How to Choose the Right 25mm Pillow Block Bearing for Your Project?

Selecting the right 25mm Pillow Block Bearing for your project can be challenging. Experts like John Smith, a leading engineer in motion control, emphasize, "The correct bearing choice can make or break your project." This statement highlights the critical nature of informed decisions in mechanical design.

A 25mm Pillow Block Bearing holds significant importance in various applications. It supports rotating shafts, ensuring smooth operation. However, not every bearing is created equal. You must consider load capacity, operating speed, and material. Often, individuals overlook these factors, leading to inefficient performance.

In the vast bearing market, the choices can be overwhelming. Many settle for the first option they find, risking project success. A thoughtful evaluation is essential. By reflecting on the specific needs of your application, you can avoid costly mistakes. Choosing a 25mm Pillow Block Bearing requires due diligence and careful consideration of all aspects involved.

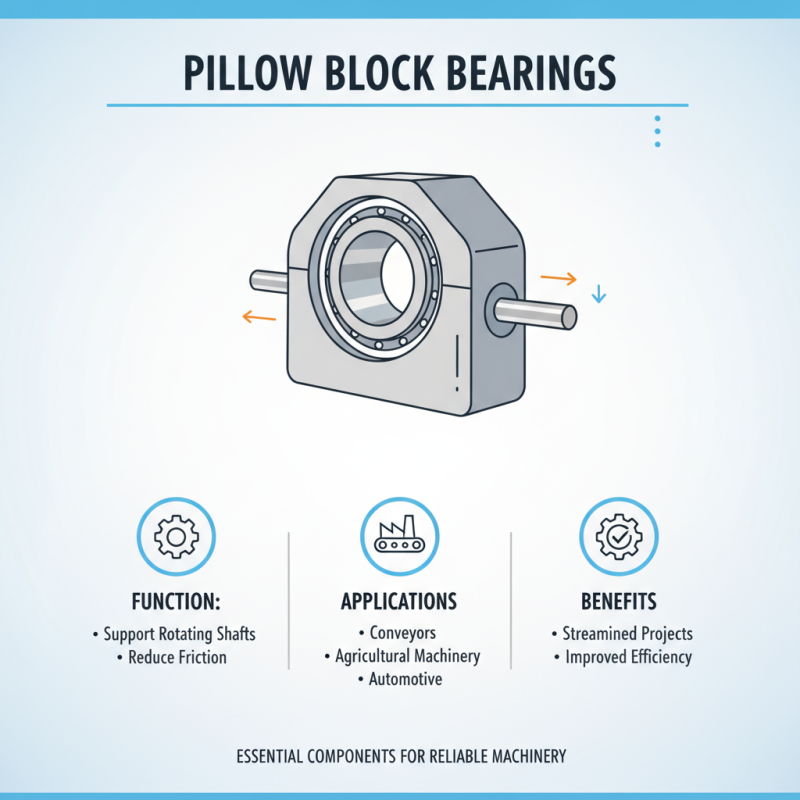

Understanding Pillow Block Bearings and Their Applications

Pillow block bearings are essential components in many machines. They support rotating shafts and reduce friction. Understanding their applications can streamline your project and improve efficiency. These bearings are often used in conveyors, agricultural machinery, and even in automotive applications.

Choosing the right pillow block bearing involves more than just size. You must consider the load capacity and environmental conditions. For example, if your project operates in a dusty environment, a bearing with dust seals may be necessary. Pay attention to the material as well. Some materials resist corrosion better than others.

Tips: Always check the shaft diameter and housing dimensions. Make sure they fit your design. Also, consider the rotation speed. High speeds can lead to overheating. Sometimes, you may need to adjust your design based on the bearing's specifications. Do your research to avoid costly mistakes.

