2026 How to Choose the Right Precision Bearing for Your Project?

In today's industrial landscape, selecting the right Precision Bearing is critical. The global Precision Bearing market is projected to reach $15 billion by 2026, driven by advancements in various industries such as automotive and aerospace. According to a recent report by Markets and Markets, a staggering 60% of production failures are linked to improper bearing selection.

Expert John Smith, a leading figure in the Precision Bearing industry, noted, “Choosing the right bearing is often overlooked, but it can make or break a project's success.” This underscores the gravity of making informed decisions when it comes to Precision Bearings.

Bearings play a vital role in machinery efficiency and longevity. Yet, many projects suffer from avoidable downtime. Factors such as load capacity, speed, and environmental conditions must be carefully considered. With a myriad of options available, it’s easy to feel overwhelmed. Improving the decision-making process is essential but often neglected. The right Precision Bearing can truly enhance performance, while the wrong choice can lead to costly setbacks.

Understanding Precision Bearings: Key Concepts and Applications

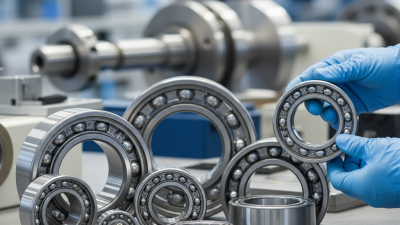

When selecting precision bearings, understanding their key concepts and applications is vital. Precision bearings are crucial in high-speed and high-performance systems. They reduce friction and improve efficiency. These bearings come in various types, including ball and roller bearings. Each type serves unique applications.

Here are some tips to consider. Always assess the load requirements. Determine if your application demands radial or axial loads. This decision impacts bearing choice significantly. Also, pay attention to environmental conditions. Dust, moisture, and temperature can affect performance. Choosing the right materials can mitigate these risks.

It's essential to reflect on your project's specific needs. Not every precision bearing will fit every application. Sometimes, a bearing may not perform as expected. Regular testing and monitoring are necessary. This process helps identify potential issues early on. Ignoring minor discrepancies can lead to larger failures later. Thus, thorough evaluation upfront is indispensable.

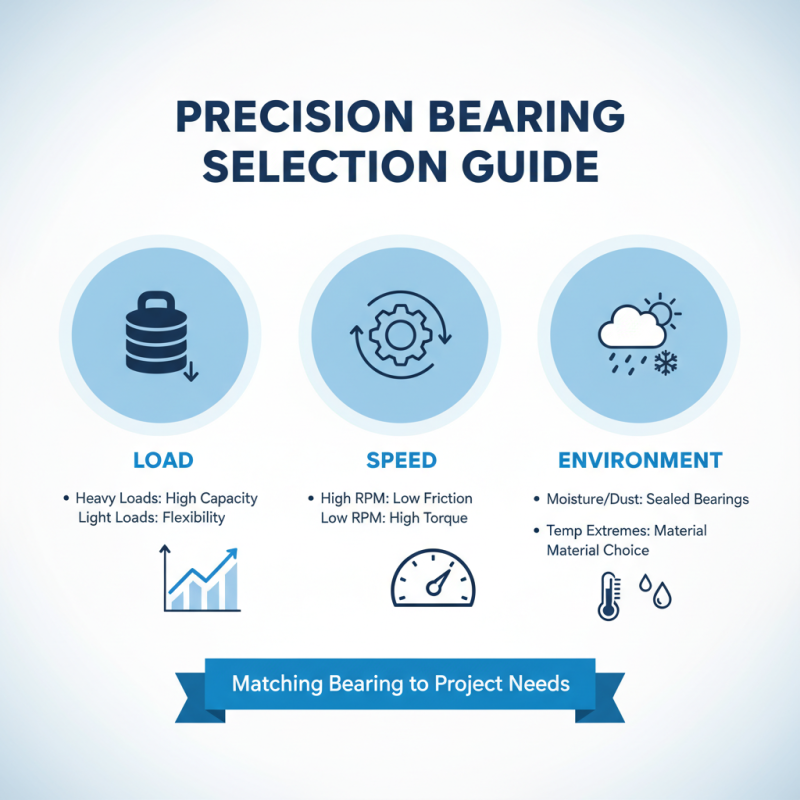

Identifying Project Requirements: Load, Speed, and Environmental Factors

Selecting the right precision bearing involves understanding specific project requirements. Load, speed, and environmental factors play significant roles. Knowing the load helps determine the bearing's capacity. For instance, heavy loads require bearings with higher load ratings. Light loads might allow for more flexibility in selection.

