Mastering Mechanical Maintenance: The Essential Guide to Pillow Block Bearing Pullers for Every Workshop

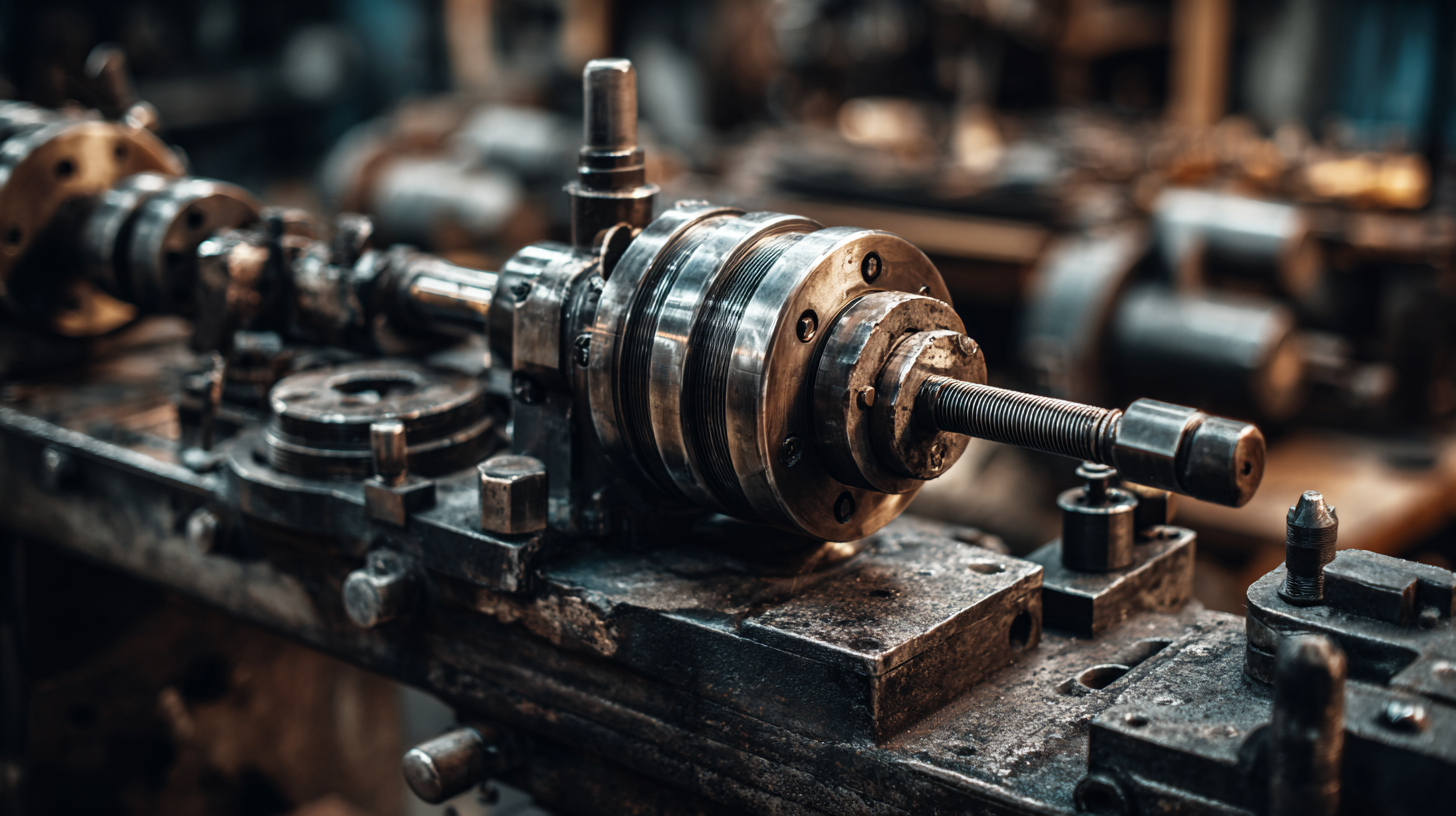

In the dynamic world of mechanical maintenance, the Pillow Block Bearing Puller has emerged as an indispensable tool for workshops aiming to enhance operational efficiency and minimize downtime. According to a recent report from the Journal of Mechanical Engineering, nearly 70% of machinery failures can be attributed to improper bearing installation and maintenance. This statistic underscores the critical role that specialized tools play in ensuring the longevity and reliability of machinery.

By mastering the use of Pillow Block Bearing Pullers, technicians can efficiently remove bearings without causing damage to components, leading to increased productivity and reduced repair costs. Additionally, the global bearing puller market is projected to grow at a CAGR of 5.2% over the next five years, highlighting the growing recognition of the importance of these tools in maintenance practices across various industries. As workshops seek to optimize their processes, understanding the significance and application of Pillow Block Bearing Pullers is essential for any successful maintenance strategy.

