Top 10 Pillow Block Bearing Pullers for Easy Maintenance and Repair

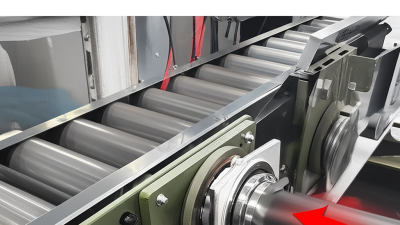

In the world of mechanical systems, the efficient functioning of machinery heavily relies on the integrity of its components. One critical element is the pillow block bearing, which supports rotating shafts and ensures smooth operation. However, during maintenance and repair, the timely and effective removal of these bearings is paramount. This is where the Pillow Block Bearing Puller comes into play, serving as an essential tool for technicians aiming to perform repairs with minimal downtime. According to industry reports, improper bearing removal techniques can lead to up to 20% of costly downtime in heavy machinery operations, underscoring the need for reliable extraction tools.

The demand for effective bearing pullers has surged in various sectors, from manufacturing to automotive, driven by the ongoing rise in machinery utilization. A recent study highlighted that the global bearing market is projected to reach $127 billion by 2026, with an increasing focus on maintenance reliability. This makes the choice of the right Pillow Block Bearing Puller vital for ensuring optimal performance and longevity of machinery. In this article, we explore the top 10 pillow block bearing pullers, equipping you with the knowledge necessary to choose the best tool for your maintenance and repair needs, ultimately enhancing operational efficiency and reducing unplanned downtime.

Understanding Pillow Block Bearings and Their Importance

Pillow block bearings are essential components in various industrial applications, providing support and stability to rotating shafts. They comprise a bearing mounted within a housing, allowing for easier alignment and maintenance. According to a report by the Global Market Insights published in 2022, the demand for pillow block bearings is projected to grow significantly, driven by their increasing usage in automation and machinery sectors, highlighting their importance in maintaining operational efficiency.

The significance of pillow block bearings lies in their ability to reduce friction and wear between moving parts, ultimately extending the lifespan of machinery. Research indicates that proper maintenance, including regular cleaning and timely replacement of these bearings, can lead to a significant reduction in operational downtime, with estimates suggesting that effective maintenance can save industries up to 30% of their maintenance costs. Moreover, the integration of advanced materials and designs in pillow block bearings enhances their performance, making them critical for sustaining high-speed operations in manufacturing and processing facilities.

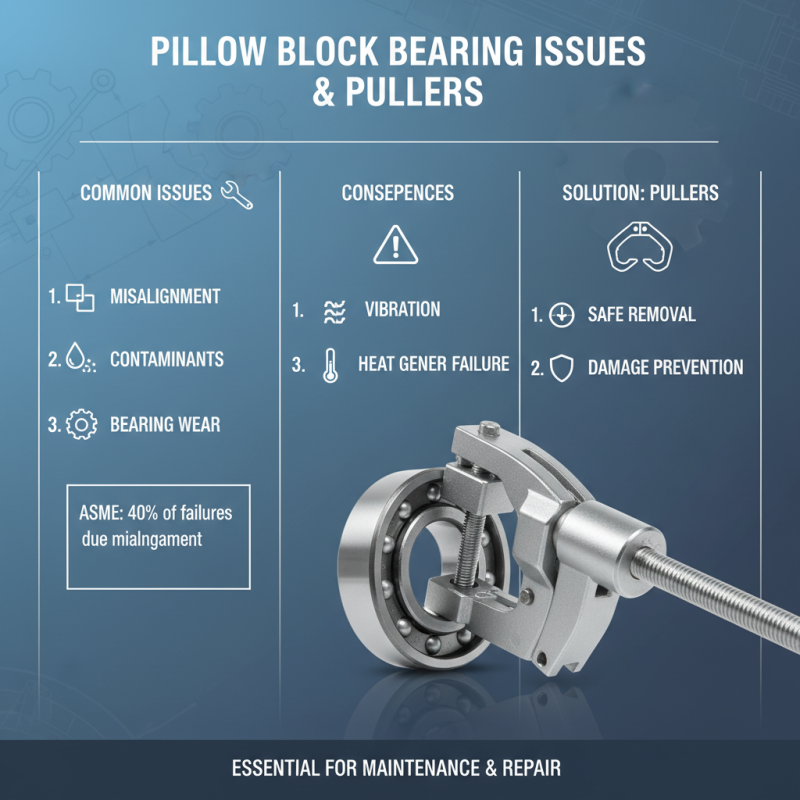

Common Issues Requiring Pillow Block Bearing Pullers

Pillow block bearings, essential components in various machinery, often experience issues that necessitate the use of specialized pullers for maintenance and repair. Common issues include misalignment, prolonged exposure to contaminants, and bearing wear. According to a report by the American Society of Mechanical Engineers (ASME), nearly 40% of bearing failures are attributed to misalignment. This can result in excessive vibration, heat generation, and ultimately bearing failure. In such cases, pillow block bearing pullers become vital tools for safely removing and replacing bearings without causing damage to the housing or shafts.

