2026 How to Choose the Right Pillow Block Bearing Types for Your Needs?

Choosing the right Pillow Block Bearing Types can significantly impact your machinery's performance. According to industry expert John Smith, “Selecting the correct bearing type is crucial for efficiency.” Understanding the various Pillow Block Bearing Types is essential for optimizing equipment stability.

When considering Pillow Block Bearing Types, factors such as load capacity and environment matter greatly. Each type serves distinct purposes, and a wrong choice can lead to failures. It's critical to evaluate your specific needs and application nuances.

Moreover, common misconceptions about these bearings can lead to improper selections. For instance, many overlook maintenance requirements. Engaging an expert can mitigate risks associated with these choices. Remember, the right Pillow Block Bearing Type can enhance performance, but the wrong one may cause issues.

Understanding Pillow Block Bearings: Definition and Purpose

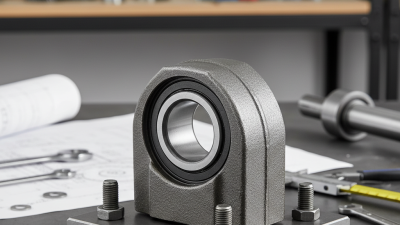

Pillow block bearings play a crucial role in various machinery and equipment. They act as a housing for the shaft and provide support. Understanding their definition is vital for selecting the right type.

These bearings are often made from materials like cast iron, which accounts for 40% of their market share, according to a recent industry report. They can handle high loads and rotating shafts. However, their design may not suit every application. It’s essential to assess requirements carefully.

Several types of pillow block bearings exist. Some are designed for high-speed applications, while others excel in heavy-duty environments. This diversity can lead to confusion. Not all options are perfect for every need. Testing is often necessary to find the best fit, as each application presents unique challenges.

2026 How to Choose the Right Pillow Block Bearing Types for Your Needs?

This chart illustrates the frequency of usage for different types of pillow block bearings. Steel bearings are the most commonly used, followed by stainless steel, while composite and plastic types have lower usage rates.

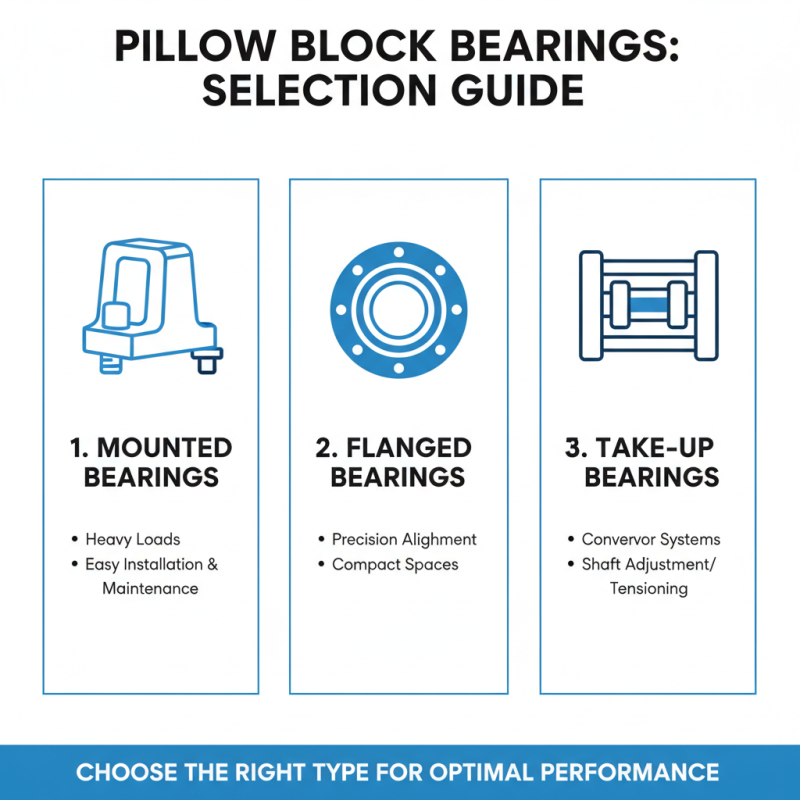

Types of Pillow Block Bearings: Key Differences and Applications

When selecting pillow block bearings, it's crucial to understand the different types available. Common types include mounted bearings, flanged bearings, and take-up bearings. Each type has specific applications that can significantly impact performance. For instance, mounted bearings are ideal for heavy loads and require less maintenance. Their design allows quick installation.

