Understanding Pillow Block Bearings: Types and Where to Find Them Near Me

In the realm of mechanical engineering and maintenance, pillow block bearings play a critical role in ensuring the efficient operation of machinery and equipment. By supporting rotating shafts and facilitating smooth movement, these bearings are indispensable in various industrial applications. As the demand for reliable components grows, understanding the types and specifications of pillow block bearings becomes essential for industry professionals and DIY enthusiasts alike. According to John Smith, a leading expert in the field of bearing technology, “Finding reliable suppliers for pillow block bearings near me is crucial for maintaining operational efficiency.”

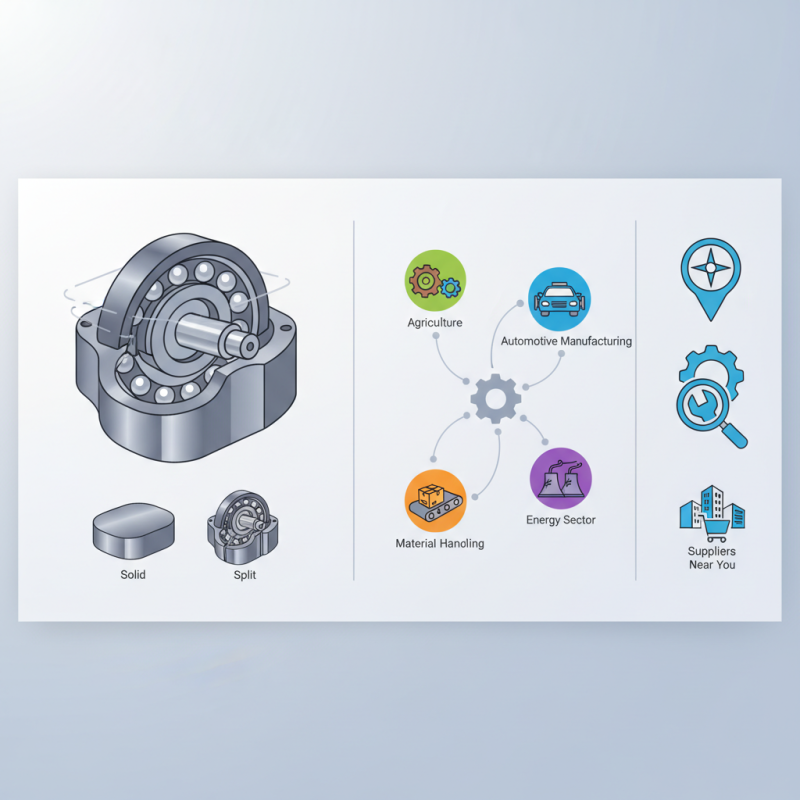

The quest for effective pillow block bearings near me not only involves recognizing the different types available, such as solid or split pillow block designs, but also understanding their applications in diverse sectors. From agriculture to automotive manufacturing, the need for quality bearings cannot be overstated. This article aims to provide insight into the various types of pillow block bearings and explore where to locate them in your vicinity, ensuring that you can make informed decisions for your specific needs. With the right information at hand, sourcing the best pillow block bearings will become a simpler and more effective task.

