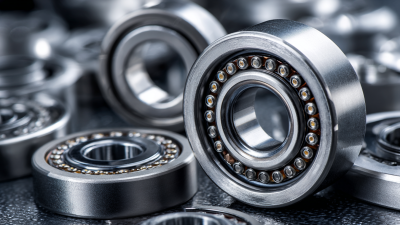

Exploring Innovations in Bearing Factory Automation: A Guide for Modern Manufacturing

In the rapidly evolving landscape of modern manufacturing, the need for advanced automation in Bearing Factory settings has never been more pressing. According to a report by MarketResearchFuture, the global bearing market is projected to reach approximately $90 billion by 2024, driven by increasing demand for high-performance and efficient machinery across various industries. The integration of innovative technologies such as IoT, AI, and robotics into Bearing Factory operations is essential for enhancing productivity, reducing operational costs, and maintaining competitive advantage. Moreover, a survey published by McKinsey highlights that manufacturers who embrace automation can improve their productivity by up to 30%. This guide delves into the latest innovations in Bearing Factory automation, offering insights and strategies for manufacturers aiming to optimize their processes and elevate their operational capabilities in this dynamic market.

Understanding the Fundamentals of Factory Automation in Bearing Manufacturing

Factory automation in the bearing manufacturing sector is pivotal for enhancing productivity and maintaining competitive edge. The fundamentals of factory automation encompass several key components: robotics, Internet of Things (IoT), and advanced manufacturing technologies that work together to optimize operations. According to a report by MarketsandMarkets, the global factory automation market is projected to grow from $166.0 billion in 2021 to $296.7 billion by 2026, reflecting a compound annual growth rate (CAGR) of 12.2%. This growth is largely attributed to the increasing demand for automation solutions that can deliver higher efficiency and lower production costs.

Factory automation in the bearing manufacturing sector is pivotal for enhancing productivity and maintaining competitive edge. The fundamentals of factory automation encompass several key components: robotics, Internet of Things (IoT), and advanced manufacturing technologies that work together to optimize operations. According to a report by MarketsandMarkets, the global factory automation market is projected to grow from $166.0 billion in 2021 to $296.7 billion by 2026, reflecting a compound annual growth rate (CAGR) of 12.2%. This growth is largely attributed to the increasing demand for automation solutions that can deliver higher efficiency and lower production costs.

