10 Essential Tips for Choosing Small Pillow Block Bearings for Your Projects

When embarking on any engineering or mechanical project, one of the fundamental components that can significantly influence performance and efficiency is the selection of the right bearing. Among the numerous types available, Small Pillow Block Bearings stand out due to their versatility and compact design, making them an ideal choice for a wide range of applications. However, with the vast array of options on the market, selecting the most suitable bearing can be a daunting task for engineers and DIY enthusiasts alike.

This article aims to provide essential guidance to navigate the complexities of choosing Small Pillow Block Bearings for your projects. By understanding key factors such as load capacity, material quality, and dimensional specifications, you can ensure that the bearings you choose will meet the specific requirements of your application. Additionally, we will discuss common mistakes to avoid and offer practical tips that can save time and resources during the selection process. With these insights, you'll be equipped to make informed decisions that enhance the overall success of your engineering endeavors.

Key Considerations for Selecting the Right Small Pillow Block Bearings

When selecting small pillow block bearings for your projects, several key considerations come into play to ensure optimal performance and reliability. First and foremost, it is crucial to understand the load requirements of your application. Small pillow block bearings are designed to handle specific loads, and exceeding these limits can lead to premature failure. Assessing both dynamic and static loads can help determine the appropriate bearing capacity.

Another critical factor is the operating environment. Conditions such as temperature, humidity, and potential exposure to contaminants can significantly impact bearing performance. Select materials that can withstand these environmental factors, perhaps opting for sealed or shielded designs if contamination is a concern. Additionally, consider the lubrication requirements; proper lubrication not only reduces friction but also extends the lifespan of the bearings. By taking into account these essential aspects, you can ensure a wise selection that enhances the longevity and efficiency of your projects.

Comparison of Key Considerations for Choosing Small Pillow Block Bearings

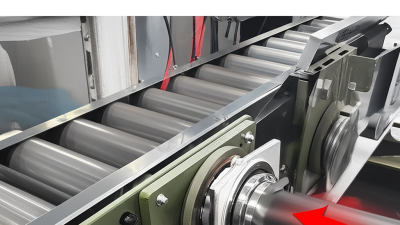

Understanding Load Capacity and Speed Ratings in Pillow Block Bearings

When selecting small pillow block bearings for your projects, understanding load capacity and speed ratings is crucial. Load capacity refers to the maximum load a bearing can support without failing. It is essential to consider both static and dynamic load ratings, which indicate the maximum load the bearing can handle when stationary and when in motion, respectively. Carefully evaluating the load requirements of your specific application will ensure that the bearing chosen can withstand the operational stresses and prevent premature wear or failure.

In addition to load capacity, speed ratings determine how fast a bearing can operate safely. Each pillow block bearing has a maximum RPM (revolutions per minute) rating which is vital in high-speed applications. Exceeding this rating can lead to increased friction, overheating, and ultimately, bearing failure. When choosing bearings, it's important to match the speed requirements of your project with those specifications to ensure reliability and longevity. Together, understanding load capacities and speed ratings will guide you in selecting the right pillow block bearings that can optimize performance and enhance the efficiency of your designs.

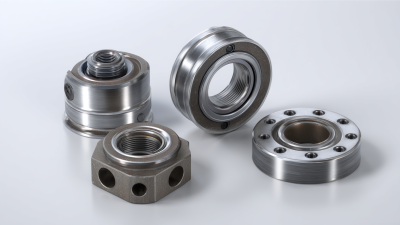

Material Choices: How to Choose the Best Bearing Surface for Your Needs

When selecting small pillow block bearings for your projects, one of the most critical aspects to consider is the materials used in the bearing surface. The right material choice can enhance performance, longevity, and overall efficiency. For applications that require resistance to wear and corrosion, materials like stainless steel or polyamide are ideal due to their durability and low friction properties.

When examining your material options, it's essential to think about the specific environment your bearings will be subjected to. For example, if your project involves high temperatures, bearing surfaces made of bronze or high-performance plastics may offer the best resilience. Always weigh the advantages and disadvantages of each material against your needs.

