Top 10 Heavy Duty Pillow Block Bearings for Maximum Performance

In the world of industrial machinery, the significance of Heavy Duty Pillow Block Bearings cannot be overstated. As industries strive for maximum performance and reliability, these robust components play a vital role in ensuring smooth operations across various applications. According to industry expert Dr. Emily Carter, "The right choice of Heavy Duty Pillow Block Bearings can elevate a machine's performance and longevity, minimizing downtime and enhancing productivity." Her insights underscore the importance of selecting the best bearings to meet specific operational demands.

Heavy Duty Pillow Block Bearings are designed to withstand extreme conditions, making them essential for high-load and high-speed applications. As manufacturing environments become increasingly demanding, the need for durable, efficient, and reliable bearing solutions has never been greater. This article explores the top 10 options available in the market, highlighting their performance characteristics, suitability for various applications, and the technological advancements that make them indispensable in today’s industrial landscape. Whether in heavy machinery, conveyor systems, or critical rotating equipment, these bearings are crucial to achieving optimal performance and ensuring operational excellence.

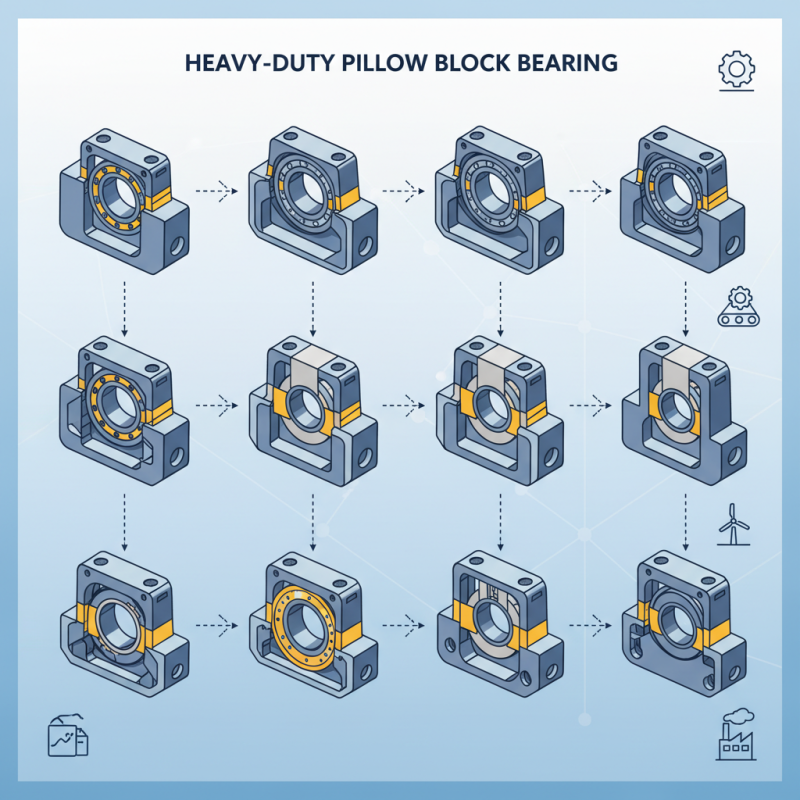

Overview of Heavy Duty Pillow Block Bearings

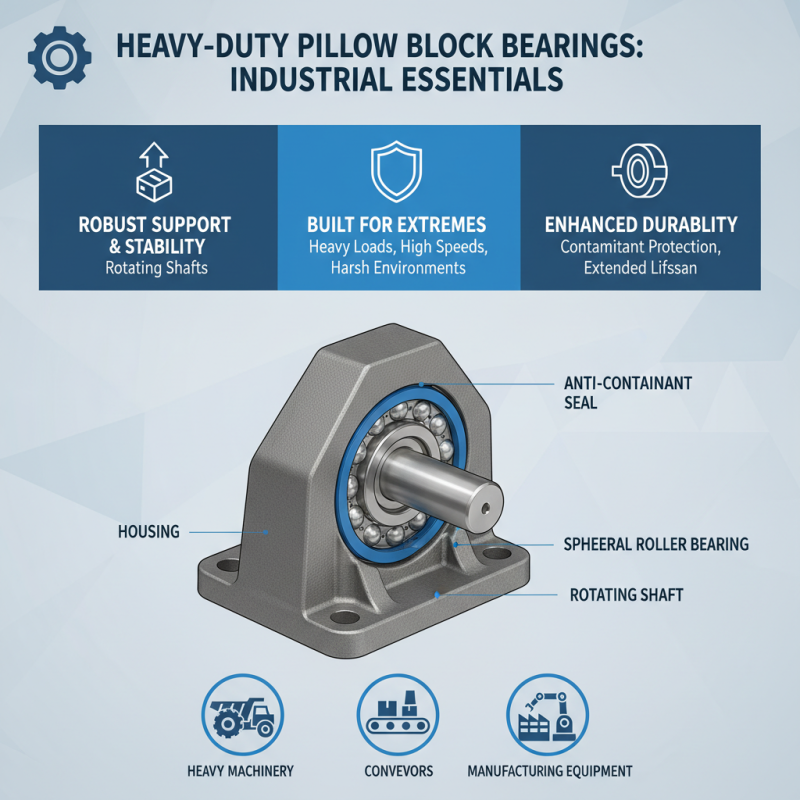

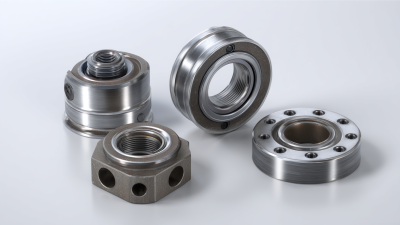

Heavy duty pillow block bearings are essential components in various industrial applications, providing robust support and stability for rotating shafts. These bearings are designed to handle heavy loads, high speeds, and harsh operating environments, making them ideal for heavy machinery, conveyors, and manufacturing equipment. Their unique design typically includes a housing that protects the bearing from contaminants, extending its lifespan and maintaining optimal performance.