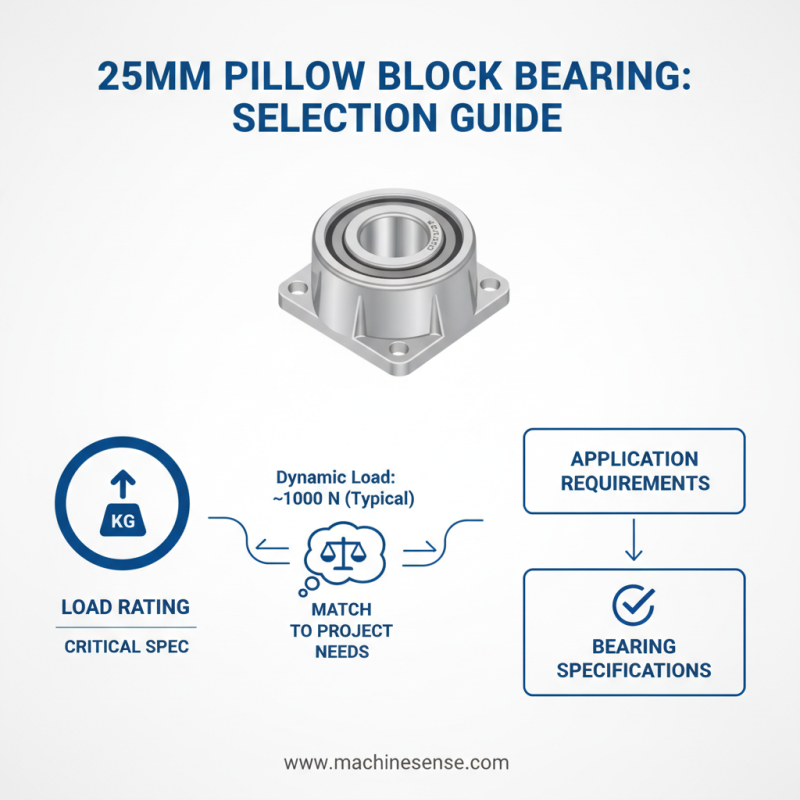

Key Specifications of 25mm Pillow Block Bearings to Consider

Choosing the right 25mm pillow block bearing involves understanding key specifications. One critical aspect is the load rating. Load ratings indicate how much weight the bearing can support. A typical 25mm pillow block bearing may have a dynamic load rating of around 1,000 N. However, specific applications may require different ratings. Always match the load capacity to your project's needs.

Another vital specification is the bearing material. Common materials include high-grade steel and composite materials. Steel bearings often offer better durability but can add weight. Conversely, composite materials are lighter but may wear faster under heavy loads. According to industry reports, the right material choice can enhance performance by up to 30%.

Additionally, consider the operating temperature range. Many bearings can operate between -20 to 100 degrees Celsius. Some specialized bearings can endure higher temperatures. Ignoring this may lead to premature failure. A study revealed that 15% of bearing failures occur due to temperature miscalculations. Understanding these details can prevent issues down the line.

Factors Influencing the Selection of the Right Bearing Material

When choosing a 25mm pillow block bearing, the material is crucial. Various materials offer distinct advantages and disadvantages. For example, steel is strong and durable. However, it can rust without proper coating. On the other hand, stainless steel resists corrosion but may be more expensive.

Another option is plastic. It is lightweight and can be cheaper. Yet, plastic may not handle high loads as well. Each material has its own impact on performance and longevity. It's essential to consider the environment where the bearing will be used.

Keep in mind that the wrong material could lead to failures. A bearing that fails can cause significant downtime and costs. Selecting the right material requires careful thought and research. Don't rush; reflect on your project's specific needs. Testing different materials before making a final choice can be beneficial.

Factors Influencing the Selection of the Right Bearing Material

Assessing Load Capacity and Performance Requirements

When selecting a 25mm pillow block bearing, assessing load capacity is critical. Each application demands different weight and performance levels. Understand the total weight the bearing will support. Sometimes, the actual load can exceed estimates due to dynamic forces. This is where accurate calculations become essential. Overlooking these factors could lead to premature failure or inefficiency.

Performance requirements further complicate the selection process. Different environments can impact bearing performance. For instance, high speeds may generate more heat. Insufficient lubrication can also reduce lifespan. It's important to evaluate operational conditions thoroughly. Consider factoring in temperature changes and vibration levels. Small mistakes during this phase can have large consequences later on.

Many users overlook these elements. They may choose based solely on cost. However, a cheap alternative might not hold up under pressure. Each project has unique demands. Take the time to assess all variables. This reflection will help in making more informed decisions. Ultimately, understanding both load capacity and performance is fundamental for optimal bearing selection.

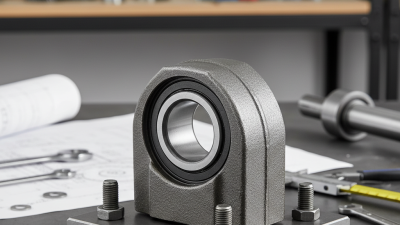

Installation and Maintenance Tips for Optimal Bearing Performance

Proper installation and maintenance of a 25mm pillow block bearing are crucial for ensuring its performance. The right installation techniques can significantly affect the bearing's lifespan. According to industry data, improper installation can reduce bearing life by over 50%. It is essential to ensure the shaft is clean and free of contaminants. Use precision alignment tools to prevent misalignment. Misalignment leads to uneven wear and can cause failure.

Regular maintenance is just as important as installation. Lubrication is key for minimizing friction. A study shows that 30% of bearing failures result from inadequate lubrication. It's advisable to check the grease levels frequently. If the bearing runs hotter than normal, inspect it for foreign particles or damage. Be mindful: neglecting these checks can lead to costly downtime.

Using vibration analysis tools can help detect issues early. Faulty bearings often emit specific vibration patterns. Monitoring these can prevent catastrophic failure. Even minor adjustments can extend the service life of a bearing. However, many overlook these maintenance steps, which can result in unexpected failures.

Related Posts

-

What You Need to Know About 25mm Pillow Block Bearing

-

2025 How to Choose the Right 25mm Pillow Block Bearing for Your Project

-

How to Choose the Right 25mm Pillow Block Bearing for Your Project?

-

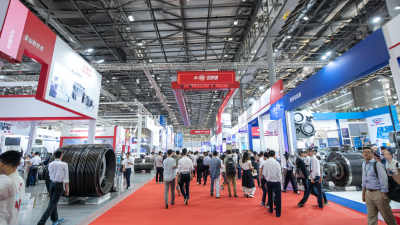

Exploring Split Pillow Block Bearings at the 138th Canton Fair 2025: Industry Insights and Trends

-

How to Find the Best Pillow Block Bearings Near Me for Optimal Performance and Durability

-

Top 10 Pillow Block Bearings Near Me for Optimal Performance and Value