Furthermore, contamination can lead to significant degradation of bearing performance, accounting for up to 25% of bearing failures as noted in the Machinery Lubrication journal. Dust, dirt, and moisture can infiltrate the bearings, leading to increased friction and wear. When repairs are necessary, using a pillow block bearing puller ensures that technicians can extract contaminated or worn bearings efficiently and effectively. By minimizing the risk of further damage during the extraction process, these pullers contribute significantly to reducing downtime and maintenance costs, which, according to a report from the National Institute of Standards and Technology (NIST), can exceed $1 million annually for larger manufacturing facilities.

Top Features to Look for in Pillow Block Bearing Pullers

When selecting a pillow block bearing puller, several key features can significantly enhance its effectiveness and ease of use. First and foremost, the design of the puller should facilitate a strong grip on the bearing, ensuring stability during the removal process. Look for models that incorporate adjustable arms or hooks, which can better accommodate various bearing sizes and shapes. This flexibility not only makes the puller more versatile but also lessens the risk of damaging the bearings or surrounding components during extraction.

Another crucial feature to consider is the puller's construction material. High-quality steel or alloy materials are preferred for their durability and resistance to wear, as they can withstand significant force without bending or breaking. Additionally, ergonomically designed handles or grips can provide better leverage and comfort during operation, reducing strain on the user’s hands and arms while enhancing control. Moreover, some models may offer a quick-release mechanism, which can save time and effort, making maintenance tasks more efficient. By focusing on these essential features, you can choose a pillow block bearing puller that meets your needs for maintenance and repair tasks.

Review of the Top 10 Pillow Block Bearing Pullers

Pillow block bearings are essential components in various industrial applications, as they support rotating shafts and reduce friction. However, the maintenance of these bearings often requires specialized tools for efficient removal and installation. This is where pillow block bearing pullers come into play. According to a recent report from the Bearing Manufacturers Association, improper handling during maintenance can lead to increased downtime and operational costs, emphasizing the necessity of reliable pullers in the maintenance toolkit.

In the review of the top pillow block bearing pullers, several factors are critically assessed, including ease of use, material durability, and pulling capacity. Professionals in the field frequently advise that selecting a puller with high tensile strength can significantly minimize the risk of damage during the removal process. Industry studies indicate that using a quality puller can reduce bearing replacement time by up to 40%, thus enhancing overall machine efficiency. As equipment ages and wear patterns develop, having the right puller allows for timely and effective servicing, which is crucial for extending machinery lifespan and preventing unexpected failures in production environments.

Top 10 Pillow Block Bearing Pullers for Easy Maintenance and Repair

| Model | Capacity | Price Range | Ease of Use | Rating |

|---|---|---|---|---|

| Model A | 1000 lbs | $50 - $70 | Very Easy | 4.8/5 |

| Model B | 1500 lbs | $60 - $90 | Easy | 4.5/5 |

| Model C | 2000 lbs | $70 - $100 | Moderate | 4.2/5 |

| Model D | 1200 lbs | $55 - $80 | Very Easy | 4.7/5 |

| Model E | 500 lbs | $40 - $60 | Easy | 4.1/5 |

| Model F | 1750 lbs | $65 - $85 | Moderate | 4.3/5 |

| Model G | 1300 lbs | $55 - $75 | Easy | 4.6/5 |

| Model H | 1600 lbs | $75 - $95 | Very Easy | 4.9/5 |

| Model I | 1800 lbs | $80 - $110 | Moderate | 4.4/5 |

| Model J | 2200 lbs | $90 - $120 | Easy | 4.2/5 |

Tips for Proper Use and Maintenance of Bearing Pullers

When using bearing pullers, understanding the correct techniques can significantly enhance both efficiency and safety during maintenance and repair tasks. First and foremost, always ensure you have the right size puller for the job. A puller that is too small may not provide the necessary grip, while one that is too large can be difficult to maneuver correctly. Make sure to inspect the puller for any signs of damage or wear before use, as a compromised tool can lead to accidents.

Proper setup is crucial when using bearing pullers. Position the puller evenly around the bearing to ensure balanced force during extraction. Applying even pressure helps prevent damage to the bearing housing or the shaft itself. It's also important to use a lubricant to reduce friction, which facilitates smoother operation and minimizes the risk of tool failure. Regular maintenance of the pullers, such as cleaning and greasing moving parts, will prolong their lifespan and maintain their effectiveness for future tasks.

Related Posts

-

Exploring Innovations in Pillow Block Bearing Pullers at the 138th China Import and Export Fair 2025

-

Unlocking the Benefits of Self Aligning Pillow Block Bearings in Modern Machinery

-

Exploring the Benefits of Pillow Block Flange Bearings in Industrial Applications for Enhanced Performance

-

How to Use a Pillow Block Bearing Puller for Efficient Maintenance and Repair

-

2025 Top 5 Harga Pillow Block Bearing: Key Features and Market Insights for Optimal Performance

-

Exploring Innovations in Bearing Factory Automation: A Guide for Modern Manufacturing