How to Choose the Right 25mm Pillow Block Bearing for Your Projects

In the world of mechanical engineering, choosing the right components is crucial for the success of any project. One such vital component is the 25mm Pillow Block Bearing, which plays a significant role in providing support and stability to rotating shafts in various applications. As industry expert Dr. John Reynolds points out, "Selecting the right pillow block bearing can make or break your project's efficiency and lifespan." This statement underscores the importance of understanding the specifications and requirements of your application when selecting a bearing.

When it comes to the 25mm Pillow Block Bearing, considerations such as load capacity, material type, and mounting options are paramount. These factors can significantly impact the performance and durability of the bearing in practical use. As you navigate through the myriad of choices available in the market, it’s essential to assess how the specific characteristics of the 25mm Pillow Block Bearing align with the demands of your project.

This article aims to guide you through the process of selecting the most suitable 25mm Pillow Block Bearing for your needs, ensuring that you make informed decisions that lead to successful outcomes in your engineering endeavors. Whether you are working on a small-scale project or a large industrial application, understanding the intricacies of pillow block bearings will enhance the reliability and efficiency of your designs.

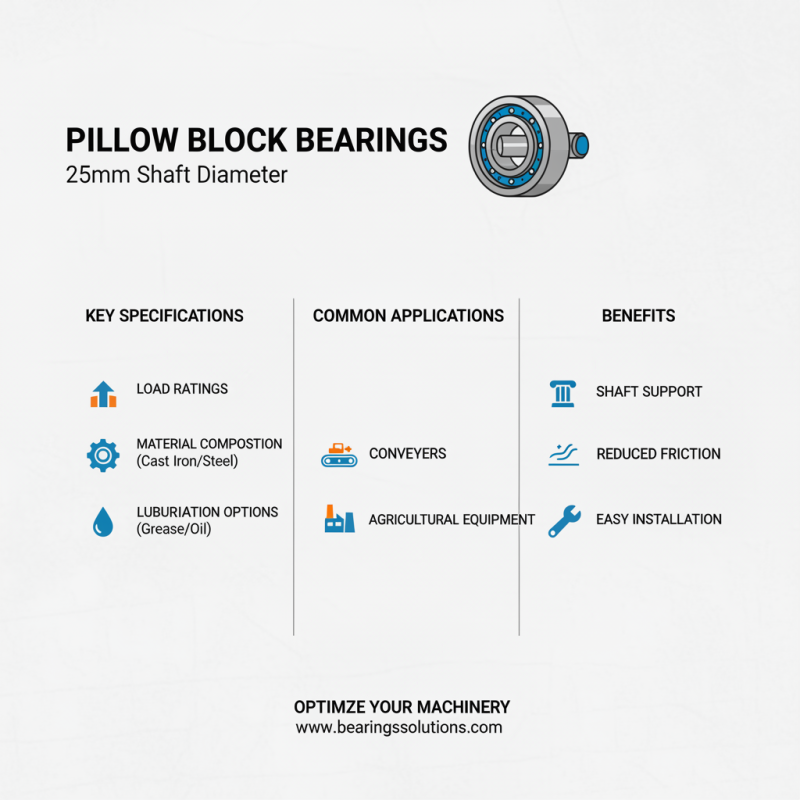

Understanding 25mm Pillow Block Bearings: Specifications and Applications

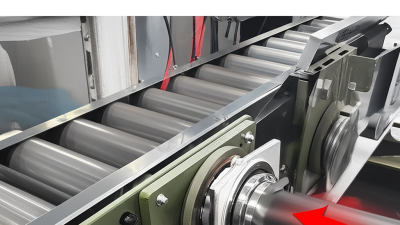

Pillow block bearings, particularly those with a 25mm shaft diameter, are essential components in various mechanical applications. These bearings are designed to support rotating shafts and are commonly found in machinery like conveyors, agricultural equipment, and industrial machinery. Understanding their specifications, such as load ratings, material composition, and lubrication options, is crucial for selecting the right bearing that aligns with the demands of your project.

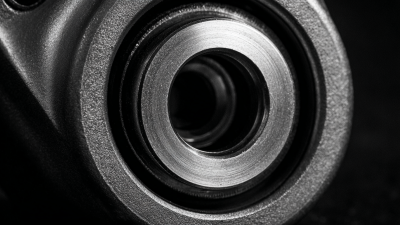

The primary specifications to consider when choosing a 25mm pillow block bearing include its dynamic and static load capacities, as these determine the bearing's ability to withstand applied forces during operation. Additionally, the bearing material—often made from cast iron, stainless steel, or thermoplastic—can affect the bearing's durability and resistance to environmental factors such as moisture and contaminants. Furthermore, features like sealed or open designs should be taken into account based on the operational environment, as they influence maintenance needs and overall performance.

Applications for 25mm pillow block bearings are diverse, ranging from light-duty tasks in DIY projects to more robust applications in commercial machinery. Their ability to accommodate misalignment and ease of installation makes them popular in settings that require reliable performance under variable conditions. Whether you are designing a new system or replacing worn-out components, understanding the specifications and applications of these bearings will ensure optimal functionality and longevity in your mechanical projects.

