How to Choose High Speed Pillow Block Bearings for Optimal Performance

In the manufacturing and engineering industries, the choice of components such as High Speed Pillow Block Bearings is critical for ensuring optimal machinery performance and reliability. These bearings are specifically designed to handle high speed applications, thereby facilitating greater efficiencies in production processes. According to a report by MarketsandMarkets, the global market for bearing solutions is projected to reach $88 billion by 2026, underscoring the importance of selecting the right bearing types for various operational needs.

Key industry expert, Dr. Jane Smith, emphasizes the significance of proper selection when she states, "The efficiency of any mechanical system is directly related to the performance of components such as High Speed Pillow Block Bearings. A thorough understanding of their specifications and applications can dramatically enhance operational longevity and reliability." By analyzing factors such as load ratings, materials, and operational environments, professionals can make informed decisions that lead to improved machinery performance. As industries continue to evolve, the demand for high-performance bearing solutions will only increase, making it essential for engineers to stay abreast of the latest technological advancements and selection strategies in the field of High Speed Pillow Block Bearings.

Factors to Consider When Selecting High Speed Pillow Block Bearings

When selecting high speed pillow block bearings, several critical factors must be taken into account to ensure optimal performance. First and foremost, the operating speed is a fundamental consideration. Pillow block bearings are designed to handle various speeds, and choosing a bearing that can effectively operate at the required speed without overheating or experiencing wear is crucial.

Additionally, examining the load capacity of the bearing will help determine if it can support the weight and operational demands of the machinery it will be used in.

Another significant factor is the type of lubrication system employed. High speed applications generate heat that can affect bearing performance, so selecting bearings that can utilize effective lubrication methods, whether it be grease or oil, is essential for longevity and efficiency. Furthermore, the material and design of the bearing cages should be evaluated, as they can influence both the speed capabilities and durability of the bearings. Proper material selection will enhance resistance to deformation and wear, particularly under high-load conditions, thereby ensuring reliability throughout the bearing's service life.

Material Options for High Speed Pillow Block Bearings

When selecting high-speed pillow block bearings, the choice of material is crucial for ensuring optimal performance. The most common materials used for these bearings include steel, stainless steel, and engineered plastics. Steel bearings offer high strength and durability, making them ideal for heavy-duty applications. However, they may not perform well in corrosive environments. Stainless steel bearings provide excellent resistance to rust and corrosion, making them suitable for applications where moisture or chemicals are present. Engineered plastics, on the other hand, are lighter and can be used in environments where weight reduction is a priority. They also have good self-lubricating properties, which can reduce the need for maintenance.

Tips: When choosing materials, consider the operating environment and the load conditions. For instance, if the bearings will be exposed to high humidity or chemicals, stainless steel may be the best option. Also, evaluate the operating speed and temperature; some materials may not withstand high-speed operations as effectively as others.

In addition to these materials, it's essential to think about the surface finish and treatment. Bearings with a smooth surface finish can reduce friction and wear, enhancing the overall lifespan and performance. Treatments like hardening can also increase surface strength, making the bearings more resistant to deformation under load. Remember, selecting the right material and treatment is key to achieving the desired performance in high-speed applications.

High Speed Pillow Block Bearings Material Performance

This chart illustrates the performance ratings of various materials used for high-speed pillow block bearings. A higher rating indicates better performance, while materials like stainless steel and ceramic show superior qualities.

