How to Use a Pillow Block Bearing Puller for Efficient Maintenance and Repair

When it comes to efficient maintenance and repair of machinery, understanding the tools at your disposal can significantly impact the outcome of your work. One essential tool that often goes unnoticed in workshops is the Pillow Block Bearing Puller. This versatile device plays a crucial role in removing and installing bearings housed in pillow blocks, which are widely used in various industrial applications. Utilizing a Pillow Block Bearing Puller not only enhances the speed and ease of these tasks but also reduces the risk of damage to both the bearing and the surrounding components.

Proper techniques and practices in using a Pillow Block Bearing Puller can lead to significant improvements in maintenance routines. By familiarizing yourself with the operation of this tool, you can ensure that your machinery remains in optimal condition, reducing downtime and extending the life of your equipment. This guide aims to provide insights into the efficient use of a Pillow Block Bearing Puller, highlighting key tips and best practices that will enhance your repair endeavors and promote a more streamlined workflow in your mechanical maintenance tasks.

Understanding Pillow Block Bearings and Their Applications

Pillow block bearings play a crucial role in various mechanical applications by providing support and stabilization for rotating shafts. Typically housed in a protective casing, these bearings are designed to absorb significant loads and compensate for shaft misalignment. Commonly utilized in industries such as manufacturing, agriculture, and transportation, pillow block bearings enhance the longevity and reliability of machinery by reducing friction and wear.

The applications of pillow block bearings are diverse, ranging from conveyor systems to industrial fans and pumps. Their design allows for easy installation and maintenance, ensuring that equipment operates smoothly over time. Furthermore, by providing stability and alignment for rotating components, these bearings minimize potential downtime caused by mechanical failures. Understanding their application and functionality is essential for effective maintenance, enabling technicians to perform repairs efficiently and ensure optimal equipment performance.

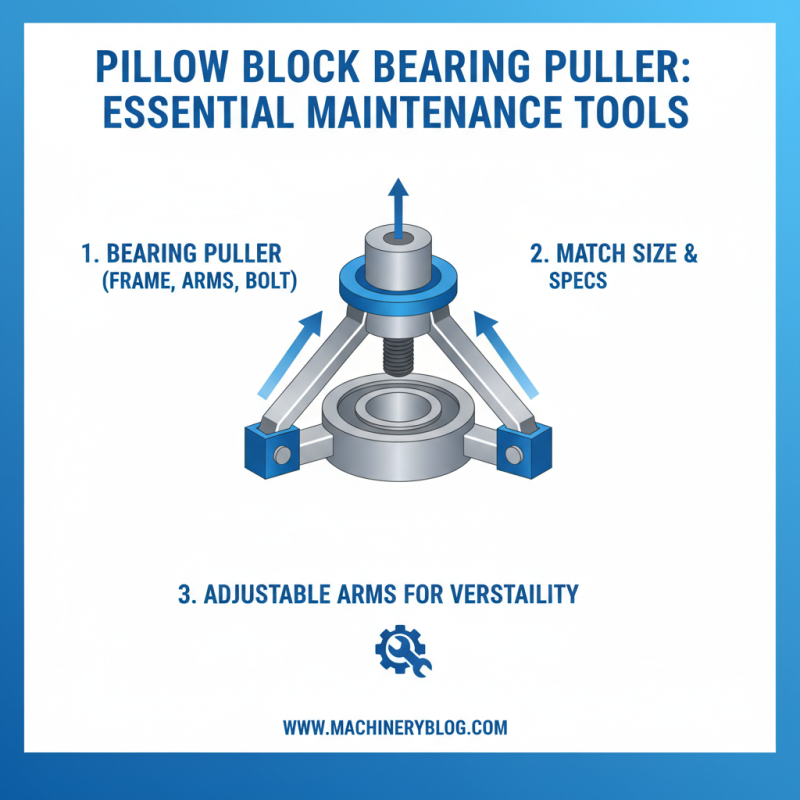

Essential Tools Required for Using a Pillow Block Bearing Puller

When using a pillow block bearing puller, having the right tools on hand is crucial for achieving efficient maintenance and repair. The primary tool required for this process is the bearing puller itself, which typically consists of a frame, arms, and a central bolt for applying force. These pullers come in various sizes, so selecting one that matches the specifications of the bearing you are working on is essential. Additionally, adjustable arms can help accommodate different bearing widths, making the task more versatile.

