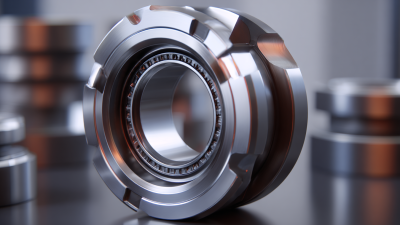

Exploring Innovations in Bearing Factory Production: The Future of Machinery Efficiency

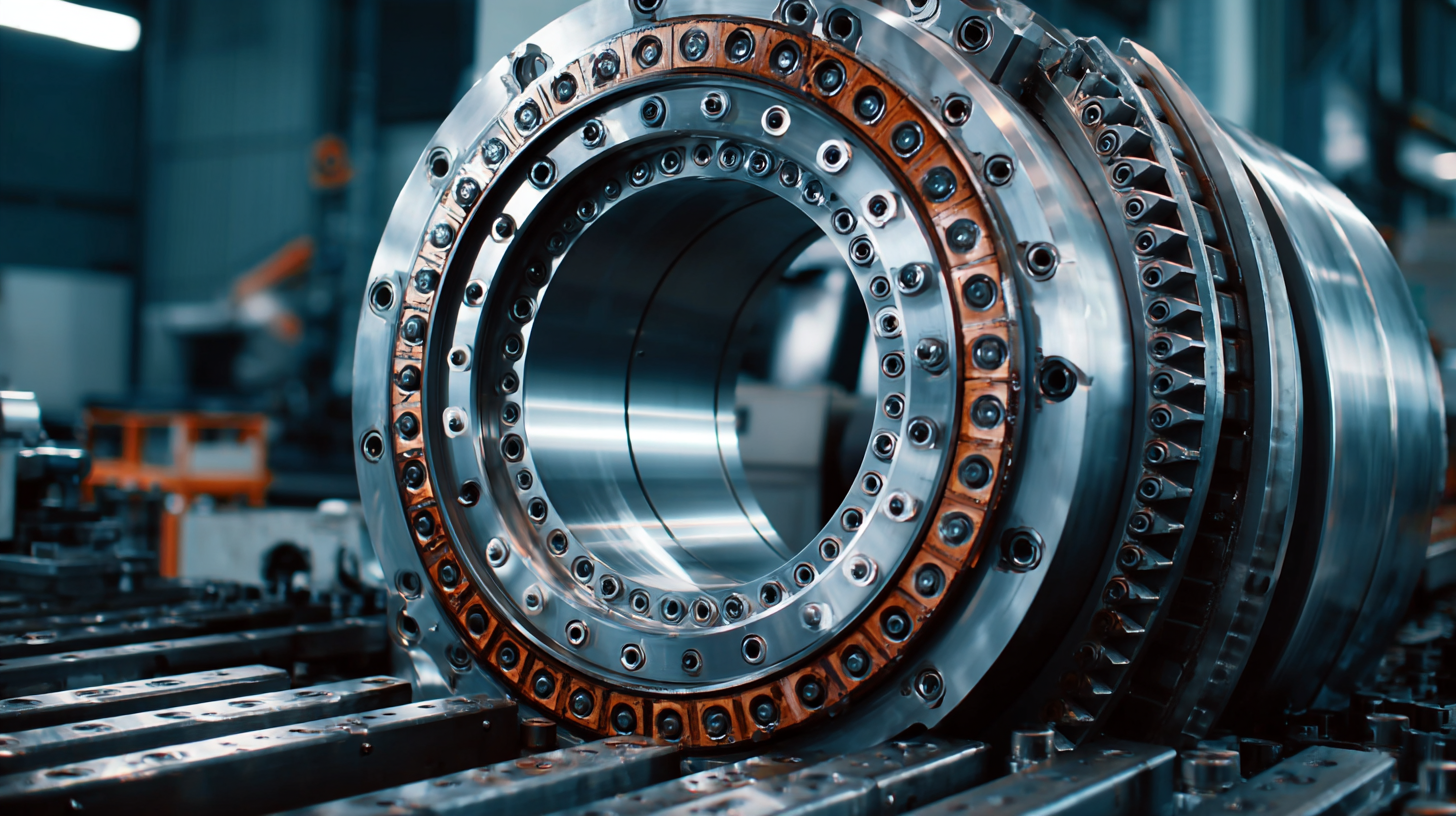

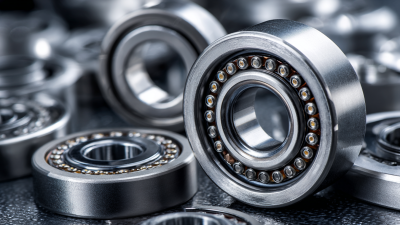

The bearing industry is experiencing a transformative shift as manufacturers increasingly adopt innovative production techniques to enhance machinery efficiency. Recent studies from the National Bearing Association reveal that over 70% of leading bearing factories are implementing automation solutions, resulting in up to a 40% increase in production efficiency. As global demand for high-performance bearings rises, driven by advancements in sectors such as automotive and renewable energy, bearing factories are under pressure to optimize their operations. The integration of smart technologies such as IoT and AI-driven analytics offers promising pathways for predictive maintenance and quality control. This article delves into the future of bearing factory production, exploring the latest innovations that are poised to redefine the machinery landscape, ultimately leading to improved competitiveness and sustainability in the industry.

Innovative Technologies Transforming Bearing Production Efficiency

The bearing production industry is undergoing a significant transformation, driven by innovative technologies that enhance efficiency and sustainability. A recent report highlighted that the global bearings market is projected to reach $200 billion by 2025, fueled by advancements in manufacturing technologies and a growing emphasis on reducing operational costs. Embracing energy-efficient methods and materials not only improves production outputs but also aligns with the global push towards sustainable practices.

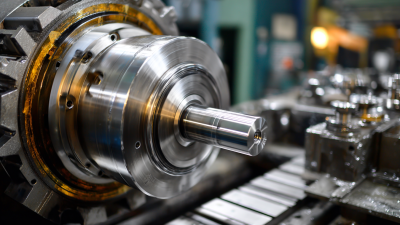

One of the most promising innovations in this field is the integration of artificial intelligence (AI) and machine learning technologies. By leveraging predictive maintenance and data analytics, manufacturers can optimize their production processes, significantly reducing downtime and resource wastage. Reports suggest that AI can increase manufacturing efficiency by up to 20%, showcasing its potential to transform bearing production. Companies are now adopting hybrid technologies that combine traditional craftsmanship with modern automation, reinforcing the trajectory towards greener manufacturing practices while meeting the demands of various sectors reliant on high-performance bearings.

