Why Choose Pillow Block Bearings for Your Machinery Needs?

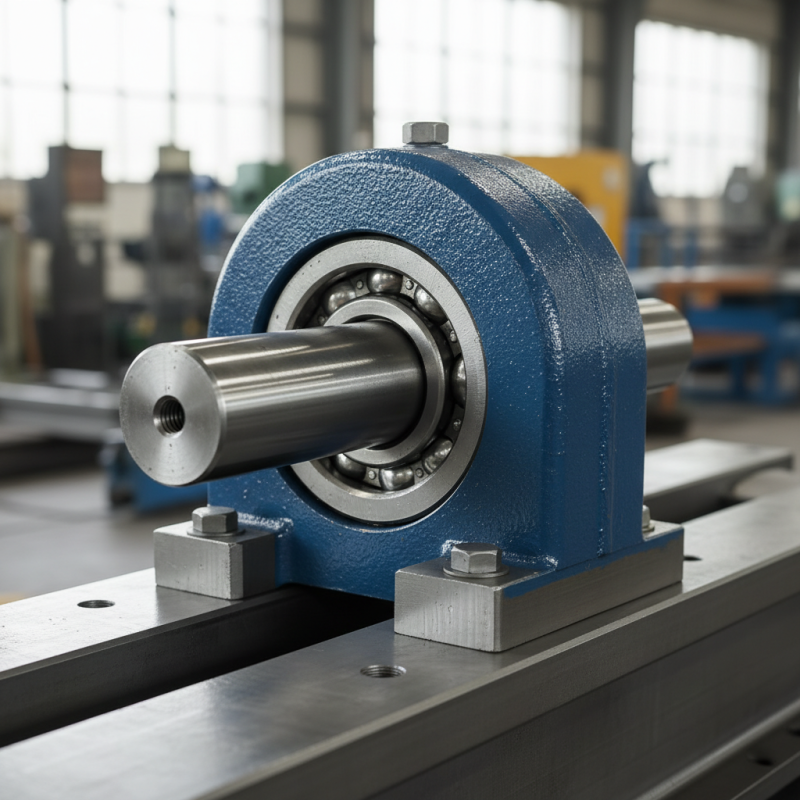

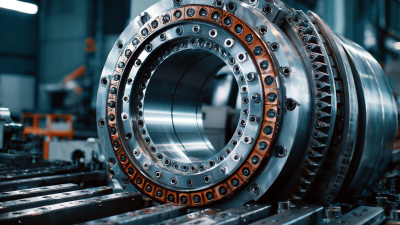

When it comes to machinery, choosing the right components is essential. A Pillow Block Bearing can be a game changer for various applications. These bearings support rotating shafts and help to reduce friction. They are crucial in ensuring smooth operation and reliability in machinery.

What makes Pillow Block Bearings stand out? Their design allows for easier installation and maintenance. This component typically comes pre-assembled, saving time during setup. It is easy to replace when worn out, which can save costs in the long run. However, it’s important to select the appropriate type for your specific needs. Not all Pillow Block Bearings are the same; they vary in material, size, and load capacity.

While many benefits exist, there can be drawbacks. Over time, misalignment can occur, leading to premature wear. Regular maintenance is necessary to avoid potential failures. A Pillow Block Bearing may not be suitable for every application, which is worth considering. Choosing wisely ensures that your machinery operates efficiently and effectively.

Understanding Pillow Block Bearings and Their Functionality

Pillow block bearings play a crucial role in machinery efficiency. They provide support and stability to rotating shafts. In various industrial applications, these bearings manage high loads with ease. A report by the National Lubricating Grease Institute indicates that proper bearing support can extend machinery life by up to 30%. This is significant for companies looking to minimize downtime and maintenance costs.

The functionality of pillow block bearings lies in their design. They typically feature a mounted block that houses the bearing. This design allows for easy installation and replacement. According to a study from the American Society of Mechanical Engineers, nearly 40% of machinery failures are linked to bearing issues. This highlights the importance of choosing the right type of bearing. However, the installation process requires precise alignment. Any misalignment can lead to premature failure.