In addition to the bearing puller, other essential tools include a socket set or wrenches, which are necessary for loosening and tightening nuts and bolts. A torque wrench can ensure that fasteners are tightened to the appropriate specifications, preventing future issues. Moreover, a rubber mallet can be useful in tapping the puller or bearing gently, helping to free stubborn components without causing damage. Lastly, having safety glasses and gloves on hand is crucial to protect yourself while performing repair tasks. By gathering these essential tools, you can effectively use a pillow block bearing puller, leading to a smoother maintenance experience.

Step-by-Step Guide to Safely Remove a Pillow Block Bearing

Removing a pillow block bearing safely requires a careful approach to avoid damage and ensure efficient maintenance. Start by gathering all necessary tools, including a pillow block bearing puller, appropriate wrenches, and personal safety gear such as gloves and eye protection. Before beginning the removal, ensure that the machinery is powered down and securely locked out to prevent accidental movements. This safety step is crucial to protect both the technician and the equipment.

Once safety measures are in place, assess the bearing's condition. Check for signs of wear or damage, which can affect the removal process. Position the pillow block bearing puller around the bearing, ensuring that it is aligned properly for an even pull. Gradually tighten the puller’s center bolt while monitoring the bearing’s response. If resistance is felt, back off slightly and inspect for any obstructions that may be hindering removal. It is important to apply steady, even pressure to avoid damaging the bearing housing. With patience and proper technique, the bearing can be removed without incident, allowing for efficient maintenance or replacement.

Best Practices for Maintaining Pillow Block Bearings

Pillow block bearings are essential components in a wide range of machinery and equipment, providing support to rotating shafts and reducing friction. To ensure their longevity and optimal performance, adopting best practices for their maintenance is crucial. According to a report published by the American Society of Mechanical Engineers (ASME), regular maintenance of pillow block bearings can reduce failure rates by up to 30%, substantially decreasing downtime and repair costs for businesses.

One effective maintenance practice involves a thorough inspection of the bearings regularly. This includes checking for signs of wear, wobbling, or misalignment, which can lead to premature failure. Additionally, maintaining appropriate lubrication levels is critical. A study by the International Society of Tribology revealed that nearly 50% of bearing failures are attributed to inadequate lubrication. Therefore, using quality lubricants and adhering to recommended re-lubrication schedules can enhance the lifespan of pillow block bearings significantly.

Furthermore, environmental factors play a pivotal role in bearing maintenance. Exposure to contaminants such as dirt or moisture can severely impact their function. Implementing protective measures like sealed or shielded designs can mitigate this risk, as evidenced by research from the Bearing Specialists Association, which indicates that well-sealed bearings can last up to 50% longer than those without such protections. By strictly following these best practices, organizations can ensure the reliable performance of pillow block bearings, ultimately leading to more efficient operations.

Maintenance Efficiency of Pillow Block Bearings Using Pullers

This chart illustrates the time efficiency gained from using a pillow block bearing puller during maintenance tasks. The data shows a significant reduction in maintenance time from 10 hours to just 4 hours after implementing the use of a puller, highlighting best practices in maintenance strategies.

Common Mistakes to Avoid When Using a Bearing Puller

When using a pillow block bearing puller, avoiding common mistakes is crucial for effective maintenance and repair.

One frequent error is not properly aligning the puller with the bearing. This misalignment can lead to uneven force application, which may damage both the bearing and the surrounding components. Always ensure that the puller is centered and securely fastened before applying pressure to avoid unnecessary wear or failure.

Another mistake to steer clear of is applying excessive force during the removal process. Many users may think that brute strength is a solution, but this can lead to catastrophic results, such as broken tools or damaged parts. Instead, utilize steady, gradual pressure and monitor the puller's progress. If resistance is felt, consider lubricating the area or reassessing the tool's alignment before proceeding. Proper technique not only enhances efficiency but also prolongs the lifespan of both the puller and the components involved.

Related Posts

-

Exploring Split Pillow Block Bearings at the 138th Canton Fair 2025: Industry Insights and Trends

-

Understanding the Role of Small Pillow Block Bearings in Everyday Machinery

-

Exploring the Advantages of Self Aligning Pillow Block Bearings in Modern Machinery

-

10 Essential Tips for Choosing Small Pillow Block Bearings for Your Projects

-

Top 10 Heavy Duty Pillow Block Bearings for Maximum Performance

-

Digital Guide to the Best Pillow Block Bearing Types for Your Projects