Tip: Always consider the load capacity and speed requirements of your project when choosing bearing materials. For lighter loads and lower speeds, plastic bearings can be sufficient and cost-effective. However, for heavy-duty applications, steel bearings are typically preferred due to their superior strength. Taking the time to evaluate these material options can help you make informed decisions for your specific applications.

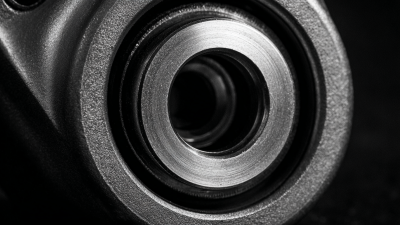

Identifying Appropriate Sealing Options for Enhanced Bearing Performance

When selecting small pillow block bearings, one critical aspect that often gets overlooked is the sealing options available. The appropriate sealing type can significantly impact the bearing's performance, longevity, and reliability. According to a report by the Global Bearing Market Research, nearly 40% of bearing failures are attributed to contamination due to inadequate sealing. Therefore, understanding the sealing mechanisms is vital for any project involving bearings.

There are several sealing options available, including rubber seals, metal shields, and labyrinth seals. Rubber seals provide excellent protection against dust and moisture while allowing for a low-friction operation. On the other hand, metal shields may offer a more durable solution in high-temperature applications, but they might not seal as effectively against fine particles.

Labyrinth seals, while not sealing off contaminants entirely, create a barrier that encourages contamination to exit rather than enter the bearing. Selecting the right seal not only enhances the bearing's operational efficiency but also ensures a longer service life, which is crucial in reducing maintenance costs. Integrating these considerations into your project planning can lead to significant improvements in overall performance.

Evaluating Cost vs. Quality: Maximizing Value in Bearing Selection

When selecting small pillow block bearings for your projects, it’s crucial to evaluate the balance between cost and quality. Low-cost bearings might seem attractive initially, but they can lead to significant long-term expenses due to frequent replacements and potential machinery downtime. Opting for higher-quality bearings often translates to improved performance, reliability, and a longer lifespan, which can ultimately save money over time by reducing maintenance and replacement costs.

Additionally, consider the application of your project when assessing value. Different environments and loads require specific bearing capabilities. Investing in quality bearings that are specified for your project’s unique conditions can prevent premature failure and enhance operational efficiency. By carefully weighing the cost against the quality and suitability of the bearings, you can make informed decisions that optimize both performance and budget, ensuring your projects achieve their intended goals without unexpected financial burdens.

10 Essential Tips for Choosing Small Pillow Block Bearings for Your Projects - Evaluating Cost vs. Quality: Maximizing Value in Bearing Selection

| Tip No. | Tip | Cost Factor | Quality Indicator | Value Rating |

|---|---|---|---|---|

| 1 | Assess Load Capacity | Medium | High | 4.5/5 |

| 2 | Consider Environmental Factors | Low | Medium | 4.0/5 |

| 3 | Evaluate Material Quality | High | High | 5.0/5 |

| 4 | Check Tolerance Specifications | Medium | High | 4.3/5 |

| 5 | Review the Manufacturer’s Reputation | N/A | High | 4.8/5 |

| 6 | Consider Installation Challenges | Low | Medium | 3.5/5 |

| 7 | Test for Vibration and Noise | High | High | 4.7/5 |

| 8 | Check Compatibility with Existing Components | Medium | Medium | 4.1/5 |

| 9 | Evaluate Lubrication Options | Medium | High | 4.4/5 |

| 10 | Analyze Long-Term Value vs. Initial Cost | High | High | 5.0/5 |

Related Posts

-

Exploring Split Pillow Block Bearings at the 138th Canton Fair 2025: Industry Insights and Trends

-

What You Need to Know About 25mm Pillow Block Bearing

-

Understanding the Role of Small Pillow Block Bearings in Everyday Machinery

-

Exploring the Benefits of Pillow Block Flange Bearings in Industrial Applications for Enhanced Performance

-

Exploring the Advantages of Self Aligning Pillow Block Bearings in Modern Machinery

-

How to Find the Best Pillow Block Bearings Near Me for Optimal Performance and Durability