When selecting heavy duty pillow block bearings, it’s crucial to consider the load capacity and operating conditions. Ensure the bearing can adequately support the application’s weight without excessive wear. Additionally, pay attention to the materials used in the bearing and housing construction, as these will impact durability and resistance to environmental factors like moisture and dust.

**Tips:** Regular maintenance is vital for the longevity of pillow block bearings. Inspect them for signs of wear and lubricate periodically to minimize friction and heat buildup. Additionally, ensuring proper alignment during installation can greatly enhance performance and prevent premature failure. Always consult with a specialist when in doubt about the specifications needed for your application.

Key Features to Consider When Selecting Pillow Block Bearings

When selecting heavy duty pillow block bearings, there are several key features to consider to ensure maximum performance. One of the most critical factors is the bearing material, which should provide high resistance to wear and corrosion. Materials like cast iron and stainless steel are often preferred for their durability and ability to withstand harsh operating conditions. Additionally, the load capacity is essential; the bearing must be able to handle the anticipated loads without compromising performance. Make sure to evaluate the dynamic and static load ratings to find an appropriate match for your application.

Another important aspect to consider is the lubrication method. Choosing the right type of lubrication can significantly enhance the longevity and efficiency of the bearing. Some pillow block bearings come with built-in lubrication systems, while others may require manual lubrication. It's also vital to assess the bearing's sealing mechanisms, as effective seals can prevent contamination from dirt and moisture, further extending the bearing's life. Finally, consider the mounting options and alignment characteristics; proper installation is crucial for maintaining optimal performance and reducing wear over time.

