2025 How to Choose the Right Pillow Block Bearings and Shaft for Your Needs

In the world of industrial machinery, selecting the right Pillow Block Bearings and Shaft is crucial for ensuring optimal performance and longevity. According to Dr. Jane Thornton, a renowned expert in mechanical engineering, "The efficiency and reliability of rotating machinery hinge significantly on the precision and compatibility of bearing systems." Her insights underline the importance of careful consideration when choosing these components, as they directly impact the operational efficiency of various applications.

Selecting suitable Pillow Block Bearings and Shaft requires an understanding of several key factors, including load capacity, material selection, and environmental conditions. With a vast array of options in the market, it's essential for engineers and purchasing managers to analyze their specific needs thoroughly. As technology advances and industries evolve, the demand for high-quality bearings that can withstand rigorous operational conditions has never been higher.

In your quest for the ideal Pillow Block Bearings and Shaft, it is vital to leverage expert guidance and in-depth knowledge about the latest advancements in bearing technology. This article aims to provide insights and practical advice on making informed selections, ensuring that your machinery operates smoothly and efficiently for years to come.

Understanding Pillow Block Bearings: Types and Applications

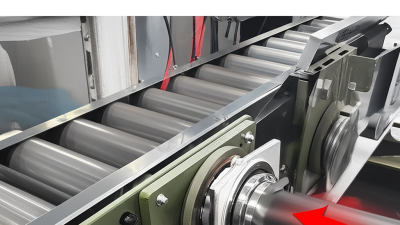

Pillow block bearings are essential components in many industrial applications, providing support for rotating shafts while allowing for smooth and efficient operations. According to a report by the Global Industry Analysts, the global bearing market is projected to reach $130 billion by 2026, with pillow block bearings representing a significant share due to their versatility and ease of installation. These bearings can accommodate both radial and axial loads, making them ideal for a variety of machinery, from conveyors to agricultural equipment.

There are several types of pillow block bearings, each suited for specific applications. For instance, the mounted spherical bearing is particularly effective in applications requiring self-aligning capabilities, effectively compensating for shaft misalignment. This feature is crucial in environments where machinery faces vibration and shock loads. In contrast, pillow block bearings with a solid housing are preferred in heavy-duty applications due to their robustness and capacity to handle higher loads. A survey by the American Bearing Manufacturers Association indicates that over 70% of manufacturing operations utilize some form of pillow block bearing, highlighting their importance in maintaining operational efficiency across diverse sectors.

