10 Essential Tips for Choosing China Bearing in Your Projects?

Choosing the right China Bearing for your projects can be challenging. This decision significantly impacts performance and durability. According to industry expert Dr. Wei Zhang, "Selecting high-quality bearings is crucial for operational success." Without the right bearings, even the best machinery can falter.

When assessing China Bearings, consider manufacturer reputation and product specifications. Not all suppliers offer the same quality. Look for certifications and test results. Each detail matters, as even small discrepancies can lead to larger issues. It's worth digging deeper into the supplier's background.

Many projects overlook the importance of compatibility. A bearing that fits one application might not work in another. Be sure to evaluate your specific requirements thoroughly. Remember, not every China Bearing will meet your standards. Reflect on your choices, as the right selection can make a significant difference.

Understanding the Importance of Quality Bearings in Your Projects

When selecting bearings for your projects, understanding their quality is crucial. Quality bearings affect efficiency, reliability, and safety. According to a report by Research and Markets, the global bearings market is projected to reach over $100 billion by 2025. This underscores their significant role in various industries, from automotive to manufacturing. High-quality bearings reduce downtime and maintenance costs, making them a smart investment.

Tip: Evaluate suppliers meticulously. Check their certifications and manufacturing standards. The right supplier can ensure you get durable and reliable products.

Bearing failure can lead to costly delays. Often, the issue stems from poor-quality materials or wrong specifications. A study indicated that 20% of downtime in factories is linked to bearing issues. It's vital to consider the environment where the bearing will operate. For example, high temperatures may require specific materials that ensure longevity.

Tip: Always consider the load requirements of your application. Overestimating can lead to premature failure, while underestimating may compromise safety.

Invest time in thorough research before making a decision. The right bearing can greatly enhance the performance of your equipment. However, rushing can lead to mistakes that affect the overall success of your project.

Key Factors to Consider When Selecting Bearings from China

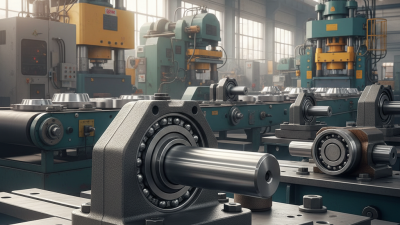

When selecting bearings from China, the manufacturing process is crucial. Understanding how bearings are produced can impact their quality and reliability. Look for manufacturers that use advanced technology and adhere to strict quality standards. The use of modern machinery often leads to better precision. Precision affects lifespan and performance in your project.

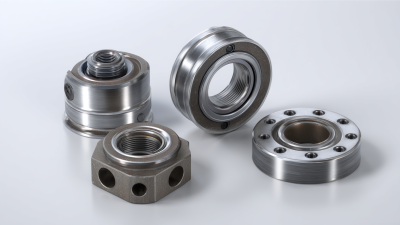

Material selection is another key factor. Look for high-grade materials that can withstand wear and tear. Cheap materials often lead to frequent replacements. This can result in additional costs and delays in your project. Speak with suppliers about their sourcing methods and material certifications.

Another important aspect is communication. Clear communication can prevent misunderstandings. Work with suppliers who respond promptly and provide detailed information. A supplier’s willingness to answer questions reflects their reliability. Sometimes, hasty decisions lead to subpar choices. Take time to evaluate multiple options before settling. Your project's success may depend on these choices.

Evaluating Manufacturers: Quality Control and Certification Standards

When selecting bearings from Chinese manufacturers, quality control is paramount. Various studies indicate that up to 40% of manufacturers lack adequate quality testing procedures. In an industry where precision is crucial, this is alarming. Ensure that potential suppliers have robust quality assurance systems in place. Look for manufacturers with ISO 9001 certification, which indicates adherence to international quality standards. This certification alone reduces risks significantly.

Moreover, it’s essential to review the specific testing protocols employed by manufacturers. Do they perform fatigue tests? How do they handle dimensional accuracy checks? Data from industry reports highlight that bearings with detailed inspection processes can exhibit performance improvements up to 30%. However, a lack of transparency in testing practices can lead to inconsistent product quality. Pay close attention to these details during assessment.

User feedback is also a crucial metric. Engage with users who have experience with different suppliers. Gather insights on product longevity and failure rates. Market analysis indicates that even suppliers with great certifications may not always deliver durable products. Your project’s success depends heavily on these evaluations. Thus, a thorough approach in evaluating suppliers in terms of quality control can yield better outcomes in the long run.

Evaluating China Bearing Manufacturers: Quality Control and Certification Standards

This chart presents the distribution of manufacturers certified under various quality control and certification standards in the China bearing industry. The data indicates that ISO 9001 has the highest number of certified manufacturers, reflecting its wide acceptance and importance in maintaining quality.

Cost vs. Quality: Finding the Right Balance for Your Project Needs

When selecting bearings for your project, balancing cost and quality is critical. Many may assume that cheaper options will suffice. However, lower prices often lead to compromised quality. Poor bearings can result in premature failure. This could lead to longer downtimes and costly replacements. It's important to weigh the risks carefully.

Consider the specific requirements of your project. What load will the bearings endure? How fast will they operate? Sometimes, spending a little extra can yield better performance. Conversely, overspending on unnecessary features can also be wasteful. It’s essential to align the bearing choice with the project's demands without straying into luxury options.

Reflect on your past experiences. Have you chosen price over quality? What were the consequences? Such reflections can guide future choices. Seek feedback from colleagues and experts to gain insights. Quality may seem subjective, but thorough evaluation can highlight significant differences. Ultimately, aim for optimal performance without draining your budget.

Logistics and Supply Chain Considerations for Sourcing Bearings in China

When sourcing bearings in China, logistics plays a pivotal role. Beyond selecting the right product, you need to consider shipping times and costs. Not all suppliers are located near major ports. Some are inland, leading to potential delays. Miscommunication can happen, especially if your supplier is not familiar with your required shipping terms.

Supply chain management is equally important. Understand the flow of materials and components. There might be disruptions due to national holidays or local regulations. Be aware that lead times can fluctuate. You must remain flexible and prepared for unexpected changes. Having backup suppliers can ease pressure during critical phases.

When evaluating costs, factor in hidden fees related to customs and tariffs. Sometimes, the lowest price doesn’t mean the best overall deal. Consider the quality and reliability of suppliers. A cheaper product may not always meet your standards. Reflecting on these aspects can lead to more effective decision-making in your projects.

Related Posts

-

Top 10 Heavy Duty Pillow Block Bearings for Maximum Performance

-

Why Choose Pillow Block Flange Bearings for Your Industrial Applications

-

Digital Guide to the Best Pillow Block Bearing Types for Your Projects

-

How to Find the Best Pillow Block Bearings Near Me for Optimal Performance and Durability

-

Exploring Innovations in Pillow Block Bearing Pullers at the 138th China Import and Export Fair 2025

-

Exploring the Advantages of Self Aligning Pillow Block Bearings in Modern Machinery