Digital Guide to the Best Pillow Block Bearing Types for Your Projects

In modern engineering and machinery, the selection of the right components is crucial for the efficiency and longevity of any project. One such vital component is the pillow block bearing, which plays a significant role in supporting rotating shafts and managing loads. Understanding the various Pillow Block Bearing Types available can greatly enhance the design and functionality of mechanical systems. This digital guide aims to provide an in-depth exploration of these types, catering to engineers, designers, and enthusiasts looking to optimize their projects.

By delving into the characteristics, advantages, and specific applications of different pillow block bearing types, readers will gain valuable insights necessary for making informed decisions. The guide will cover essential factors such as load capacity, material selection, and installation requirements, ensuring that each type's unique properties are thoroughly understood. As we navigate through the complexities of pillow block bearings, you'll be equipped with the knowledge to choose the ideal components for your mechanical and engineering endeavors, ultimately leading to improved performance and reliability in your projects.

Understanding the Functionality of Pillow Block Bearings

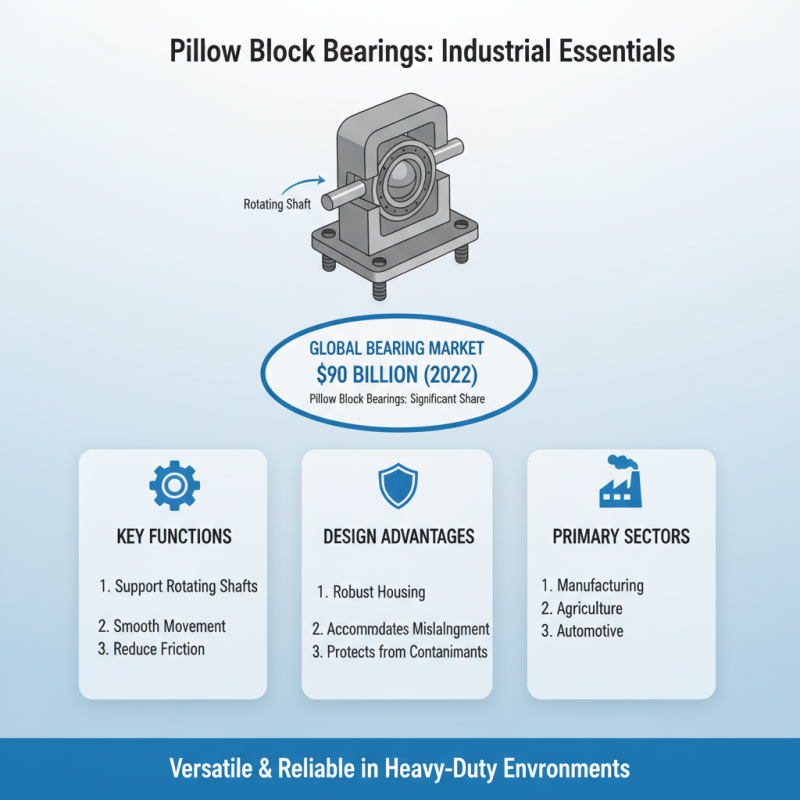

Pillow block bearings play a crucial role in various industrial applications by supporting rotating shafts, facilitating smooth movement, and reducing friction. Their design incorporates a bearing mounted in a robust housing, which is secured to a supporting structure. According to industry reports, the global bearing market was valued at approximately $90 billion in 2022, with pillow block bearings accounting for a significant share due to their versatility and reliability in heavy-duty environments. Their ability to absorb misalignments, accommodate shaft movement, and protect against contaminants makes them indispensable in sectors such as manufacturing, agriculture, and automotive.

Understanding the functionality of pillow block bearings is essential for optimizing project outcomes. They are engineered to provide not just support but also to enhance the operational efficiency of equipment. For instance, data from recent analysis indicates that using high-quality pillow block bearings can improve machine lifespan by up to 25% compared to standard options. This enhancement is largely attributed to reduced wear and tear and improved load distribution. As industries increasingly prioritize maintenance cost reduction and operational performance, the strategic selection and application of pillow block bearings become paramount in engineering solutions tailored for specific challenges.