On the other hand, flanged bearings offer versatility. They are great for constrained spaces. These bearings can support radial loads efficiently. However, their installation can sometimes be tricky, leading to alignment issues if not done properly. Reflecting on your needs is key to making the right choice.

Take-up bearings are another option, often used for adjusting tension in conveyor systems. They provide flexibility in design but can be prone to wear over time. Knowing the working environment helps tailor your selection. Think about load capacity and environmental conditions. The right choice enhances performance, yet, poor selection can lead to increased downtime and costs.

Factors to Consider When Choosing Pillow Block Bearings

Choosing the right pillow block bearing can be challenging. Several factors influence the decision. Start by assessing the load requirements. How much weight will the bearing support? A heavier load demands more robust construction. Consider the environment as well. Are the bearings meant for a damp or dusty area? Environmental factors significantly affect bearing performance.

Another key factor is the type of shaft. Not all pillow block bearings fit every shaft type. Measure the shaft diameter accurately. This helps in selecting the appropriate bearing. Pay attention to lubrication needs too. Some bearings are self-lubricating, while others require regular maintenance. Neglecting this can lead to premature failure and unnecessary expenses.

Lastly, confirm the mounting options. Do you need a vertical or horizontal setup? The orientation can impact the bearing's efficiency. Finally, think about future needs. Will the application change? It’s wise to leave room for upgrades. Not every choice is straightforward. Reflect on these key points before making a decision.

Installation and Maintenance Tips for Pillow Block Bearings

Proper installation and maintenance of pillow block bearings is crucial for optimal performance. Start by ensuring the mounting surface is clean and flat. Misalignment is a common issue that can lead to premature failure. Take the time to adjust the position accurately. This step often gets overlooked, but it's vital for longevity.

When it comes to maintenance, regular inspections are essential. Check for signs of wear and tear, like noise or overheating. Lubrication is key; however, too much can cause issues just as too little can. Finding the right balance can feel tricky. Sometimes, a good practice is to apply a small amount, then reassess after some initial operation.

Remember, not every installation goes smoothly. Mistakes can happen, and addressing them early is important. If you notice performance issues, don’t hesitate to dismantle and inspect. It may take extra time, but it can prevent bigger problems down the line. Aim for precision and consistency to enhance the lifespan of your bearings.

Common Mistakes to Avoid When Selecting Pillow Block Bearings

When selecting pillow block bearings, many make common mistakes that can lead to inefficiencies. A report from the International Journal of Engineering analyzed failure rates in different bearing types. It showed that improper selection leads to a 30% increase in maintenance costs. Choosing the wrong size or mounting method can cause premature failures and increased downtime.

Focusing too much on price is another error. While cost is important, quality often matters more. In fact, a study by the Bearing Industry Group revealed that low-cost bearings fail up to 50% faster. This can be due to materials or design flaws that aren't immediately visible. Thus, evaluating performance specifications is crucial.

Ignoring environmental factors is a significant oversight. A bearing used in a high-temperature environment requires materials that can withstand these conditions. Reports indicate that 40% of premature failures are linked to unsuitable operating conditions. Proper classification of the operating environment will help in choosing the right material and design. Reflecting on these aspects can greatly improve the lifespan and reliability of your bearings.

Related Posts

-

2025 Top 5 Harga Pillow Block Bearing: Key Features and Market Insights for Optimal Performance

-

Top 10 Pillow Block Bearings Near Me for Optimal Performance and Value

-

Digital Guide to the Best Pillow Block Bearing Types for Your Projects

-

20mm Pillow Block Bearing Best Applications and Benefits?

-

How to Choose the Right 25mm Pillow Block Bearing for Your Project?

-

Mastering Mechanical Maintenance: The Essential Guide to Pillow Block Bearing Pullers for Every Workshop