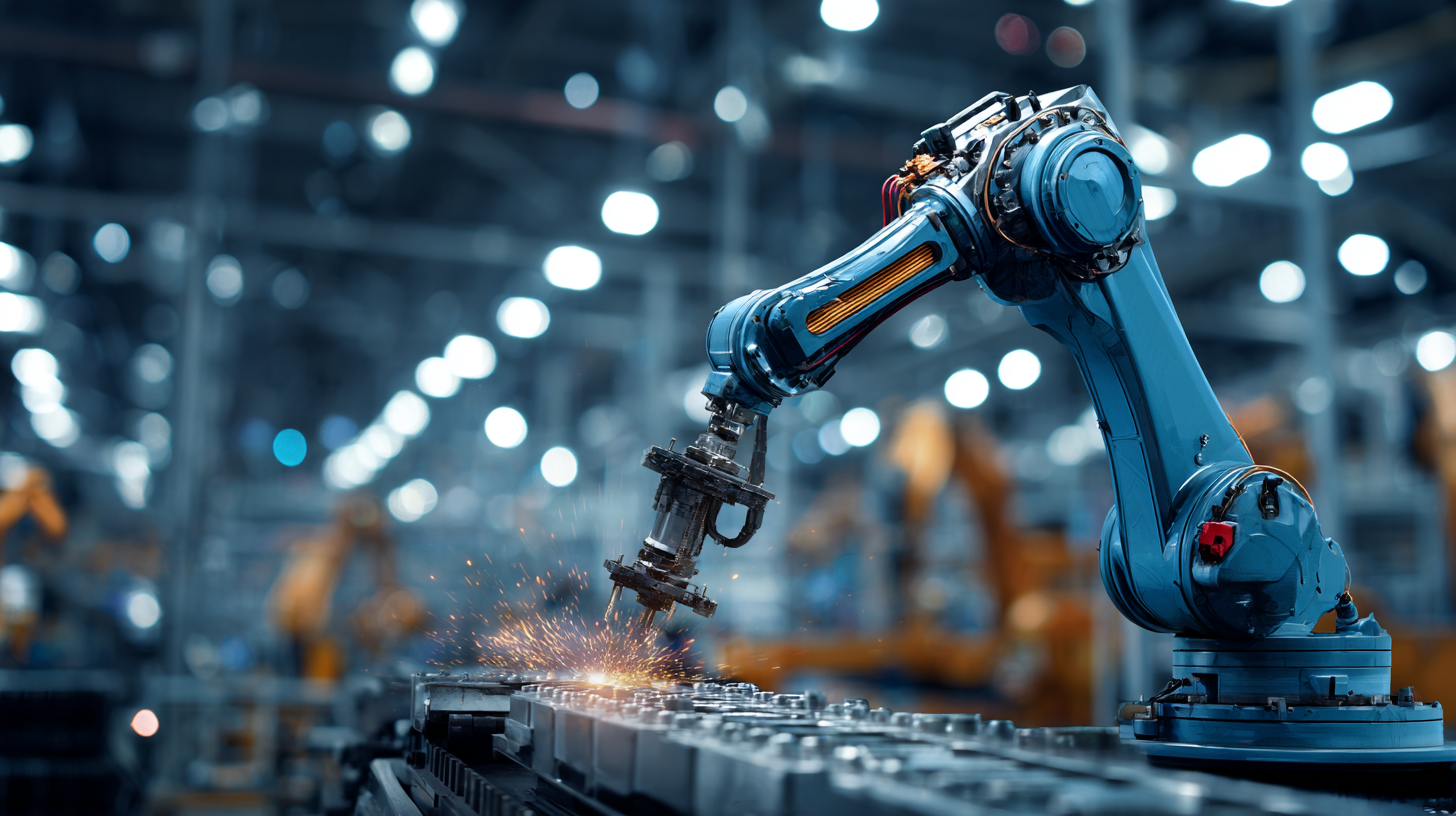

One of the significant advancements in bearing manufacturing is the utilization of automated guided vehicles (AGVs) and robotic arms, which streamline the assembly process and minimize human error. In a study published by the International Federation of Robotics, it was noted that the density of industrial robots in manufacturing has escalated to 113 robots per 10,000 employees, indicating a robust shift towards automation. Furthermore, the integration of IoT enables real-time data monitoring and predictive maintenance, allowing manufacturers to proactively address machinery issues and enhance overall equipment effectiveness (OEE). As these innovations reshape the landscape of bearing manufacturing, understanding and implementing these automation fundamentals is crucial for modern manufacturers striving for excellence.

Identifying Key Technologies Driving Bearing Factory Innovations

The modern manufacturing landscape is increasingly defined by technological innovations that enhance factory automation, particularly in specialized sectors like bearing manufacturing. Key technologies driving these innovations include advanced robotics, artificial intelligence, and the Internet of Things (IoT). These technologies enable seamless integration of automated processes within the manufacturing workflow, significantly improving efficiency and quality in production. With automation, bearing factories can achieve higher precision and consistency while also reducing operational costs.

In recent developments, industry leaders are focusing on autonomous solutions that not only improve throughput but also enhance product adaptability. For example, the push towards autonomous systems has been emphasized in recent speeches highlighting the importance of maintaining a robust manufacturing sector as an economic backbone. Engagement with specialists through training programs is becoming a norm, ensuring that engineers and technicians are well-versed in cutting-edge technologies. This strategic focus on innovation is crucial as the industry seeks to maintain competitive advantages in both domestic and global markets, ultimately driving sustainable growth in the manufacturing sector.