Impact of Digitalization on Manufacturing Operations in the Bearing Industry

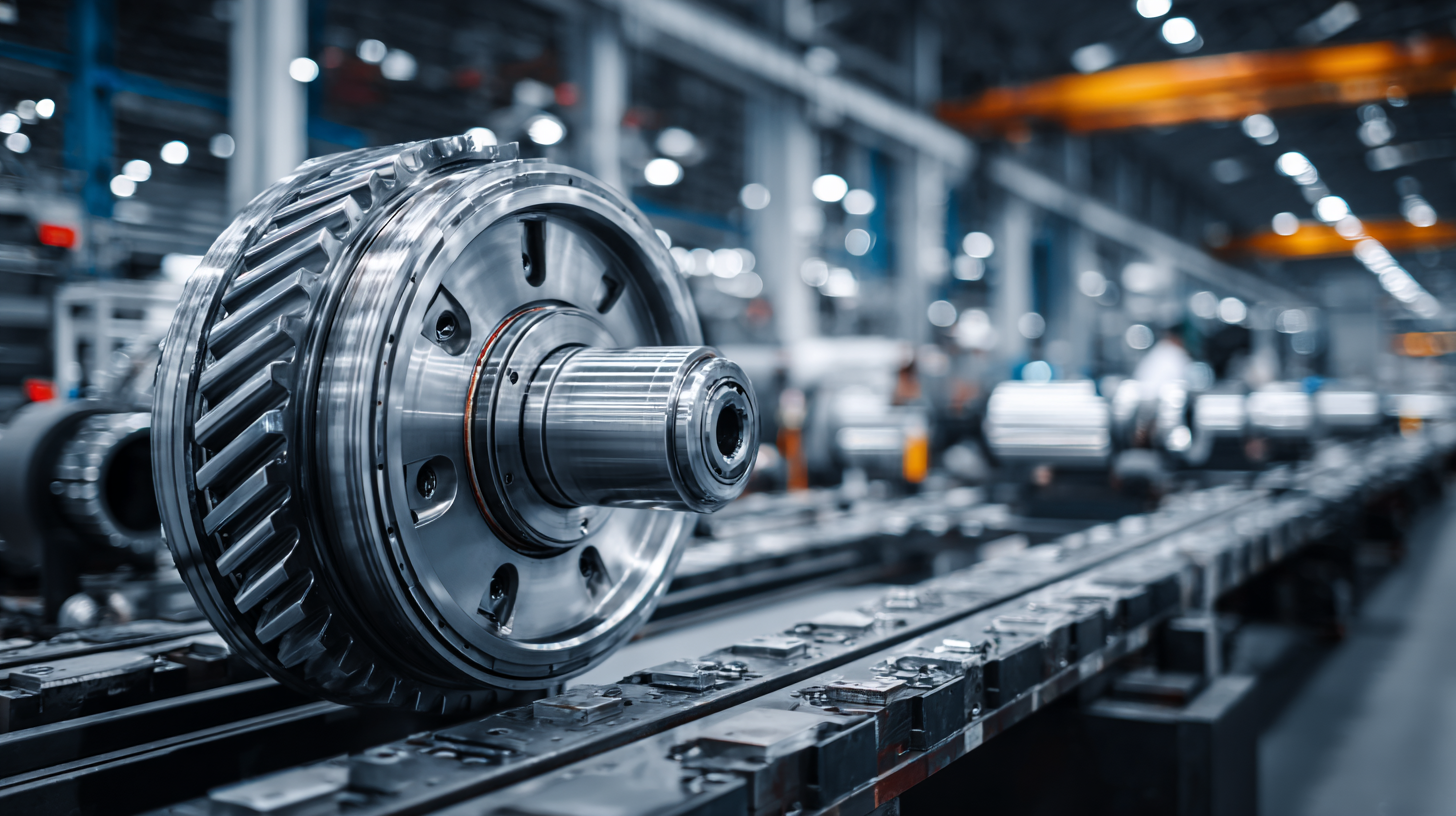

The bearing industry is undergoing a transformative phase, shaped significantly by digitalization. As manufacturers adopt advanced technologies such as the Internet of Things (IoT), artificial intelligence (AI), and real-time data analytics, the efficiency of manufacturing operations is being elevated to unprecedented levels. Digital tools enable seamless connectivity throughout the production line, allowing for smarter decision-making informed by data-driven insights. This transition not only optimizes operational workflows but also enhances the ability to predict maintenance needs, preventing costly downtimes.

Moreover, the integration of digital technologies fosters a culture of continuous improvement in the bearing industry. Automation of routine tasks frees up skilled workers to focus on more complex challenges, driving innovation in product development and process efficiency. The real-time tracking of production metrics empowers manufacturers to adjust processes instantly, ensuring that quality control is consistently upheld. As a result, digitalization is not merely an upgrade of existing practices but a fundamental shift that propels the industry towards a more sustainable and competitive future.

Data-Driven Insights: Metrics for Measuring Production Effectiveness

In the rapidly evolving world of manufacturing, data-driven insights are pivotal for enhancing production effectiveness in bearing factories. According to a report by McKinsey & Company, companies that leverage advanced analytics have seen productivity improvements of 10-20%. By implementing real-time monitoring systems, manufacturers can track key performance metrics such as Overall Equipment Effectiveness (OEE), which combines availability, performance, and quality. This holistic view enables factories to pinpoint inefficiencies and streamline operations.

Moreover, the adoption of IoT technology in machinery has been shown to enhance predictive maintenance capabilities. According to a study by Deloitte, organizations utilizing data analytics for maintenance decision-making experience 25% fewer unexpected failures. Leveraging historical and real-time data allows factories to optimize their machinery uptime and reduce repair costs. These innovations not only boost efficiency but also contribute to significant cost savings, reinforcing the need for manufacturers to embrace a data-centric approach for future production challenges.