Pillow block bearings also offer versatility. They can be used in various environments, from dusty settings to high-temperature zones. Yet, they are not a one-size-fits-all solution. Regular inspection and maintenance are necessary to ensure optimal performance. Technical specifications must align with machinery requirements. This can complicate selection for some users, making it a consideration for careful reflection.

Advantages of Using Pillow Block Bearings in Machinery

Pillow block bearings are a popular choice for various machinery applications. They offer several advantages that enhance performance and reliability. One key benefit is their ability to handle misalignment. They can accommodate slight shifts in position, which helps reduce wear and tear on components. This feature can extend the lifespan of your machinery.

Another advantage is their ease of installation. Pillow block bearings come pre-assembled and ready to mount. This saves time and labor costs during setup. Additionally, they are designed to facilitate maintenance. Many designs allow for easy access to lubrication points, promoting efficiency.

**Tips:** When selecting pillow block bearings, consider the environment they'll operate in. Factors like humidity and dust can affect performance. Ensure you choose a bearing that suits your specific conditions. Regularly check for signs of wear; early detection can save money down the line.

Don’t overlook proper alignment. Even though pillow block bearings can manage some misalignment, significant deviations can still cause issues. Regularly inspect alignment to maintain optimal functionality. Understanding these aspects can greatly impact your machinery's efficiency.

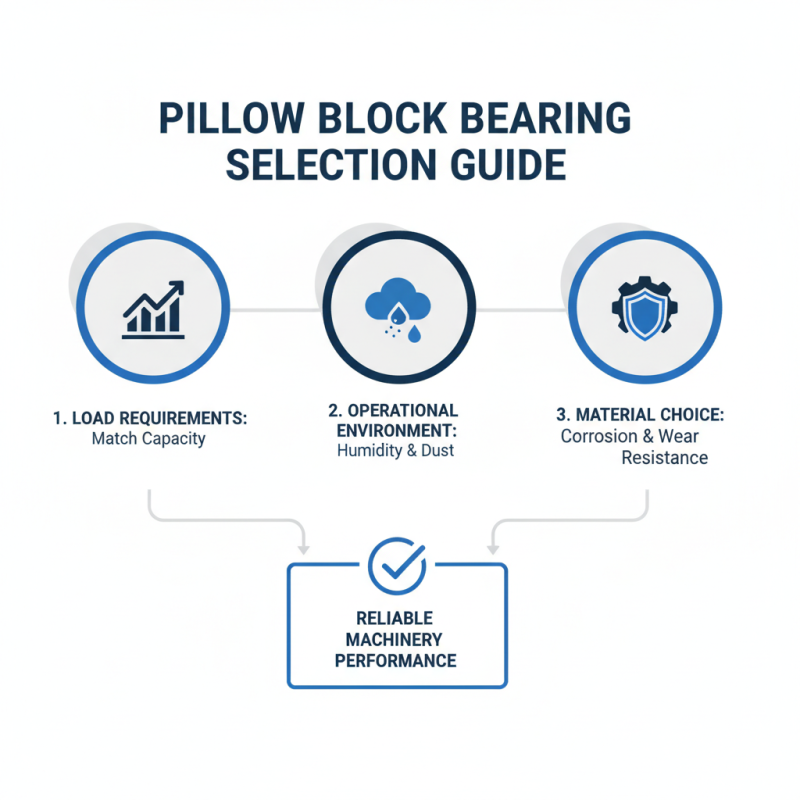

Key Factors to Consider When Selecting Pillow Block Bearings

When selecting pillow block bearings for machinery, several crucial factors come into play. Consider your application’s load requirements. Each bearing has a specific load capacity. If you underestimate this, it could lead to premature failure. Assessing the expected operational environment is essential too. High humidity or dust can influence performance. Choose materials that resist corrosion or wear.