By mastering the use of Pillow Block Bearing Pullers, technicians can efficiently remove bearings without causing damage to components, leading to increased productivity and reduced repair costs. Additionally, the global bearing puller market is projected to grow at a CAGR of 5.2% over the next five years, highlighting the growing recognition of the importance of these tools in maintenance practices across various industries. As workshops seek to optimize their processes, understanding the significance and application of Pillow Block Bearing Pullers is essential for any successful maintenance strategy.

Essential Features to Look for in Pillow Block Bearing Pullers

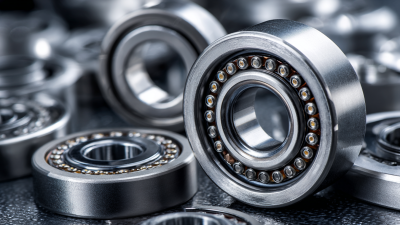

When selecting pillow block bearing pullers for a workshop, it’s crucial to identify the essential features that ensure efficiency and reliability. According to a report by the Machinery Maintenance Association, 35% of equipment failures can be attributed to improper disassembly techniques. Therefore, choosing a puller that offers versatility in handle length, jaw design, and load capacity is paramount. Ideally, a robust pillow block bearing puller should accommodate varying bearing sizes, with jaw designs that provide stable grip to minimize the risk of component damage.

When selecting pillow block bearing pullers for a workshop, it’s crucial to identify the essential features that ensure efficiency and reliability. According to a report by the Machinery Maintenance Association, 35% of equipment failures can be attributed to improper disassembly techniques. Therefore, choosing a puller that offers versatility in handle length, jaw design, and load capacity is paramount. Ideally, a robust pillow block bearing puller should accommodate varying bearing sizes, with jaw designs that provide stable grip to minimize the risk of component damage.

Another vital feature to consider is the material and durability of the puller. High-quality steel construction is recommended, as it offers enhanced strength and resistance to wear, which can significantly extend the life of the tool. A recent study by the Equipment Reliability Institute indicates that tools made from premium materials reduce maintenance costs by as much as 20% over five years. Furthermore, ergonomic designs can improve user comfort and reduce fatigue, enhancing overall productivity in the workshop setting. Selecting pullers with these essential features not only ensures effective maintenance practices but also contributes to long-term operational efficiency.

Top 5 Benefits of Using Pillow Block Bearing Pullers in Workshops

Pillow block bearing pullers are invaluable tools for any workshop focusing on mechanical maintenance. One of the primary benefits of using these pullers is their ability to reduce downtime during machinery maintenance. According to a study by the American Society of Mechanical Engineers (ASME), effective use of bearing pullers can cut maintenance time by up to 30%, allowing for faster repairs and minimizing production disruptions. This efficiency is crucial in industries where time equates to significant financial loss.

Another significant advantage is the improved safety they provide. Industry reports from the Occupational Safety and Health Administration (OSHA) indicate that improper bearing removal techniques can lead to accidents, resulting in over 1,000 reported injuries annually. Pillow block bearing pullers mitigate these risks by ensuring an even and controlled extraction process, reducing the chances of sudden component failures or injuries to the technicians. Furthermore, the ergonomic design of many pullers reduces the physical strain on workers, promoting a safer working environment.

Lastly, utilizing pillow block bearing pullers can lead to cost savings in the long run. A report from the Mechanical Maintenance Research Association (MMRA) highlighted that workshops employing high-quality pullers saw a 20% reduction in repair costs, as they could perform jobs efficiently without damaging the bearings or surrounding equipment. This not only extends the lifespan of components but also reduces the frequency of replacements and the associated costs.

7 Common Mistakes to Avoid When Using Bearing Pullers

When using bearing pullers, avoiding common mistakes is essential to ensure both safety and efficiency. One frequent error is improper tool selection. Not every puller is suitable for every bearing size or type. It's crucial to choose the right puller that matches the specifications of the bearing you're working on. Using the incorrect puller can lead to damage and inefficient operation.

Another mistake is inadequate lubrication. Without proper lubrication, the bearing puller can become stuck, causing frustration and potential damage to the components. Always ensure that both the puller and the bearing are properly lubricated before attempting to remove them. This will facilitate a smoother extraction process.

Additionally, neglecting to secure the workspace can lead to accidents. A cluttered or unstable work area significantly increases the risk of injury when using heavy tools like bearing pullers. Keep your workspace organized and ensure that all necessary tools are within easy reach. Following these tips will enhance safety and improve your mechanical maintenance tasks effectively.