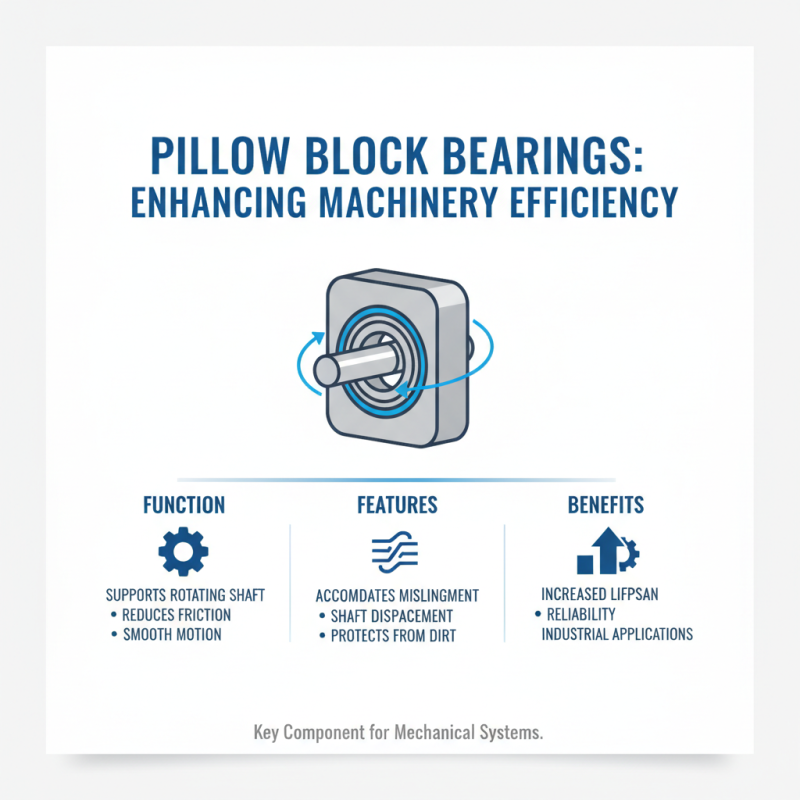

Understanding the Basics of Pillow Block Bearings and Their Functions

Pillow block bearings are essential components widely used in various mechanical applications. They consist of a mounted bearing unit that supports a rotating shaft, allowing for smooth motion and reducing friction. Understanding the basic functions of pillow block bearings can help users appreciate their role in enhancing machinery efficiency. These bearings are designed to accommodate misalignment and shaft displacement, which makes them ideal for industrial settings where precise alignment may not be feasible. The pillow block housing protects the bearing from dirt and debris, further extending its lifespan.

The versatility of pillow block bearings enables their use in numerous applications, from conveyor systems to agricultural machinery. They can support radial loads and axial loads, depending on the specific design. When selecting a pillow block bearing, it is crucial to consider factors such as load capacity, material, and mounting type to ensure optimal performance. For those looking to find pillow block bearings locally, various industrial supply stores and machinery suppliers typically carry a range of options to meet diverse needs. Understanding their basic functions and features allows users to make informed choices for their specific applications.

Types of Pillow Block Bearings: A Comprehensive Overview

Pillow block bearings are integral components in various mechanical applications, providing support and facilitating smooth rotational movement. These bearings come in several types, each designed to accommodate specific needs. The most common types include the cast iron pillow block, which is renowned for its strength and durability, and the thermoplastic pillow block, which offers resistance to corrosion and chemical exposure. According to the Global Pillow Block Bearings Market Report, the demand for these components is projected to grow at a CAGR of 6.2% through 2025, driven by increasing automation in manufacturing and rising investments in infrastructure.

In addition to cast iron and thermoplastic materials, there are also stainless steel pillow block bearings, which excel in environments where hygiene is essential, such as in food processing or medical equipment. Furthermore, flange-mounted pillow block bearings are designed to be easily integrated into new or existing structures, providing versatility in installation. Data from industry analyses indicate that the expansion of industries such as automotive and aerospace is significantly boosting the need for reliable and innovative bearing solutions, making understanding these various types crucial for engineers and procurement specialists alike.

Understanding Pillow Block Bearings: Types and Where to Find Them Near Me

| Type of Pillow Block Bearing | Material | Load Capacity (lbs) | Temperature Range (°F) | Common Applications | Where to Find |

|---|---|---|---|---|---|

| Standard Pillow Block | Cast Iron | 1500 | -20 to 200 | Agricultural Machinery | Local Hardware Store |

| Heavy-Duty Pillow Block | Steel | 2500 | -40 to 250 | Mining Equipment | Industrial Supply Warehouse |

| Self-Aligning Pillow Block | Plastic | 1200 | 0 to 180 | Food Processing | Online Retailers |

| Stainless Steel Pillow Block | Stainless Steel | 2000 | -10 to 300 | Marine Applications | Local Marine Supply Shops |

