2025 How to Choose the Right 25mm Pillow Block Bearing for Your Project

When embarking on a mechanical project, selecting the appropriate components is crucial for ensuring optimal performance and reliability. Among the essential components, the 25mm Pillow Block Bearing plays a pivotal role in facilitating smooth rotational movement within various machinery setups. Understanding how to choose the right bearing for your specific application can enhance functionality, reduce maintenance needs, and prolong the lifespan of your equipment.

This article will guide you through the key factors to consider when selecting a 25mm Pillow Block Bearing. From load capacity and material selection to housing design and installation methods, these attributes collectively determine how well the bearing will perform under different operational conditions. Additionally, we will explore the common applications of pillow block bearings and how to assess compatibility with your project's requirements. By the end of this discussion, you will be equipped with the knowledge needed to make an informed choice, ensuring that your project not only meets but exceeds performance expectations.

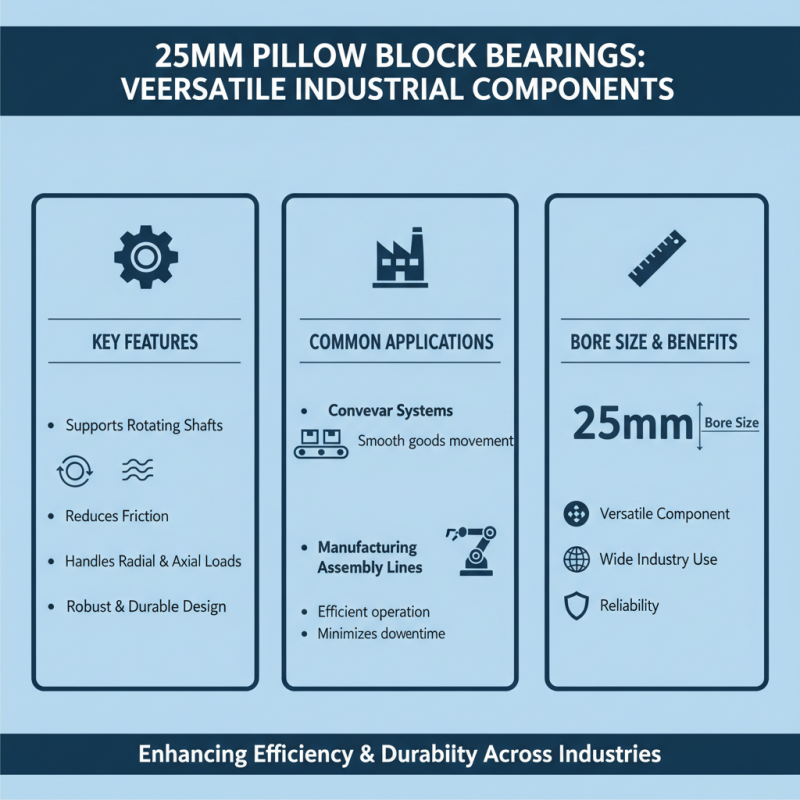

Understanding the Basics of 25mm Pillow Block Bearings for Projects

When embarking on a project that requires the use of bearings, understanding the basics of 25mm pillow block bearings is critical to ensuring that your application runs smoothly and efficiently. These bearings are designed to support rotating shafts while allowing easy installation and maintenance. They feature an outer housing that encapsulates the bearing itself, providing stability and alignment during operation. This makes them an ideal choice for a variety of applications, including conveyor systems, agricultural machinery, and robotics.

When selecting the right 25mm pillow block bearing, it's essential to consider factors such as load capacity, material composition, and environmental conditions. Load capacity refers to the maximum weight the bearing can support without failure, which is a key aspect to match with the project's requirements. Additionally, the material of the bearing, whether it be steel or thermoplastic, can affect its durability and resistance to corrosion or wear. Understanding these aspects will help you choose a bearing that not only fits your project's specifications but also enhances its overall performance and longevity.

Key Specifications to Consider When Selecting Pillow Block Bearings

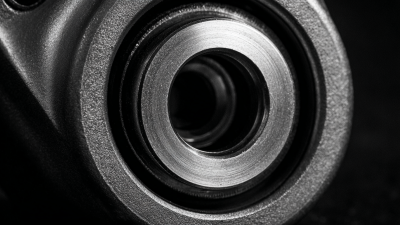

When selecting a 25mm pillow block bearing for your project, there are several key specifications to consider that will significantly impact performance and longevity. First, assess the load capacity of the bearing, which should match the demands of your application. Consider both static and dynamic load ratings to ensure that the bearing can handle the required forces without failure. Additionally, take into account the nature of the loads—whether they are radial, axial, or a combination of both—as this will influence your choice.