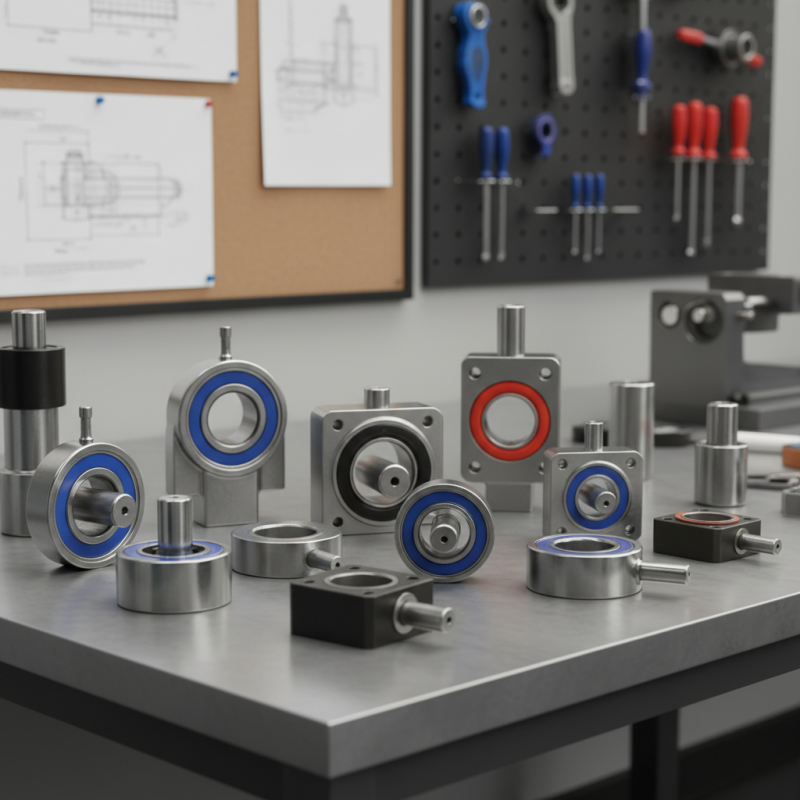

Common Types of Pillow Block Bearings and Their Applications

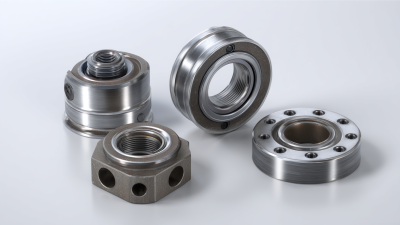

Pillow block bearings are essential components in various mechanical systems, allowing for smooth rotation and support of shafts. Among the common types, two of the most prevalent include the cast iron pillow block bearing and the thermoplastic pillow block bearing. Cast iron bearings are known for their durability and high load capacity, making them suitable for heavy-duty applications in industries such as mining and manufacturing. In contrast, thermoplastic bearings offer resistance to corrosion and are typically utilized in environments where moisture or chemicals may be present, such as in food processing and agricultural equipment.

When selecting a pillow block bearing, it is crucial to consider the operating conditions and specific application requirements. According to a report by the National Association of Manufacturers, approximately 30% of machinery failures can be attributed to bearing issues. Therefore, choosing the right type can significantly enhance equipment longevity and efficiency. For projects with varying temperature changes, self-aligning pillow block bearings may be advantageous due to their ability to accommodate misalignment.

**Tips:** Ensure you review the material compatibility and load ratings as per the application requirements. Conduct regular maintenance checks on pillow block bearings to avoid unexpected downtimes. Utilizing proper lubrication techniques can not only enhance performance but also extend the lifespan of the bearings, ensuring your projects run smoothly.

Digital Guide to the Best Pillow Block Bearing Types for Your Projects

| Bearing Type | Shaft Diameter (mm) | Load Capacity (kg) | Max Speed (RPM) | Common Applications |

|---|---|---|---|---|

| YZU Series | 20 | 1500 | 3000 | Conveyor Systems |

| HPB Series | 30 | 2500 | 2500 | Agricultural Machinery |

| MNB Series | 40 | 3500 | 2000 | Textile Processing Equipment |

| LTR Series | 50 | 5000 | 1500 | Marine Applications |

| CBB Series | 60 | 4500 | 1200 | Construction Machinery |

Factors to Consider When Selecting Pillow Block Bearings

When selecting pillow block bearings for your projects, several key factors must be evaluated to ensure optimal performance and longevity. First and foremost, the load capacity of the bearing should be considered. Knowing the static and dynamic loads that will act on the bearing is crucial in choosing one that can withstand these forces without failure. Additionally, understanding the operating environment—such as temperature, humidity, and potential exposure to corrosive substances—will help determine the right material and design for your application.

Another important aspect to consider is the bearing alignment. Proper alignment can significantly reduce wear and prevent premature failure. This means evaluating the installation process and surrounding components, ensuring that the shaft is precisely aligned with the bearing. Moreover, maintenance requirements should not be overlooked; some pillow block bearings may require regular lubrication or inspections to maintain their performance. Therefore, it’s essential to choose bearings that can accommodate your maintenance capabilities while providing a balance between durability and ease of care.

Digital Guide to the Best Pillow Block Bearing Types for Your Projects

This chart illustrates the load capacity of different types of pillow block bearings commonly used in various engineering projects. Understanding the load capacities can help in selecting the right bearing type for your specific applications.