Key Factors to Consider When Selecting Pillow Block Bearings for Projects

When selecting the appropriate 25mm pillow block bearing for your projects, several key factors must be considered to ensure optimal performance and longevity. First and foremost, the load capacity is critical. According to recent industry reports, bearings with higher dynamic load ratings are increasingly favored in heavy machinery applications due to their enhanced durability and reduced failure rates. Evaluating the specific load type—whether it's radial, axial, or a combination—is essential for selecting a bearing that can handle the operational stresses of the intended application.

Additionally, the operating environment should not be overlooked. Bearings exposed to contaminants like dust, moisture, or extreme temperatures may require specialized sealing solutions or materials that can withstand corrosion and wear. A study by the Bearing Manufacturers Association highlighted that incorporating proper sealing can extend a bearing's lifespan by up to 50%, underscoring the importance of environmental considerations in your selection process. Lastly, alignment and mounting type are factors that directly affect bearing performance; improper alignment can lead to premature failure, making it imperative to choose the right mounting options based on your project's design specifications.

Comparative Analysis of Material Composition in Pillow Block Bearings

When selecting a 25mm pillow block bearing for various applications, an essential factor to consider is the material composition of the bearing itself. Pillow block bearings can be made from a variety of materials, including steel, stainless steel, and various polymers. Each material offers unique advantages and disadvantages that can significantly impact performance, durability, and cost.

For instance, steel bearings are known for their strength and load-bearing capabilities but may corrode in humid environments. Conversely, stainless steel offers enhanced corrosion resistance, making it suitable for applications in harsh conditions, though they may be more expensive.

Additionally, polymer bearings have gained popularity due to their lightweight characteristics and resistance to corrosion, making them ideal for applications in environments where lubrication is difficult. The choice of material also affects the bearing’s thermal conductivity, wear resistance, and overall lifespan.

Therefore, understanding the specific demands of the intended application is crucial when evaluating the material composition of pillow block bearings. By comparing these materials, one can ensure that the selected bearing not only meets operational needs but also contributes to the longevity and reliability of the machinery involved.

Load Ratings and Performance: Choosing the Right Bearing for Your Needs

When selecting a 25mm pillow block bearing, understanding load ratings and performance characteristics is crucial for ensuring optimal operation in your projects. Load ratings, which are typically expressed as dynamic and static load capacities, provide insight into how much weight the bearing can handle under different conditions. According to industry standards, a bearing's dynamic load rating is determined based on a standardized life expectancy of one million revolutions. For instance, standard specifications indicate that a pillow block bearing with a dynamic load rating of 10,000 N can safely support rotating loads in various applications without significant wear over time.

In addition to load ratings, it's also essential to consider the performance aspects such as speed and temperature limits. Many pillow block bearings are designed to operate efficiently at high speeds, with some models capable of exceeding 5,000 RPM. However, exceeding these limits can lead to premature failure. As highlighted in a recent publication by the International Journal of Engineering and Technology, proper lubrication and alignment play a significant role in enhancing these performance metrics. This same report notes that up to 80% of bearing failures can be traced back to misalignment or inadequate lubrication practices, underscoring the importance of incorporating quality bearings that meet specific operational demands for longevity and efficiency.

Load Ratings of 25mm Pillow Block Bearings

Installation Best Practices for Optimal Performance of Pillow Block Bearings

When installing 25mm pillow block bearings, adhering to best practices is crucial for ensuring optimal performance and longevity of the bearing system. According to the American Bearing Manufacturers Association (ABMA), improper installation can lead to premature bearing failure, resulting in significant downtime and increased maintenance costs. To mitigate these risks, it is essential to follow a systematic approach during installation.

Firstly, ensure that the mounting surface is clean, flat, and free of any debris that could affect alignment. Misalignment is one of the leading causes of bearing wear, with studies indicating that a mere 0.1-degree misalignment can reduce bearing life by up to 50%. Proper alignment techniques, such as using laser alignment tools, can drastically improve the reliability of pillow block bearings. Additionally, using the appropriate torque specifications when fastening the bearings is vital. Over-tightening can cause damage to the bearing housing, while under-tightening can lead to excessive play and vibration. Following manufacturer guidelines and consulting precision measurement standards ensures that the installation process adheres to industry benchmarks.

Furthermore, lubrication is an integral part of maintaining pillow block bearings. According to the International Organization for Standardization (ISO), bearings that are inadequately lubricated can experience friction losses of up to 90%, greatly affecting their efficiency. Regular lubrication intervals should be established based on operating conditions, load levels, and the environment to ensure that the bearings operate smoothly. Utilizing high-quality lubricants that suit the specific application can further enhance performance and extend service life. By following these best practices, operators can significantly improve the durability and functionality of their 25mm pillow block bearings, ultimately contributing to the overall success of their projects.

Related Posts

-

How to Find the Best Pillow Block Bearings Near Me for Optimal Performance and Durability

-

What You Need to Know About 25mm Pillow Block Bearing

-

Exploring the Benefits of Pillow Block Flange Bearings in Industrial Applications for Enhanced Performance

-

10 Essential Tips for Choosing Small Pillow Block Bearings for Your Projects

-

Top 10 Pillow Block Bearings Near Me for Optimal Performance and Value

-

Digital Guide to the Best Pillow Block Bearing Types for Your Projects