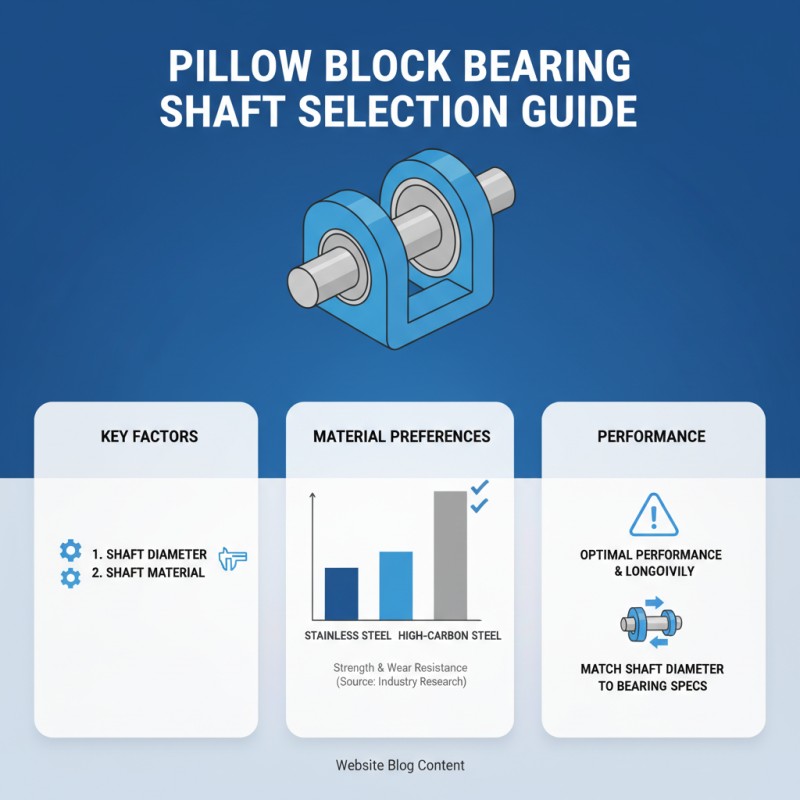

Key Factors in Selecting the Right Shaft for Pillow Block Bearings

When selecting the right shaft for pillow block bearings, several key factors must be considered to ensure optimal performance and longevity. The diameter and material of the shaft are critical, as they directly affect the load capacity and rigidity. According to a report by Industry Research, the global market for shaft materials has seen a significant shift, with stainless steel and high-carbon steel being preferred for their strength and resistance to wear. In applications with high loads or speed, a shaft diameter that aligns with the bearing specifications is essential to prevent failure.

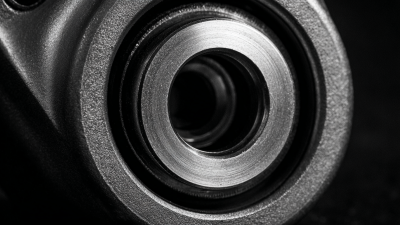

Another important aspect is the surface finish of the shaft. A smoother surface reduces friction and wear, promoting longer bearing life. Data from the American Society of Mechanical Engineers indicates that a surface finish of 16 microinches or better can lead to a 25% increase in bearing lifespan. Additionally, shaft alignment must be taken into account, as misalignment can lead to premature wear and higher operating temperatures. Regular maintenance and the use of precision tools can help maintain optimal alignment, enhancing operational efficiency.

Ultimately, the right combination of shaft specifications tailored to the specific application needs will play a pivotal role in the overall performance and durability of pillow block bearings. Ensuring compatibility between these components is key, based on current industry standards and engineering best practices.

Compatibility: Matching Bearings and Shafts for Optimal Performance

When selecting pillow block bearings and shafts, compatibility is paramount. According to industry reports, up to 70% of bearing failures can be traced back to improper fit and alignment. This highlights the importance of ensuring that the bearing specifications align with the shaft dimensions. Factors such as shaft diameter, tolerance levels, and load ratings must be carefully matched to guarantee optimal performance and longevity.

Tips for achieving the best compatibility include verifying the shaft material and surface finish, as these can affect bearing performance and wear. For instance, a rough shaft surface can lead to premature bearing failure due to increased friction. Additionally, consider the operating environment; higher temperatures and exposure to contaminants may necessitate specific materials or sealing options to prevent degradation.

Moreover, it’s essential to evaluate load conditions, both static and dynamic, to ensure that the selected bearings can handle the operational demands. Industry standards suggest that the calculated loading on bearings should not exceed 75% of their rated capacity to maintain reliability. By prioritizing these compatibility factors, you'll enhance system effectiveness and minimize maintenance costs over time.

2025 How to Choose the Right Pillow Block Bearings and Shaft for Your Needs

| Bearing Type | Shaft Diameter (mm) | Load Rating (N) | Material | Temperature Range (°C) | Applications |

|---|---|---|---|---|---|

| Standard Pillow Block | 30 | 2500 | Cast Iron | -20 to 120 | Food Processing |

| Stainless Steel Pillow Block | 40 | 3000 | Stainless Steel | -40 to 150 | Chemical Industry |

| Heavy-Duty Pillow Block | 50 | 5000 | Ductile Iron | -30 to 200 | Mining |

| Split Pillow Block | 25 | 1800 | Cast Aluminum | -20 to 100 | Textile Industry |