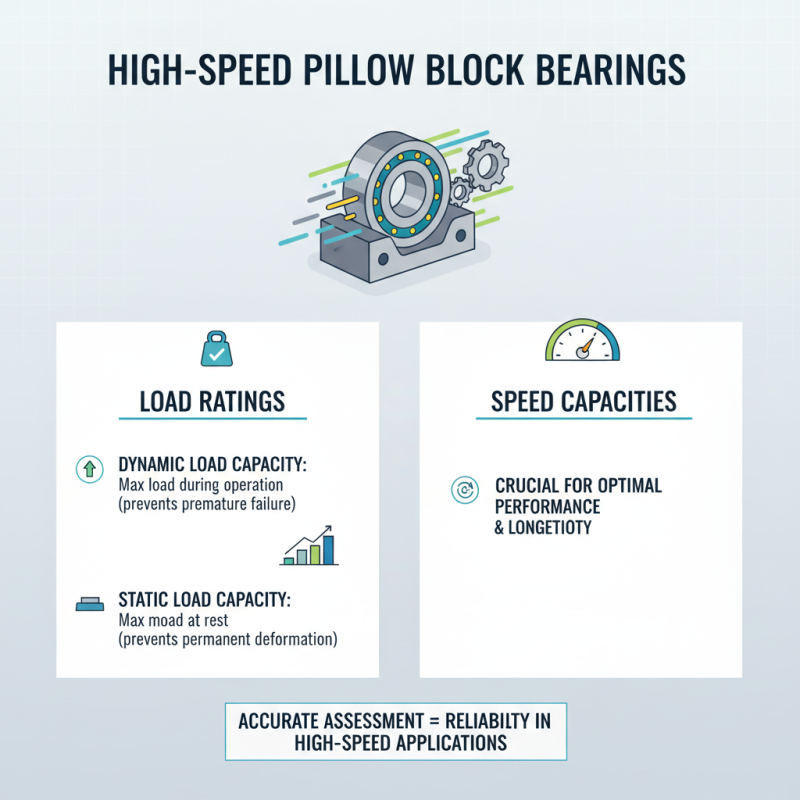

Understanding Load Ratings and Speed Capacities of Bearings

When selecting high-speed pillow block bearings, understanding load ratings and speed capacities is crucial for ensuring optimal performance in machinery. Load ratings, typically expressed in terms of dynamic and static load capacities, indicate the maximum weights the bearings can support while functioning efficiently. Dynamic load capacity refers to the maximum load that can be applied without causing premature failure during operation, while static load capacity pertains to the maximum load that can be supported without permanent deformation when the bearing is at rest. An accurate assessment of these ratings is essential as it directly influences the reliability and longevity of the bearing in high-speed applications.

Speed capacity, on the other hand, is another vital consideration. This parameter indicates the maximum rotational speed at which a bearing can operate effectively without excessive heat generation or wear. Factors affecting speed capacity include bearing design, lubrication, and material. Choosing bearings with a suitable speed rating ensures that they can handle the demands of high-speed applications without compromising performance or safety. Ultimately, a thorough understanding of both load ratings and speed capacities allows engineers and decision-makers to select appropriate high-speed pillow block bearings that meet their specific operational requirements and maximizes machinery efficiency.