Maintenance Tips for Prolonging Pillow Block Bearing Lifespan

Maintaining pillow block bearings is crucial for optimizing their performance and extending their service life. According to a report by the National Lubricating Grease Institute, improper maintenance can reduce bearing lifespan by up to 50%. Regular inspection and lubrication are key practices that can significantly mitigate wear and tear. It’s essential to select the right lubricant, as different applications require specific types of grease with varying viscosity and additive properties to provide optimal protection against corrosion and friction.

In addition to lubrication, keeping bearings clean is vital. Contaminants such as dust and debris can lead to premature failure, so implementing a routine cleaning schedule can help maintain performance. The American Society of Mechanical Engineers (ASME) recommends that industries incorporate a claims management system to track maintenance schedules and bearing conditions, thereby minimizing unexpected downtimes. Furthermore, aligning pillow block bearings correctly will prevent misalignment-related issues, which can further compromise their integrity and operational efficiency. By adhering to these maintenance strategies, projects can ensure longer-lasting and more reliable bearing performance.

Comparative Analysis of Pillow Block Bearings vs. Other Bearing Types

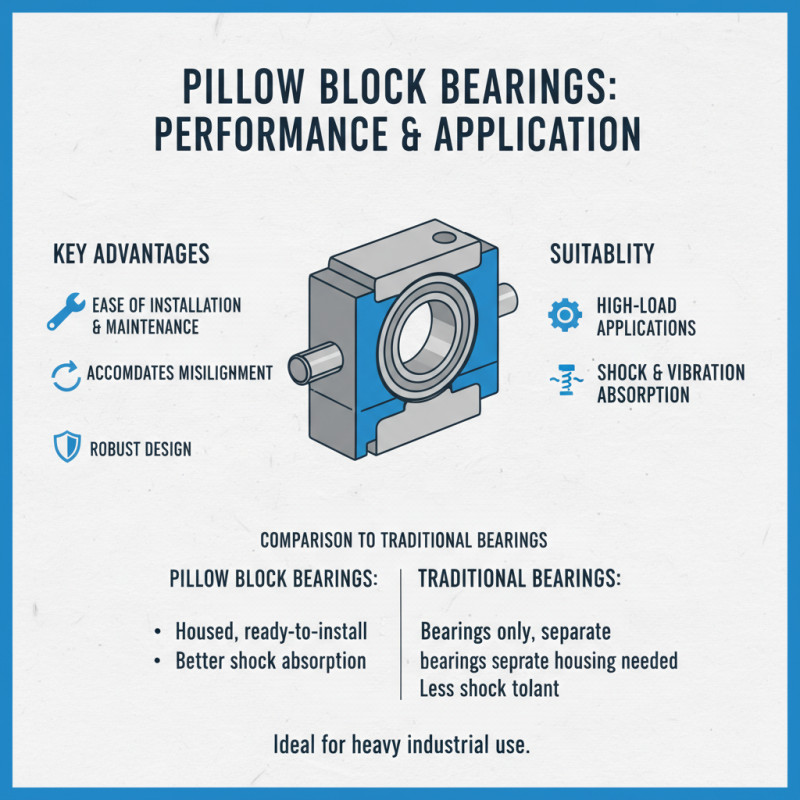

When evaluating the performance and application of pillow block bearings, it's essential to understand how they compare to other bearing types. Pillow block bearings are housed bearings that provide support and alignment. They offer several advantages, such as ease of installation, maintenance, and the ability to accommodate misalignment. Their robust design makes them particularly suitable for high-load applications, where they are often preferred over traditional bearings because they can absorb more shock and vibration.

In contrast, other bearing types, such as deep groove ball bearings or tapered roller bearings, have their own unique benefits depending on the application. For example, deep groove ball bearings are highly versatile and can handle both radial and axial loads, making them ideal for high-speed applications. Tapered roller bearings, on the other hand, excel in handling heavy axial loads in one direction and are commonly used in automotive applications. While pillow block bearings excel in heavy-duty and rugged environments, the choice of bearing type ultimately depends on specific project requirements, including load capacity, precision, and environmental conditions. By understanding these differences, engineers can make informed decisions to optimize their projects' performance.

Related Posts

-

Exploring Split Pillow Block Bearings at the 138th Canton Fair 2025: Industry Insights and Trends

-

Understanding the Role of Small Pillow Block Bearings in Everyday Machinery

-

Exploring the Advantages of Self Aligning Pillow Block Bearings in Modern Machinery

-

2025 Top 5 Harga Pillow Block Bearing: Key Features and Market Insights for Optimal Performance

-

10 Essential Tips for Choosing Small Pillow Block Bearings for Your Projects

-

Top 10 Heavy Duty Pillow Block Bearings for Maximum Performance