Mastering Mechanical Maintenance: The Essential Guide to Pillow Block Bearing Pullers for Every Workshop - 7 Common Mistakes to Avoid When Using Bearing Pullers

| Mistake | Description | Impact | Prevention |

|---|---|---|---|

| Not Using Proper Method | Failing to follow the correct removal techniques can damage the bearing. | Increased wear and premature failure of components. | Consult the manufacturer's guidelines before proceeding. |

| Using Inappropriate Tools | Using tools not designed for the specific type of bearing puller needed. | Potential for tool breakage and damage to bearings. | Always match tools to the specifications required for the task. |

| Insufficient Lubrication | Neglecting to lubricate the puller can cause added friction. | Overheating and possible damage to both pulling tool and bearings. | Use appropriate lubricants on tools before use. |

| Applying Uneven Force | Using pullers incorrectly can lead to uneven load distribution. | Cracked or damaged bearings, excessive wear. | Ensure even and balanced force is applied when pulling. |

| Ignoring Safety Precautions | Not using safety gear while operating pullers. | Risk of injury from flying components. | Always wear safety goggles and gloves when working. |

| Neglecting Inspection | Failing to inspect tools for wear and tear before use. | Increased likelihood of tool failure during operation. | Regularly check the condition of pullers before use. |

| Lack of Training | Untrained personnel improperly using bearing pullers. | Increases risk of accidents and equipment damage. | Provide proper training for all personnel who will use pullers. |

The Ultimate Comparison: Manual vs. Hydraulic Pillow Block Bearing Pullers

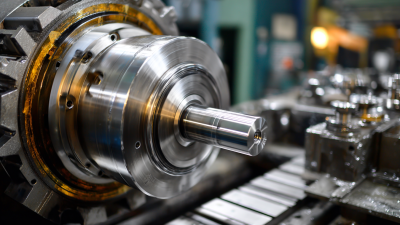

When it comes to removing pillow block bearings, the choice between manual and hydraulic pullers can significantly impact efficiency and ease of use in any workshop. Manual pillow block bearing pullers are often favored for their simplicity and affordability. They require no external power source, making them portable and easy to handle. However, the drawback lies in the physical effort required, which can become a limiting factor when dealing with larger or more stubborn bearings. For small to medium-sized jobs, a manual puller can be a practical solution, as long as the user is prepared for the manual labor involved.

On the other hand, hydraulic pillow block bearing pullers offer superior power and ease of operation, particularly in heavy-duty applications. These pullers leverage hydraulic pressure to effortlessly extract bearings, reducing the risk of damage to both the bearing and the housing. Consequently, they save time and increase productivity in workshops where multiple bearings must be replaced regularly. While hydraulic pullers tend to be more expensive and may require maintenance, their efficiency and effectiveness make them a worthwhile investment for performance-oriented environments where precision and speed are paramount.

10 Maintenance Tips for Extending the Life of Your Bearing Pullers

Pillow block bearing pullers are essential tools in mechanical maintenance, enabling technicians to remove bearings with precision and ease. To ensure that these tools remain effective over time, proper maintenance is crucial. First, regularly inspect the pullers for any signs of wear and tear. Check for rust or corrosion, especially on the bearing surfaces, and clean any buildup that may impair performance. A clean puller not only functions better but also prolongs its lifespan.

Pillow block bearing pullers are essential tools in mechanical maintenance, enabling technicians to remove bearings with precision and ease. To ensure that these tools remain effective over time, proper maintenance is crucial. First, regularly inspect the pullers for any signs of wear and tear. Check for rust or corrosion, especially on the bearing surfaces, and clean any buildup that may impair performance. A clean puller not only functions better but also prolongs its lifespan.

Lubrication is another key factor in maintaining bearing pullers. Use high-quality grease to lubricate moving parts, which helps to reduce friction and prevent overheating during use. It is advisable to apply lubricant regularly, particularly if the pullers are used in a harsh environment. Additionally, when storing the pullers, keep them in a dry, clean area to prevent contamination and damage. Following these maintenance tips will ensure that your pillow block bearing pullers remain reliable tools in your workshop for years to come.

Related Posts

-

Exploring Innovations in Pillow Block Bearing Pullers at the 138th China Import and Export Fair 2025

-

What You Need to Know About 25mm Pillow Block Bearing

-

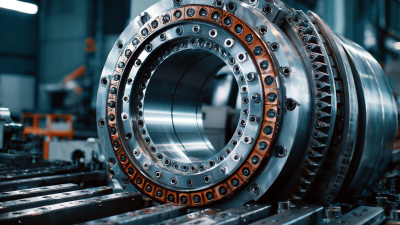

Exploring the Science Behind Bearing Manufacturing: Innovations in Bearing Factory Processes

-

How to Choose the Right Roller Bearing for Optimal Performance and Longevity in Your Machinery

-

How to Choose the Right Stainless Steel Bearing for Your Application

-

Exploring Innovations in Bearing Factory Production: The Future of Machinery Efficiency