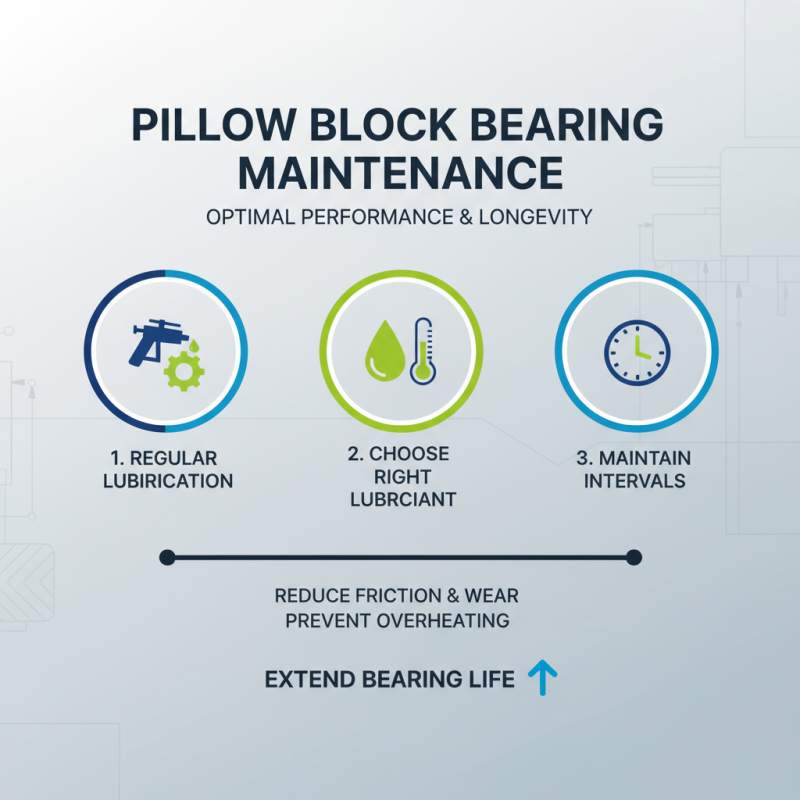

Maintenance Tips for Ensuring Longevity of Pillow Block Bearing Systems

Proper maintenance of pillow block bearing systems is crucial for ensuring their longevity and optimal performance. Regular lubrication is one of the primary maintenance tasks that should not be overlooked. Lubricants reduce friction and wear between moving parts, thus extending the life of the bearings. It's essential to select the right type of lubricant based on the operating conditions and to maintain appropriate intervals for lubrication to prevent overheating and degradation.

In addition to lubrication, regular inspections can help detect issues before they escalate into major problems. Check for signs of wear, contamination, or misalignment in the bearings and shafts. Vibration analysis and temperature monitoring can also provide valuable insights into the system’s health. Ensuring that the housing and surrounding environment are clean and free of debris is another important aspect of maintenance, as contaminants can lead to premature failure. By implementing these practices, you can significantly enhance the durability and reliability of your pillow block bearing systems.

Common Mistakes to Avoid When Choosing Pillow Block Bearings and Shafts

When selecting pillow block bearings and shafts, many individuals and engineers frequently overlook crucial factors that can significantly influence the efficiency and longevity of their machinery. One common mistake is neglecting to consider the load capacity of both the bearing and the shaft. It is essential to understand the operational environment and the specific loads that will be applied during normal use. Underrating these components can lead to premature failure, causing costly downtime and repairs.

Another frequent oversight is failing to account for proper alignment during installation. Misalignment can result in increased wear and tear, leading to vibration and noise that not only reduce the performance of the machinery but can also damage the bearing and shaft over time. Additionally, choosing materials inappropriate for the specific application can further compromise performance. It is crucial to select materials that withstand the operating conditions, including temperature fluctuations and exposure to harsh substances, to ensure the reliability of the assembly in the long term.

Related Posts

-

How to Find the Best Pillow Block Bearings Near Me for Optimal Performance and Durability

-

What You Need to Know About 25mm Pillow Block Bearing

-

Understanding the Role of Small Pillow Block Bearings in Everyday Machinery

-

Exploring the Benefits of Pillow Block Flange Bearings in Industrial Applications for Enhanced Performance

-

10 Essential Tips for Choosing Small Pillow Block Bearings for Your Projects

-

Top 10 Pillow Block Bearings Near Me for Optimal Performance and Value