10 Essential Tips for Choosing the Right Pillow Block Bearing 10mm

Choosing the right pillow block bearing 10mm can significantly impact your machinery's performance. Many factors affect this decision. It's crucial to consider the application and environment where the bearing will be used.

A pillow block bearing 10mm supports and aligns shafts. Selecting the wrong one can lead to premature wear or failure. Not all bearings come with the same specifications or materials. Check load ratings, speed limits, and environmental resistances.

Purchasing a pillow block bearing 10mm without adequate research can be costly. Some buyers overlook the importance of installation methods and proper maintenance. Mistakes can lead to inefficiencies. Reflecting on your choices can help you avoid future issues. Make informed decisions to enhance your equipment's longevity and efficiency.

Understanding Pillow Block Bearings: A Comprehensive Overview

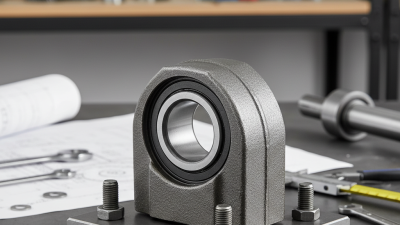

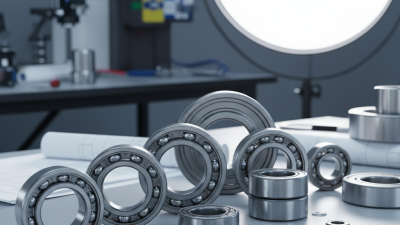

Pillow block bearings are crucial in various machinery. They support shafts and reduce friction effectively. Choosing the right type can be challenging, but understanding them helps make informed decisions. A pillow block bearing typically includes a mounted unit with a bearing inside. They come in various sizes and materials, often specified for unique applications.

When selecting a pillow block bearing, consider the environment. If it is exposed to dust or moisture, opt for a sealed option. The shaft diameter is essential too. A 10mm shaft requires specific dimensions and tolerances. Ensure the bearing fits snugly. A loose fit can lead to operational issues. It might save time initially, but neglecting size can lead to expensive repairs.

Installation and maintenance are often overlooked. Many assume they know how to install them correctly. Misalignment can occur easily. This may result in premature failure of the bearing. Regular checks are necessary to maintain performance. It’s not just about buying a product; it’s about ensuring longevity. Investing time in understanding the needs can pay off significantly.

Understanding Pillow Block Bearings: A Comprehensive Overview

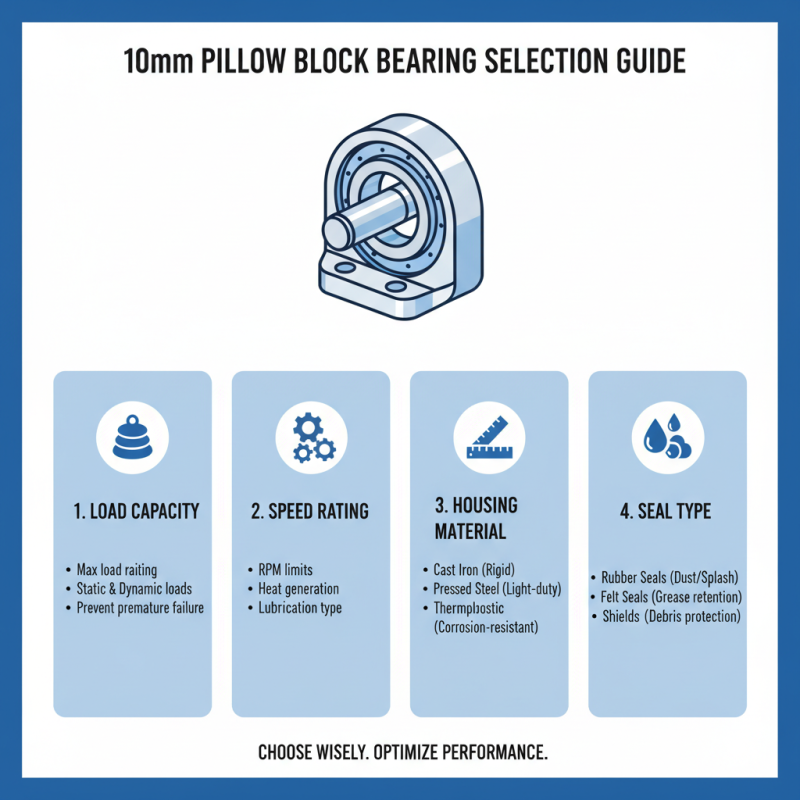

Key Specifications to Consider for 10mm Pillow Block Bearings

When selecting a 10mm pillow block bearing, it’s crucial to consider key specifications. Start with the load capacity. Each bearing has a specific load rating that determines the maximum load it can handle safely. If you choose a bearing with a lower capacity than needed, it may fail under pressure.

Another important specification is the speed rating. Bearings are designed for different RPM limits. Exceeding this limit can lead to premature wear. Additionally, think about the housing material. Metal housings are durable but heavier. Plastic housings are lighter but can lack strength.

