The Innovative Future of Bearing Factories and Their Role in Modern Technology

The bearing industry is witnessing a transformative shift as advanced technologies pave the way for innovative bearing factories that play a pivotal role in modern manufacturing. According to the Global Bearing Market Report, the industry is projected to reach a valuation of $103 billion by 2027, highlighting the growing demand for high-performance bearings across various sectors, including automotive, aerospace, and renewable energy. This surge is driven by the need for efficiency and reliability in machinery, where superior bearing solutions can significantly enhance equipment longevity and performance.

As the bearing factory of the future evolves, automation, IoT integration, and sustainability will be at the forefront of operational strategies. The McKinsey report on Industry 4.0 indicates that manufacturing companies adopting smart technologies can improve productivity by up to 30%. This not only optimizes the production processes of bearing factories but also ensures a competitive edge in an ever-evolving global market. With a focus on precision engineering and eco-friendly practices, bearing factories are positioned to contribute substantially to modern technology's innovative landscape, setting new standards for quality and efficiency in the manufacturing domain.

The Evolution of Bearing Factories in the Age of Automation

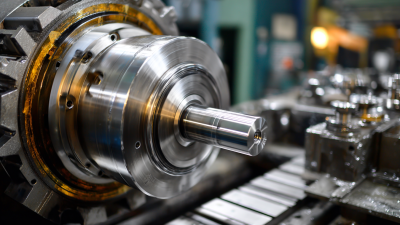

The evolution of bearing factories in the age of automation marks a significant transformation in manufacturing processes. Traditionally, bearing production was labor-intensive and relied heavily on manual oversight. However, the integration of advanced technologies such as robotics, artificial intelligence, and IoT has revolutionized how these factories operate. Automation has streamlined production lines, increased precision, and reduced human error, leading to higher quality bearings that meet the demands of modern applications.

Furthermore, the push towards smart manufacturing has allowed bearing factories to utilize data analytics for optimizing operations. Sensors embedded in machinery provide real-time feedback, enabling proactive maintenance and minimizing downtime. This not only enhances productivity but also fosters a more sustainable approach to manufacturing as resources are utilized more efficiently. As automation continues to advance, the role of bearing factories will increasingly align with the principles of Industry 4.0, ensuring their relevance in a rapidly changing technological landscape.

The Innovative Future of Bearing Factories and Their Role in Modern Technology

| Dimension | Description | Current Trends | Future Prospects |

|---|---|---|---|

| Automation Integration | Increasing use of robotics and automated systems in manufacturing processes. | Enhanced precision and reduced human error in production. | Widespread adoption of AI for predictive maintenance and real-time monitoring. |

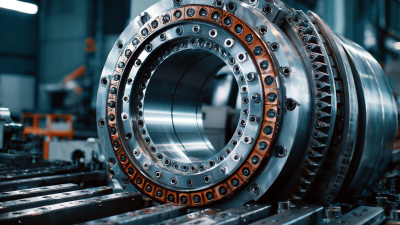

| Materials Innovation | Development of advanced materials such as composites and ceramics. | Improved durability and performance characteristics of bearings. | Emergence of materials with self-lubricating properties. |

| Sustainability Practices | Focus on reducing waste and energy consumption in manufacturing. | Implementation of circular economy practices and recycling of materials. | Integration of eco-friendly technologies and renewable resources in production. |

| Digitalization | Transition to smart factories with interconnected devices. | Real-time data analytics for improved decision-making and efficiency. | Full implementation of Industry 4.0 principles to enhance productivity. |

| Global Supply Chain Optimization | Streamlining supply chain processes through technology. | Use of blockchain for transparency and traceability. | Increased resilience and flexibility in supply chain management. |

The Integration of Smart Technology in Bearing Production

The integration of smart technology in bearing production marks a pivotal advancement in the manufacturing sector. By incorporating IoT sensors and artificial intelligence, bearing factories can now monitor equipment performance in real-time, enhancing overall efficiency. These technologies provide manufacturers with actionable insights, allowing for proactive maintenance and reduced downtime. Moreover, smart technology facilitates precision in the production process, ensuring that bearings meet stringent quality standards while minimizing waste.

The integration of smart technology in bearing production marks a pivotal advancement in the manufacturing sector. By incorporating IoT sensors and artificial intelligence, bearing factories can now monitor equipment performance in real-time, enhancing overall efficiency. These technologies provide manufacturers with actionable insights, allowing for proactive maintenance and reduced downtime. Moreover, smart technology facilitates precision in the production process, ensuring that bearings meet stringent quality standards while minimizing waste.