Tips: Always verify the load ratings. They can vary significantly. Overloading bearings can lead to reduced lifespan.

Additionally, pay attention to lubrication needs. Some pillow block bearings require regular maintenance. Others are sealed and need less. Choose according to your maintenance capabilities. Remember, a simple oversight can lead to costly downtime.

Tips: Look for user-friendly options. They can save time and effort during installation and maintenance. Adjusting your selection based on real-world insights can lead to better outcomes. Staying aware of these points enhances efficiency.

Common Applications of Pillow Block Bearings in Industries

Pillow block bearings are essential in various industries due to their unique design and functionality. These bearings can support shafts, while providing alignment and stability. They are widely used in agriculture, construction, and manufacturing sectors. In agriculture, for example, pillow block bearings help keep machinery like tractors and harvesters running smoothly. The ability to withstand harsh conditions makes them a reliable choice.

In manufacturing, these bearings play a vital role in conveyor systems and assembly lines. They keep the machinery functioning efficiently, avoiding downtime. Issues can occur when bearings are not maintained properly. Over time, dirt and debris accumulate, leading to potential failures. It's important for operators to regularly check and replace them when necessary.

Construction equipment also benefits greatly from pillow block bearings. In cranes and hoists, they ensure safe and smooth operation. However, selecting the correct size and type requires careful consideration. Sometimes, the wrong choice can lead to mechanical failures. Being aware of these details is crucial for optimal performance in any application.

Why Choose Pillow Block Bearings for Your Machinery Needs? - Common Applications of Pillow Block Bearings in Industries

| Industry | Common Applications | Advantages of Pillow Block Bearings |

|---|---|---|

| Manufacturing | Conveyor systems, processing equipment | Durability, ease of maintenance |

| Agriculture | Farm machinery, irrigation systems | Resistance to harsh conditions |

| Automotive | Drivetrain components, suspension systems | High load capacity, stability |

| Construction | Heavy machinery, cranes | Shock absorption, reliability |

| Mining | Mining equipment, separators | Excellent load distribution |

Maintenance Tips for Ensuring Longevity of Pillow Block Bearings

Pillow block bearings are widely used in machinery. Yet, proper maintenance is key for their longevity. Regular inspections can prevent unexpected failures. Check for unusual noise or vibration. These signs often indicate wear or misalignment.

Lubrication is crucial. Using the right grease helps reduce friction and heat. Too little lubrication can lead to rapid deterioration. Ensure that the grease is not contaminated. Contaminants can affect performance severely. It’s important to find a balance. Over-greasing can cause issues too.

Clean the surrounding areas frequently. Dirt can easily enter the bearing housing. This can accelerate wear and tear. Installation errors should be revisited. Double-check the alignment when replacing bearings. Misalignment can lead to premature failure. Taking these steps may seem tedious. However, they can save time and money in the long run.

Why Choose Pillow Block Bearings for Your Machinery Needs?

This chart illustrates the performance metrics of pillow block bearings, highlighting their load capacity, speed, operating temperature, and maintenance frequency. Understanding these metrics is vital for ensuring the longevity and effective use of pillow block bearings in various machinery applications.

Related Posts

-

Unlocking the Benefits of Self Aligning Pillow Block Bearings in Modern Machinery

-

10 Essential Tips for Choosing Small Pillow Block Bearings for Your Projects

-

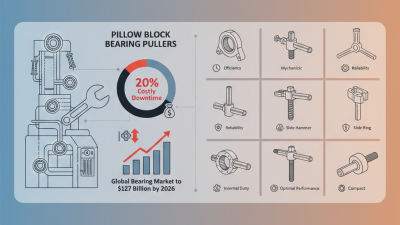

Top 10 Pillow Block Bearing Pullers for Easy Maintenance and Repair

-

2025 How to Choose the Right 25mm Pillow Block Bearing for Your Project

-

Digital Guide to the Best Pillow Block Bearing Types for Your Projects

-

Exploring Innovations in Bearing Factory Production: The Future of Machinery Efficiency