Don’t overlook the lubrication type. Some bearings require manual lubrication, while others are sealed. A sealed bearing may save you time but could be harder to replace. It’s easy to focus only on the size and assume everything else fits. This can lead to oversight. Always double-check all specifications. It’s better to take extra time now than to deal with issues later.

Material Choices: Finding the Best Fit for Your Application

When selecting a pillow block bearing with a 10mm shaft, material choice plays a crucial role in performance and longevity. Common materials include steel, plastic, and aluminum.

Steel offers durability, ideal for heavy-duty applications. However, it can corrode if not properly maintained. Plastic, on the other hand, is lightweight and resistant to chemical exposure but may not handle heavy loads well.

Look closely at the operating environment. Materials have specific temperature and load limits. For example, aluminum is a good lightweight alternative but can deform under excessive stress. Consider if the bearing will face moisture. In wet environments, stainless steel could be a superior option.

Uplifting your bearing choice takes specific considerations. Talk with engineers about your application's demands. Take time to understand the conditions. This proactive approach allows for better material selection. Don't rush the process. A wrong choice might lead to frequent replacements, increasing costs in the long run. Always keep performance needs in mind. Adjust the selection process based on real-world needs. Keeping flexibility in your material options can yield the best results.

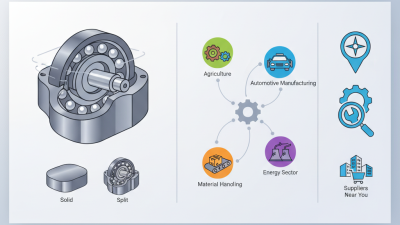

Mounting Options and Their Impact on Performance

Choosing the right pillow block bearing involves understanding various mounting options. These options significantly impact the performance and longevity of the bearing. According to recent industry reports, nearly 75% of bearing failures are attributed to improper mounting. This highlights the importance of selecting the right method for your specific application.

Different mounting styles include flanged, hinged, or base-mounted. Each style can affect alignment and load distribution. For instance, a flanged mount may provide better stability and reduce the chance of misalignment. However, if not correctly positioned, it can also lead to increase vibration. Studies show that incorrect mounting can reduce the lifespan of a bearing by over 50%. That's a substantial loss when performance is critical.

Often, users focus too much on the bearing itself rather than the mounting setup. This oversight can lead to increased maintenance costs and decreased efficiency. In some cases, operators have reported that minor adjustments in mounting can lead to significant performance improvements. It’s essential to continually evaluate your choices and adapt based on feedback and performance data.

10 Essential Tips for Choosing the Right Pillow Block Bearing 10mm - Mounting Options and Their Impact on Performance

| Tip Number | Mounting Option | Impact on Performance | Suitable Applications |

|---|---|---|---|

| 1 | With Base Plate | Stable installation, minimizes vibration | Industrial machinery |

| 2 | Flanged | Allows for compact space-saving configurations | Robotics and automation systems |

| 3 | Split Housing | Easier bearing replacement and maintenance | Heavy-duty applications |

| 4 | No Base | Lightweight, ideal for portable setups | Small machines and portable equipment |

| 5 | Belt Drive Compatible | Enables higher torque applications | Conveyors and processing equipment |

| 6 | Bearing Mounted | Direct mounting for increased efficiency | High-speed applications |

| 7 | Adjustable | Allows tension and alignment adjustments | Dynamic systems requiring frequent maintenance |

| 8 | Sealed Type | Enhanced protection against contaminants | Food processing and cleanroom environments |

| 9 | Self-Aligning | Compensates for shaft misalignment | Applications with thermal expansion |

| 10 | Heavy-Duty | Designed for high-load conditions | Mining and construction equipment |

Maintenance Tips for Longevity of Pillow Block Bearings

Proper maintenance of pillow block bearings is essential for their longevity. Regular inspection is key to spot any signs of wear or damage early. Look for leaks or unusual sounds. These early indicators can save you from more significant issues later. Lubrication is another critical factor. Ensure the bearings are properly greased to reduce friction and prevent overheating. Using the correct lubricant type can make a big difference.

Keep the surrounding area clean. Dust and debris can lead to premature failure. Make it a habit to clean the exterior regularly. Contamination may find its way inside, leading to rust or corrosion. Check alignment during installation as well. Misaligned bearings can cause uneven wear. If you notice vibration, it could be a sign of misalignment that requires immediate attention. Addressing these matters promptly can improve the bearing's performance.

Remember, monitoring performance is crucial. Set up a schedule for routine checks. It is easy to overlook this aspect when everything seems fine. However, neglect can lead to unexpected breakdowns. A little effort can go a long way in maintaining your pillow block bearings. Don't take maintenance for granted; it is a continuous process that pays off in durability.

Related Posts

-

20mm Pillow Block Bearing Best Applications and Benefits?

-

How to Choose the Right 25mm Pillow Block Bearing for Your Project?

-

10 Essential Tips for Choosing China Bearing in Your Projects?

-

Exploring the Science Behind Bearing Manufacturing: Innovations in Bearing Factory Processes

-

Understanding Pillow Block Bearings: Types and Where to Find Them Near Me

-

What is a Stainless Steel Bearing? A Comprehensive Guide to Its Types and Uses