Exploring Innovations in Bearing Factory Production: The Future of Machinery Efficiency

| Metric | Value | Industry Average | Notes |

|---|---|---|---|

| Overall Equipment Effectiveness (OEE) | 85% | 75% | Above average efficiency |

| Production Downtime | 5% of total time | 8% | Effective maintenance strategies |

| First Pass Yield (FPY) | 90% | 85% | High quality control |

| Cycle Time | 45 seconds/unit | 50 seconds/unit | Improved automation |

| Scrap Rate | 2% | 4% | Enhanced material quality |

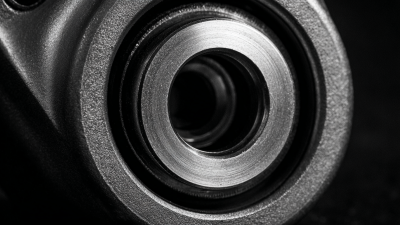

Sustainability Trends in Bearing Manufacturing: Energy Efficiency and Waste Reduction

The bearing manufacturing industry is undergoing significant transformations driven by sustainability trends. One of the primary focuses is on energy efficiency, wherein factories are adopting advanced technologies to reduce energy consumption. Innovative machinery, such as high-efficiency motors and automated systems, are being integrated into production lines to optimize performance while minimizing energy waste. By implementing real-time monitoring systems, manufacturers can adjust their energy use based on the production demand, ensuring efficient operation without compromising product quality.

Waste reduction is another critical aspect of sustainable practices in bearing manufacturing. Organizations are now embracing circular economy principles, which prioritize the reuse and recycling of materials to decrease overall waste. Furthermore, manufacturers are employing precise machining techniques and advanced materials that generate less scrap during production. As a result, companies are not only reducing their environmental impact but also benefiting economically through cost savings associated with lower material and disposal expenses. This commitment to sustainability not only enhances the efficiency of machinery but also positions bearing manufacturers as responsible stewards of the environment, appealing to eco-conscious consumers and stakeholders alike.

Future Trends: The Integration of AI and IoT in Machinery Production Processes

The integration of artificial intelligence (AI) and the Internet of Things (IoT) in machinery production processes is set to redefine the landscape of manufacturing, particularly in bearing factories. By leveraging these technologies, factories can achieve unprecedented levels of efficiency, precision, and automation. AI algorithms can optimize production schedules, predict maintenance needs, and enhance quality control by analyzing data from machinery in real time. This means fewer downtimes, reduced waste, and better product quality, ultimately leading to increased competitiveness in the market.

The integration of artificial intelligence (AI) and the Internet of Things (IoT) in machinery production processes is set to redefine the landscape of manufacturing, particularly in bearing factories. By leveraging these technologies, factories can achieve unprecedented levels of efficiency, precision, and automation. AI algorithms can optimize production schedules, predict maintenance needs, and enhance quality control by analyzing data from machinery in real time. This means fewer downtimes, reduced waste, and better product quality, ultimately leading to increased competitiveness in the market.

Tips for implementing AI and IoT in production include starting small with pilot projects to test technology integration, ensuring robust data management systems are in place to handle the influx of data, and fostering a culture of continuous learning among employees. Additionally, collaborating with technology providers can help manufacturers stay at the forefront of innovation while minimizing risks and costs.

As the trend towards smart manufacturing accelerates, factories that embrace AI and IoT will not only streamline their operations but also unlock new possibilities for product innovation and customization. Engaging properly with these technologies will position manufacturers to respond quickly to market demands and emerging challenges, making them leaders in the bearing industry.

Related Posts

-

How to Choose the Right Roller Bearing for Optimal Performance and Longevity in Your Machinery

-

Exploring the Science Behind Bearing Manufacturing: Innovations in Bearing Factory Processes

-

How to Choose the Right Stainless Steel Bearing for Your Application

-

How to Choose the Right Cast Steel Block Bearing for Your Industrial Needs

-

Exploring Innovations in Pillow Block Bearing Pullers at the 138th China Import and Export Fair 2025

-

What You Need to Know About 25mm Pillow Block Bearing