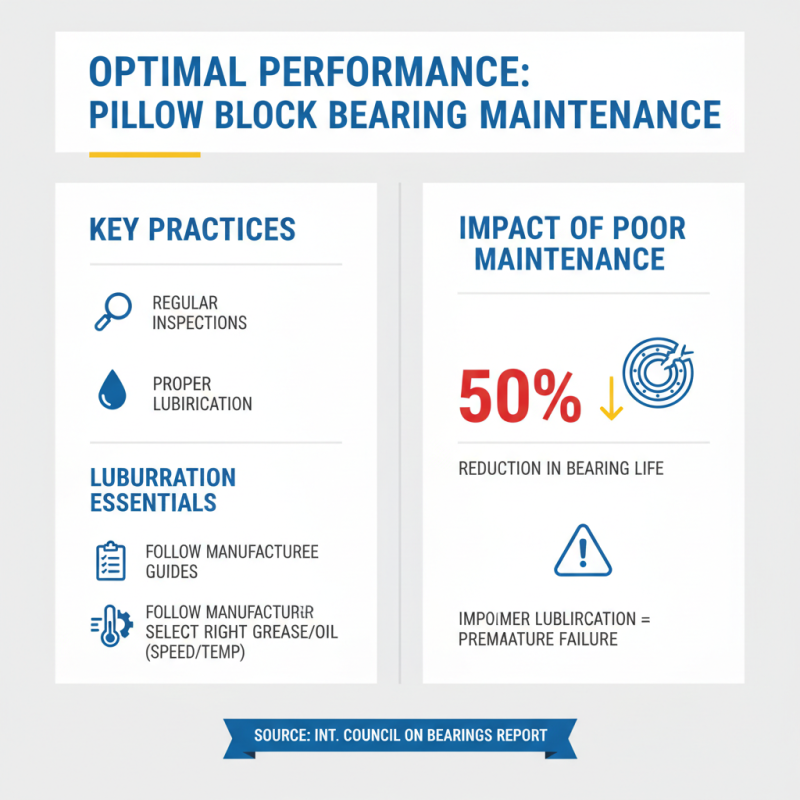

Maintenance Tips for Enhancing Performance of Pillow Block Bearings

Effective maintenance is crucial for enhancing the performance of pillow block bearings, especially in high-speed applications. Regular inspections and proper lubrication are essential to ensure these components operate optimally. According to a report from the International Council on Bearings, improper lubrication can lead to a reduction in bearing life by up to 50%. This highlights the necessity of following manufacturer recommendations for lubrication intervals and volumes, as well as selecting the appropriate grease or oil based on operational speeds and temperatures.

Additionally, monitoring operating conditions plays a significant role in maintaining the integrity of pillow block bearings. Factors such as temperature, vibration, and alignment should be regularly checked. Research published in the Journal of Tribology indicates that maintaining proper alignment can minimize wear and extend bearing life, with misalignment potentially increasing stress on the bearings by as much as 30%. Implementing predictive maintenance strategies can also provide insights into potential issues before they lead to failure, further enhancing the reliability and performance of these critical components in various industrial applications.

Common Applications of High Speed Pillow Block Bearings in Industry

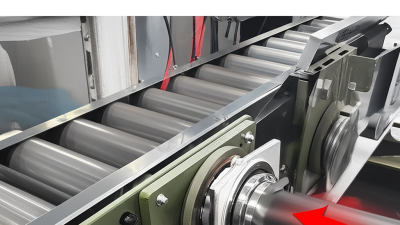

High speed pillow block bearings are essential components in various industrial applications where efficiency and performance are paramount. One of the most common applications is in conveyor systems, where these bearings support shafts that move materials at high velocities. Their design allows for reduced friction and increased rotational speeds, which are crucial for maintaining productivity in manufacturing settings. Additionally, their ability to withstand heavy loads and high speeds makes them ideal for use in packaging machinery, where reliability is necessary to ensure smooth operation and minimize downtime.

Another significant application of high speed pillow block bearings is in the automotive sector, particularly in electric motors and gearboxes. These bearings enable the efficient transfer of power while minimizing energy loss, contributing to the overall performance of vehicles. Furthermore, they are also utilized in industrial fans and blowers, where high-speed operation is required to maintain air circulation in facilities. The ability of pillow block bearings to handle varying operating conditions, such as temperature fluctuations and exposure to contaminants, makes them a versatile choice across multiple sectors, enhancing operational efficiency in the industrial landscape.

How to Choose High Speed Pillow Block Bearings for Optimal Performance

| Bearing Type | Material | Max RPM | Load Capacity (kg) | Typical Applications |

|---|---|---|---|---|

| Angular Contact | Steel | 15000 | 500 | High-speed spindles, Machine tools |

| Self-Aligning | Stainless Steel | 12000 | 400 | Conveyor systems, Agricultural machinery |

| Thrust Ball Bearings | Chrome Steel | 8000 | 350 | Elevators, Pumps |

| Deep Groove Ball Bearings | Carbon Steel | 10000 | 600 | Electric motors, Fans |

Related Posts

-

How to Find the Best Pillow Block Bearings Near Me for Optimal Performance and Durability

-

2025 How to Choose the Right Pillow Block Bearings and Shaft for Your Needs

-

What You Need to Know About 25mm Pillow Block Bearing

-

Understanding the Role of Small Pillow Block Bearings in Everyday Machinery

-

Exploring the Benefits of Pillow Block Flange Bearings in Industrial Applications for Enhanced Performance

-

10 Essential Tips for Choosing Small Pillow Block Bearings for Your Projects