Speed is crucial as well. Bearings must withstand the operational speeds of your project. High-speed applications demand bearings with lower friction to minimize heat. Excessive heat can lead to failure, so be mindful of this aspect. Different designs cater to varying speed requirements.

**Tips:** Always check the manufacturer’s specifications for load limits and speed ratings. Consider the environment where the bearing will operate. Dust, moisture, and extreme temperatures can affect bearing performance. It’s good to evaluate the potential risks and their impacts on your choice. Don’t overlook the importance of proper lubrication; it can extend the bearing's lifespan significantly.

Types of Precision Bearings: An Overview of Options Available

When selecting precision bearings, understanding the types available is crucial. There are several common types, each suited for specific applications.

Ball bearings are widely used in various industries. They offer low friction and high-speed capabilities. Roller bearings, on the other hand, can handle heavier loads but are generally slower. Their cylindrical shape allows for better load distribution.

According to industry reports, the demand for angular contact bearings has grown by 14% over the past three years. These bearings excel in handling axial loads, making them ideal for high-speed applications. However, they may require more maintenance due to complex alignment needs.

Thrust bearings are another option; they perform well in applications involving axial forces. Their design allows them to withstand heavy loads but can be less efficient at high speeds.

Selecting the right bearing is often a balancing act. Each type comes with trade-offs that can impact performance.

For example, while ceramic bearings are known for their durability, they can be cost-prohibitive. Understanding the operating environment is essential. Factors like temperature, load, and speed can influence the choice. Missteps in this process can lead to equipment failure or inefficiency.

Thus, careful consideration is necessary for successful project outcomes.

Materials and Manufacturing Processes: Impact on Performance and Durability

When selecting precision bearings, materials and manufacturing processes play critical roles in performance and durability. Different materials lend distinct properties to bearings. For example, steel bearings are common due to their strength and load capacity. However, in corrosive environments, ceramic bearings can outperform steel. Understanding these materials is key. Each type has advantages and drawbacks.

Manufacturing processes also impact quality. Techniques like grinding and heat treatment can enhance precision. However, inconsistencies may arise in mass production. Some bearings may not meet the required specifications. Such issues can lead to premature wear and failure, affecting project outcomes. Attention to detail in these processes is essential for reliability.

An often-overlooked aspect is lubrication. Proper lubrication minimizes friction and heat generation. Yet, selecting the wrong lubricant can counteract even the best materials. This could lead to poor performance and short lifespan. Evaluating both materials and processes is necessary, but it's equally important to consider lubrication. Ideal solutions should address all these factors for optimal results.

Guidelines for Selection: Factors to Consider for Optimal Choice

Choosing the right precision bearing for your project requires careful consideration of several factors. The application type is crucial. Will it bear heavy loads or operate at high speeds? Each scenario demands different specifications. Temperature range is another important aspect. Bearings have limits, and exceeding them can shorten their lifespan. Know the environment your bearings will face—will it be dusty, wet, or oily?

Material selection plays a significant role in performance. For instance, stainless steel offers corrosion resistance but may not handle heavy loads as well as other materials. It's vital to balance durability and weight to fit your specific needs. Ensure you also consider tolerances. Tight tolerances can increase performance but lead to higher costs. Reflect on your project's budget and timeline because intricate requirements might lead to delays.

While researching options, be aware that not every choice will be perfect. Sometimes, you might find that a bearing looks great on paper but underperforms in real-world use. Iterating on your selection can offer insights for future projects. Keep an open mind and learn from each decision. Precision bearing selection is a journey filled with trial and error, leading you towards optimal results.

Related Posts

-

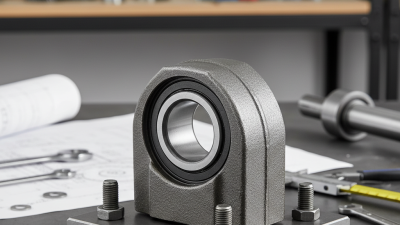

How to Choose the Right 25mm Pillow Block Bearing for Your Project?

-

The Innovative Future of Bearing Factories and Their Role in Modern Technology

-

Unlocking the Benefits of Self Aligning Pillow Block Bearings in Modern Machinery

-

Exploring Innovations in Pillow Block Bearing Pullers at the 138th China Import and Export Fair 2025

-

Exploring Split Pillow Block Bearings at the 138th Canton Fair 2025: Industry Insights and Trends

-

Why Choose Rolling Bearings for Enhanced Performance and Longevity in Machinery?