In addition to optimizing manufacturing processes, the use of smart technology fosters greater flexibility and customization in bearing designs. Advanced software enables engineers to simulate and analyze various design parameters, leading to innovative products tailored to specific applications. This adaptability not only meets the evolving demands of industries such as automotive and aerospace but also supports sustainable practices by reducing energy consumption and material usage. The future of bearing manufacturing is thus intricately linked with these technological advancements, reshaping the industry into a more responsive and environmentally conscious sector.

Sustainability Practices in Modern Bearing Manufacturing

As the bearing manufacturing industry continues to evolve, sustainability practices have emerged as a cornerstone of modern production processes. According to a report by Research and Markets, the global bearing market is projected to reach $104.5 billion by 2027, with a growing emphasis on environmentally friendly manufacturing techniques. This shift is spurred by increasing regulatory pressures and consumer demand for greener products. Manufacturers are investing in energy-efficient machinery and processes, which have been proven to reduce energy consumption by up to 30%, ultimately lowering carbon footprints.

Moreover, innovative approaches such as life cycle analysis (LCA) are being adopted to assess the environmental impacts of bearings from raw material extraction through to end-of-life disposal. For instance, the Bearing Manufacturers Association has indicated that implementing sustainable materials can cut overall waste by 20-25%. Additionally, companies are exploring the use of biodegradable and recyclable materials, positioning themselves as leaders in sustainability while meeting the stringent requirements of companies committed to reducing their environmental impact. Embracing these practices not only enhances profitability but also reinforces a company's reputation as a responsible player in the global market.

Exploring the Impact of Bearing Innovation on Global Industries

The impact of bearing innovation on global industries is both profound and far-reaching. According to a report by Grand View Research, the global bearing market was valued at approximately $80 billion in 2020 and is projected to grow at a compound annual growth rate (CAGR) of 6.7% from 2021 to 2028. This growth is driven by increasing demands for energy-efficient machinery and the adoption of advanced technologies, such as electric vehicles and renewable energy systems. Innovations in bearing design, materials, and manufacturing processes are crucial to enhance performance, reduce friction, and improve the overall longevity of bearings, which are essential components in various sectors including automotive, aerospace, and industrial machinery.

Moreover, the integration of smart technologies into bearing systems illustrates the synergy between innovation and industry needs. A study by Mordor Intelligence indicates that the smart bearing market alone is expected to reach $2 billion by 2025, highlighting the increasing importance of data analytics and IoT in predictive maintenance and operational efficiency. Enhanced bearing technologies enable manufacturers to monitor wear and tear in real-time, thus reducing downtime and maintenance costs significantly. As industries adapt to these advancements, the role of bearing factories evolves, positioning them at the forefront of technological advancement and sustainability in modern manufacturing practices.

The Future Workforce in Bearing Factories: Skills and Training Needs

As bearing factories evolve within the context of modern technology, the demand for a highly skilled workforce becomes increasingly critical. The integration of artificial intelligence (AI) and robotics into production processes is reshaping job roles and necessitating new skill sets. According to recent reports, up to 85 million jobs may be displaced by automation by 2025, while simultaneously, 97 million new roles more suited to the new division of labor may emerge. This underscores the urgent need for upskilling in the manufacturing sector, particularly in bearing production, where precision and technological integration are paramount.

To adapt, bearing manufacturers must focus on comprehensive training programs targeting both technical abilities and digital competencies. The European Union's initiatives to upskill workers highlight a growing recognition that the future workforce requires a blend of traditional craftsmanship and modern technological know-how. Skills-based hiring is becoming essential, as it aligns employee capabilities with the dynamic needs of the industry. In this rapidly changing landscape, effective communication and training strategies will engage a diverse workforce, ensuring that all employees are equipped to thrive in an increasingly automated environment, paving the way for innovation within bearing factories.

Related Posts

-

Exploring the Science Behind Bearing Manufacturing: Innovations in Bearing Factory Processes

-

Exploring Innovations in Bearing Factory Automation: A Guide for Modern Manufacturing

-

Exploring Split Pillow Block Bearings at the 138th Canton Fair 2025: Industry Insights and Trends

-

Exploring Innovations in Bearing Factory Production: The Future of Machinery Efficiency

-

Understanding the Role of Small Pillow Block Bearings in Everyday Machinery

-

Unlocking the Benefits of Self Aligning Pillow Block Bearings in Modern Machinery