Another critical specification is the material and bearing type. Pillow block bearings can be made from various materials, including steel, stainless steel, or plastic, each offering distinct benefits in terms of strength, corrosion resistance, and weight. Furthermore, the type of lubrication system—whether it’s sealed, open, or grease-filled—affects the bearing's maintenance needs and operational lifespan. Finally, evaluating the environmental conditions, such as temperature, humidity, and exposure to contaminants, will guide you in choosing a bearing that can withstand the operational environment while ensuring reliability and efficiency.

2025 How to Choose the Right 25mm Pillow Block Bearing for Your Project - Key Specifications to Consider When Selecting Pillow Block Bearings

| Specification | Details |

|---|---|

| Bore Diameter | 25mm |

| Material | Steel, Cast Iron, or Polymer |

| Load Capacity | up to 3000N |

| Temperature Range | -20°C to +100°C |

| Seal Type | Contact or Non-contact Seals |

| Lubrication | Grease or Oil |

| Mounting Type | Base Mounting, Flanged Mounting |

| Housing Type | Solid or Split Housing |

Comparing Material Options for Enhanced Bearing Performance

When selecting a 25mm pillow block bearing for your project, the choice of material plays a crucial role in determining the performance and longevity of the bearing. Common materials used in the manufacturing of bearing housings include cast iron, aluminum, and thermoplastic. Cast iron offers excellent durability and vibration dampening properties, making it ideal for heavy-duty applications where robustness is paramount. Aluminum, while lightweight and resistant to corrosion, may not provide the same load-bearing capabilities as cast iron but can be advantageous in environments where weight reduction is essential.

Thermoplastic materials, on the other hand, are gaining popularity for their resistance to chemicals and lower friction properties. These materials can enhance the performance of pillow block bearings in applications where exposure to harsh environments or frequent cleaning is necessary. Additionally, thermoplastics allow for quieter operation and can lead to reduced energy consumption in machinery. Evaluating the specific conditions of your project—such as load requirements, environmental factors, and maintenance needs—will help guide you in selecting the most suitable material for optimal bearing performance.

Analyzing Load Capacity and Speed Ratings in Pillow Block Bearings

When selecting a 25mm pillow block bearing for your project, understanding

load capacity and

speed ratings is pivotal.

Load capacity determines how much weight the bearing can support before failure occurs, making it essential to

calculate the expected loads in your application. Overloading can lead to premature wear or complete failure,

so it's crucial to choose a bearing that exceeds your application's demands, considering both dynamic and static

load ratings.

Speed ratings also play a significant role in bearing selection. Each bearing has a maximum rotational speed,

described as the limiting speed of operation. Exceeding this rate can result in increased friction, overheating,

and ultimately, bearing damage. It's important to account for the operational environment and the speeds your

machinery will reach, ensuring you select a bearing designed to handle these conditions effectively.

Tip: Before finalizing your choice, consult detailed specifications

and compare various options. This ensures you have the right balance of load capacity and speed rating tailored

to your unique project requirements. Additionally, consider environmental factors such as temperature and

lubrication, as these can significantly impact performance and longevity.

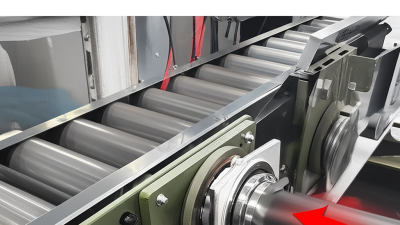

Common Applications and Use Cases for 25mm Pillow Block Bearings

Pillow block bearings with a 25mm bore size are versatile components widely used across various industries due to their ability to support rotating shafts while reducing friction. Common applications of these bearings include conveyor systems, where they facilitate the smooth movement of goods. In manufacturing plants, 25mm pillow block bearings are crucial for driving mechanisms in assembly lines, allowing for efficient operation and minimizing downtime. Their robust design ensures they can handle both radial and axial loads, making them an ideal choice for applications that require reliability and durability.

In addition to their use in conveyor systems, 25mm pillow block bearings are often found in agricultural machinery. They are employed in equipment such as tillers and harvesters, where they help reduce wear and tear on moving parts, ultimately lengthening the lifespan of the machinery. Furthermore, these bearings are also suitable for automotive applications, where they are used in various components, including wheel hubs and other rotating assemblies. Their ability to accommodate misalignment and deliver smooth performance under heavy loads makes them a preferred choice in both industrial and agricultural settings.

Related Posts

-

What You Need to Know About 25mm Pillow Block Bearing

-

Exploring the Benefits of Pillow Block Flange Bearings in Industrial Applications for Enhanced Performance

-

How to Find the Best Pillow Block Bearings Near Me for Optimal Performance and Durability

-

10 Essential Tips for Choosing Small Pillow Block Bearings for Your Projects

-

Top 10 Pillow Block Bearings Near Me for Optimal Performance and Value

-

2025 How to Choose the Right Pillow Block Bearings and Shaft for Your Needs