Top 10 Heavy Duty Pillow Block Bearings Reviewed

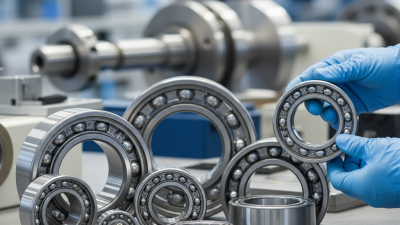

When it comes to heavy-duty applications, selecting the right pillow block bearing is crucial for maximizing performance and ensuring the longevity of your machinery. Pillow block bearings support a rotating shaft and are designed to withstand heavy loads while maintaining alignment. The top ten heavy-duty options reviewed provide a blend of durability, efficiency, and reliability, making them suitable for various industrial applications. Each bearing boasts unique features that enhance performance under high-stress conditions.

Tips for choosing the right pillow block bearings include assessing the load capacity and speed requirements specific to your application. Consider the material composition of the bearing, as materials like cast iron or steel can offer different levels of durability and resistance to environmental factors. Additionally, ensure the mounting type aligns with your machinery, as this can significantly impact the overall performance and ease of installation.

Regular maintenance is essential for maximizing the lifespan of your pillow block bearings. Inspections should be routine to check for signs of wear, such as excessive play or unusual noises. Proper lubrication can significantly reduce friction, and adapting a maintenance schedule based on operating conditions can help keep the bearings in optimal working condition.

Applications for Heavy Duty Pillow Block Bearings in Industry

Heavy duty pillow block bearings play a crucial role in various industrial applications due to their robust design and ability to handle heavy loads. These bearings are particularly favored in sectors such as manufacturing, construction, and transportation where equipment is subjected to severe operational conditions. Their ability to support shafts, accommodate misalignment, and reduce vibration makes them essential for machinery like conveyors, crushers, and large electric motors, ensuring smooth and efficient operation in challenging environments.

In the agricultural sector, heavy duty pillow block bearings are critical for the reliable functioning of machinery such as plows, harvesters, and tillers. These bearings enhance the durability and efficiency of equipment by minimizing wear and tear, thereby extending the lifespan of machinery. Additionally, they are employed in the mining industry to support the heavy and often continuous use of equipment like feeders and screens, where reliability is paramount. The ability to function effectively in high-temperature and dusty conditions further underscores the importance of these bearings, making them indispensable in many industrial scenarios.

Top 10 Heavy Duty Pillow Block Bearings Performance Comparison

The chart above illustrates the load capacity of the top 10 heavy duty pillow block bearings, providing insights into their performance capabilities across various industrial applications. By comparing their load capacities, users can make informed decisions based on their specific operational requirements.

Maintenance Tips for Maximizing Performance of Pillow Block Bearings

Proper maintenance is essential for maximizing the performance of pillow block bearings. Regular inspections should be conducted to check for wear and tear. Pay attention to the alignment of the bearings; misalignment can lead to premature degradation. Ensure the mounting surfaces are clean and free from debris, as any contamination can affect the bearing's functionality. Additionally, it's crucial to monitor the operating temperature, as excessive heat may indicate lubrication issues or overload.

Lubrication plays a significant role in the lifespan of pillow block bearings. Use the recommended type of lubricant, and maintain a consistent lubrication schedule to ensure that the bearings are adequately coated. Avoid over-lubricating, as this can cause excess pressure and lead to sealing failures. Furthermore, consider the operating environment; if the bearings are exposed to dust or moisture, implementing protective seals or covers can help prolong their durability. By adhering to these maintenance tips, you can significantly enhance the efficiency and reliability of your pillow block bearings.

Related Posts

-

Exploring Split Pillow Block Bearings at the 138th Canton Fair 2025: Industry Insights and Trends

-

How to Choose the Right Cast Steel Block Bearing for Your Industrial Needs

-

Understanding the Role of Small Pillow Block Bearings in Everyday Machinery

-

Exploring the Advantages of Self Aligning Pillow Block Bearings in Modern Machinery

-

10 Essential Tips for Choosing Small Pillow Block Bearings for Your Projects

-

Why Choose Rolling Bearings for Enhanced Performance and Longevity in Machinery?