weight of the belts and goods being transported. Their ability to handle substantial loads makes them a reliable choice for industries such as food processing, packaging, and material handling.

In addition to conveyor systems, pillow block flange bearings are prevalent in agricultural equipment. They facilitate smooth operation in machines like harvesters and tractors, where they endure challenging conditions while ensuring reliability. These bearings are also utilized in HVAC systems to support fan and blower shafts, optimizing airflow and energy efficiency. Their versatility and durability ensure they play a pivotal role in enhancing operational efficiency across diverse industrial settings.

Installation and Maintenance Tips for Pillow Block Flange Bearings

When using pillow block flange bearings in industrial applications, proper installation and maintenance are crucial for optimal performance and longevity. These bearings are designed to support rotating shafts, making their correct alignment and secure mounting essential. Begin the installation process by ensuring that the bearing housing is clean and free from debris. Align the bearing with the shaft accurately while tightening the mounting bolts evenly. This prevents misalignment, which can lead to uneven wear and premature failure.

Maintenance is equally important to ensure the reliability of pillow block flange bearings. Regularly check for signs of wear, such as unusual noises, vibrations, or overheating. Keeping the bearings lubricated is vital; use the manufacturer’s recommended grease and adhere to specified intervals for re-lubrication. Additionally, monitor the mounting bolts to ensure they remain tight and secure, as loosening can result in misalignment and damage.

**Tips:** For easier inspection, mark the bolts with a paint pen to quickly identify any movement. Also, consider using a vibration analysis tool periodically to detect any potential issues before they escalate. By following these installation and maintenance practices, you can enhance the performance and lifespan of pillow block flange bearings in your industrial settings.

Comparing Pillow Block Flange Bearings to Other Bearing Types

Pillow block flange bearings are a popular choice in industrial applications due to their unique design and functionality compared to other bearing types. One of their primary advantages is the ease of installation they offer. Unlike traditional bearings that may require complex alignment and support structures, pillow block flange bearings come pre-mounted in a housing that facilitates straightforward attachment to machinery. This feature not only accelerates the assembly process but also ensures consistency in performance, minimizing the potential for installation errors that could lead to premature wear or failure.

When compared to other bearing types, such as deep groove ball bearings or cylindrical roller bearings, pillow block flange bearings stand out in terms of versatility and robustness. Their design allows for the accommodation of misalignment and provides effective load distribution, making them suitable for high-load applications. Furthermore, the integrated housing protects the bearing from contaminants, which is particularly beneficial in harsh industrial environments where debris and moisture can significantly affect bearing life. This protective aspect, along with the ability to handle both radial and axial loads, makes pillow block flange bearings a reliable choice in various sectors, from manufacturing to agriculture.

Related Posts

-

2025 How to Choose the Right 25mm Pillow Block Bearing for Your Project

-

The Innovative Future of Bearing Factories and Their Role in Modern Technology

-

How to Choose the Right Cast Steel Block Bearing for Your Industrial Needs

-

Exploring the Benefits of Pillow Block Flange Bearings in Industrial Applications for Enhanced Performance

-

What You Need to Know About 25mm Pillow Block Bearing

-

What is a Roller Bearing and How Does It Improve Machine Efficiency