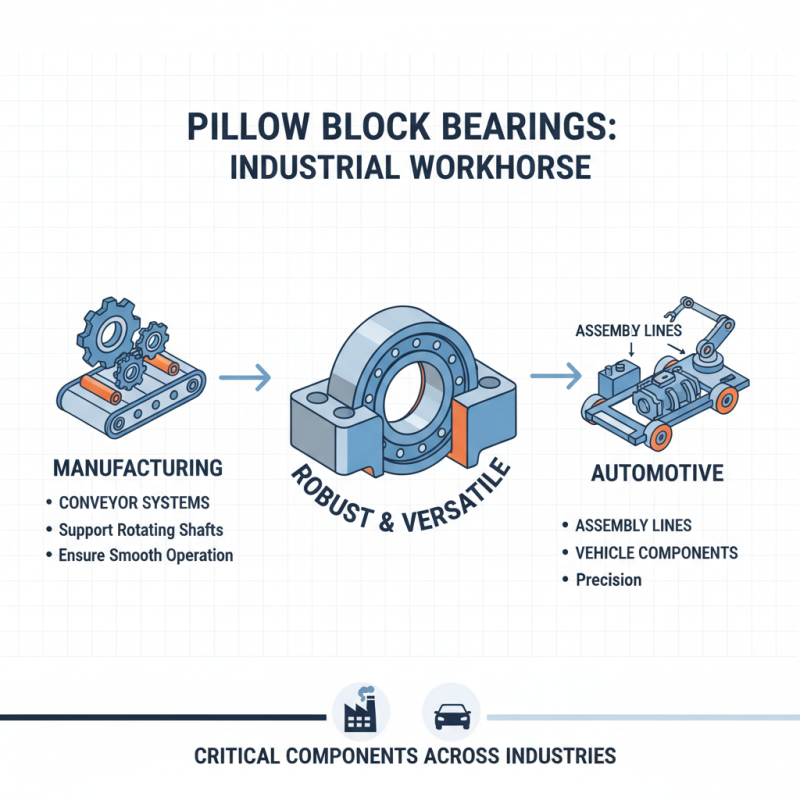

Key Applications and Industries Utilizing Pillow Block Bearings

Pillow block bearings are critical components utilized across various industries due to their robustness and versatility. In manufacturing, these bearings are often found in conveyor systems, where they support rotating shafts and ensure smooth operation. The automotive industry also relies heavily on pillow block bearings for various applications, including in assembly lines and vehicle components, where durability and precision are paramount.

Additionally, pillow block bearings play a crucial role in agricultural machinery, helping to ensure efficient operation of equipment like tractors and harvesters. By providing stability and reducing friction in moving parts, these bearings contribute significantly to the overall productivity of agricultural operations. The adaptability of pillow block bearings makes them essential in both heavy-duty applications and lighter machinery, highlighting their importance across different fields.

How to Select the Right Pillow Block Bearing for Your Needs

When selecting the right pillow block bearing for your needs, it's crucial to understand the various factors that contribute to optimal performance in your specific application. Pillow block bearings are designed to support shafting and are typically mounted on a surface. One key consideration is the load capacity; according to a report by the American Bearing Manufacturers Association (ABMA), it is essential to match the bearing's load rating with the anticipated dynamic and static loads in your operation. Overestimating or underestimating these needs can lead to premature bearing failure or, conversely, unnecessary expenditures on oversized components.

Additionally, the choice of material can significantly impact the service life of the bearing. For instance, bearings made from stainless steel or composite materials are often preferred for corrosive environments, as noted in the Machinery Lubrication Journal. Furthermore, it is important to consider environmental factors such as temperature range and potential exposure to dust or moisture. Utilizing resources like the International Organization for Standardization (ISO) can aid your selection process, ensuring you comply with relevant standards for performance and safety. Understanding these criteria will not only streamline your selection but also enhance the efficiency and reliability of your machinery.

Where to Find Quality Pillow Block Bearings Near You: A Local Guide

When searching for quality pillow block bearings in your local area, a combination of online resources and physical stores can lead you to the best options. Start by checking with local

suppliers and industrial equipment stores, as they often carry a range of bearings suitable for different applications. Moreover, community boards and local business directories can provide listings of nearby suppliers specializing in

mechanical parts. Don't forget to ask if the store can order specific types of bearings if they don't have them in stock.

Tips for identifying quality pillow block bearings include looking for signs of durability such as high-quality materials and a solid construction. Additionally, it's crucial to verify that the supplier provides adequate warranties and return policies. Engaging with local machinery or

automotive workshops can also yield valuable recommendations on where to find reliable bearings, as they often have established relationships with suppliers and can point you toward trusted sources.

Make sure to inquire about the specifications of the bearings you need, including size, load capacity, and any specific environmental considerations. Understanding these requirements will help you narrow down your search and ensure you find the right pillow block bearings for your projects.

Related Posts

-

How to Find the Best Pillow Block Bearings Near Me for Optimal Performance and Durability

-

Top 10 Pillow Block Bearings Near Me for Optimal Performance and Value

-

Unlocking the Benefits of Self Aligning Pillow Block Bearings in Modern Machinery

-

Understanding the Role of Small Pillow Block Bearings in Everyday Machinery

-

2025 Top 5 Harga Pillow Block Bearing: Key Features and Market Insights for Optimal Performance

-

2025 How to Choose the Right Pillow Block Bearings and Shaft for Your Needs