Evaluating the Benefits of Automation in Bearing Production Efficiency

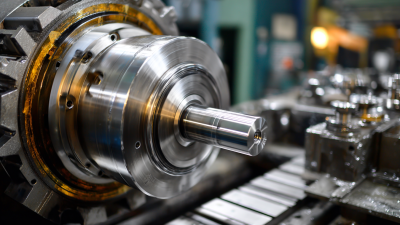

The integration of automation in bearing production significantly enhances manufacturing efficiency by streamlining processes and reducing operational costs. By employing advanced technologies such as robotics and artificial intelligence, factories can achieve higher precision in producing bearings, leading to lower defect rates. These innovations allow for continuous production cycles, which not only accelerates output but also ensures consistent quality in the finished products. As a result, manufacturers can respond swiftly to market demands while maintaining competitiveness.

Moreover, automation provides valuable data analytics, enabling manufacturers to monitor and optimize their processes in real time. This ability to track performance metrics and identify bottlenecks fosters a culture of continuous improvement. By leveraging these insights, production lines can be adjusted proactively, minimizing downtime and waste. The cumulative effect of these advancements is a more agile manufacturing environment, capable of adapting to the evolving needs of the market while maximizing resource utilization.

Implementing Smart Robotics for Enhanced Manufacturing Precision

In today's fast-paced manufacturing environment, the integration of smart robotics is pivotal for enhancing precision in bearing factories. These advanced robotic systems not only automate repetitive tasks but also leverage artificial intelligence to adapt to varying operational demands. By implementing smart robots, manufacturers can achieve remarkable improvements in production accuracy, reduce human error, and optimize the overall workflow.

Tips: When integrating smart robotics, consider starting with a pilot program that targets specific tasks. This allows you to evaluate the performance of robotics in real-world conditions and make necessary adjustments before a full-scale implementation.

Moreover, investing in training for your workforce to collaborate effectively with these smart systems will be essential. Employees should understand how to monitor and maintain robotic tools to ensure smooth operations. This synergy between human skills and robotic precision can lead to unprecedented productivity levels in manufacturing processes.

Tips: Foster a culture of continuous learning to keep your team updated on evolving technologies and best practices. Regular workshops and simulations can help bridge the gap between human expertise and robotic efficiency, leading to a harmonious blend of capabilities on the factory floor.

Assessing Future Trends in Automation for the Bearing Industry

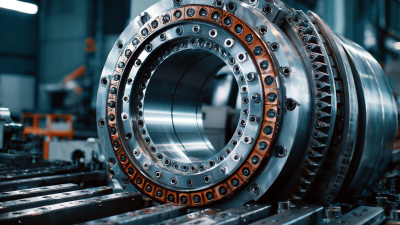

The future of automation in the bearing industry appears promising, with the global bearings market projected to surge from USD 50.16 billion in 2025 to an impressive USD 97.10 billion by the end of 2026. This rapid growth signals a shift towards more sophisticated manufacturing processes, driven by innovations in automation technologies. Manufacturers are increasingly adopting automation to enhance efficiency, reduce operational costs, and improve product quality. The integration of advanced robotics and artificial intelligence is facilitating precision in production, catering to the rising demand across various sectors, including automotive and renewable energy.

In the renewable energy domain, the Onshore Wind Turbine Bearing Market is expected to witness substantial growth, rising from USD 3003.7 million in 2025 to a projected USD 8376.4 million by 2035. This increase underscores the vital role bearings play in the efficiency and reliability of wind energy systems, further fueling the need for automated solutions in manufacturing. As the bearing industry navigates the evolving landscape shaped by technological advancements, the focus on automation will likely become a cornerstone for maintaining competitive advantage and meeting market demands.

Innovations in Bearing Factory Automation

This chart illustrates the current adoption rates of various innovations in bearing factory automation. Robotics and IoT integration show the highest adoption, indicating strong trends towards automation in modern manufacturing.

Related Posts

-

Exploring the Science Behind Bearing Manufacturing: Innovations in Bearing Factory Processes

-

Exploring Split Pillow Block Bearings at the 138th Canton Fair 2025: Industry Insights and Trends

-

Exploring Innovations in Bearing Factory Production: The Future of Machinery Efficiency

-

Exploring Innovations in Pillow Block Bearing Pullers at the 138th China Import and Export Fair 2025

-

How to Choose the Right Stainless Steel Bearing for Your Application

-

What You Need to Know About 25mm Pillow Block Bearing