Exploring the Benefits of Pillow Block Flange Bearings in Industrial Applications for Enhanced Performance

In the dynamic landscape of industrial applications, the utilization of Pillow Block Flange Bearings has emerged as a pivotal factor in enhancing equipment performance and operational efficiency. According to a recent report by the Machinery Lubrication Institute, over 75% of industrial machinery failures can be traced back to bearing issues, underscoring the critical role that high-quality bearings play in maintenance and longevity. Pillow Block Flange Bearings are engineered to support rotating shafts, providing stability and alignment that significantly reduce vibration and wear. Additionally, a market analysis conducted by Research and Markets highlights a projected growth of 5.2% in the bearing industry over the next five years, driven by the increasing demand for reliable and high-performance components in manufacturing processes. By exploring the benefits of Pillow Block Flange Bearings, industries can not only optimize their operations but also realize substantial cost savings through reduced downtime and maintenance.

Understanding Pillow Block Flange Bearings: A Comprehensive Overview

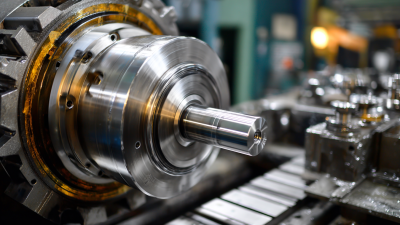

Pillow block flange bearings are critical components in various industrial applications, designed to simplify the mounting process and enhance the performance of rotary machinery. These bearings consist of bearing inserts housed within a flange, which provides a robust support structure and helps accommodate misalignments and vibrations. Their usability across a range of environments—from heavy machinery to conveyor systems—makes them invaluable for optimizing efficiency and reducing wear and tear on equipment.

Recent advancements in bearing technology, such as the introduction of various materials, including stainless steel and thermoplastic options, highlight the increasing versatility of mounted unit bearings. These innovations are tailored to meet the demands of challenging conditions, ensuring superior durability and reliability. By integrating these enhanced pillow block flange bearings, industries can significantly improve the performance and lifespan of their machinery, leading to lower maintenance costs and increased operational uptime. As the market continues to evolve, understanding the comprehensive features and benefits of these bearings becomes essential for businesses aiming to leverage their full potential in modern industrial applications.

Performance Benefits of Pillow Block Flange Bearings in Industrial Applications

This chart illustrates the key performance benefits of using Pillow Block Flange Bearings in various industrial applications, highlighting aspects such as load capacity, vibration reduction, temperature resistance, and lubrication intervals.

Key Advantages of Using Pillow Block Flange Bearings in Industry

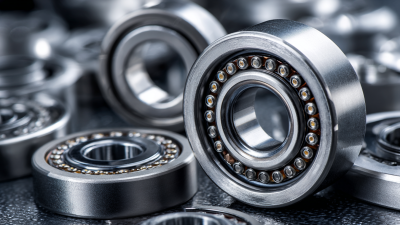

Pillow block flange bearings have become essential in various industrial applications, offering significant advantages that enhance overall equipment performance. One key advantage is their ability to support radial loads, allowing for smoother operation and reduced friction. According to a report by the International Journal of Advanced Manufacturing Technology, the integration of pillow block flange bearings in conveyor systems can improve efficiency by up to 25%. This efficiency gain is attributed to their robust design, which minimizes misalignment issues and prolongs machinery lifespan.

Tips: When selecting pillow block flange bearings, consider the load capacity and operating environment to optimize performance. Regular maintenance checks can further enhance the longevity and reliability of these bearings.

Another notable benefit is their ease of installation, which can significantly reduce downtime during equipment assembly or maintenance. A study from the American Society of Mechanical Engineers highlights that implementing easily mountable bearing solutions can decrease installation times by approximately 30%. This efficiency allows industries to respond more rapidly to production demands and minimizes operational interruptions.

Tips: Always ensure proper alignment during the installation of pillow block bearings to maximize their performance and avoid premature wear.

Common Applications of Pillow Block Flange Bearings in Various Sectors

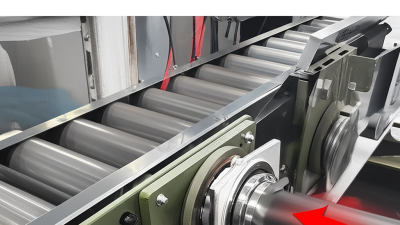

Pillow block flange bearings play a crucial role in various industrial applications due to their robust design and capability to manage heavy loads and high speeds. These bearings are commonly used in equipment such as conveyors, industrial fans, and agricultural machinery, where reliability and efficiency are paramount. Their mounting flexibility allows for easy installation in different orientations, making them suitable for a wide range of operating environments.

Recent advancements in bearing technology, such as re-engineered mounted ball bearing units, have further enhanced the performance of pillow block bearings. These new designs focus on improved durability and reduced maintenance needs, which are critical in sectors like manufacturing and agriculture. As companies strive for greater operational efficiency, the adoption of high-performance pillow block flange bearings can lead to significant improvements in machinery uptime and overall productivity. This makes them an indispensable component across diverse industrial settings.

Comparative Analysis: Pillow Block Flange Bearings vs. Other Bearing Types

Pillow block flange bearings are increasingly recognized for their robust performance in industrial applications. Unlike traditional bearing types such as shaft-mounted bearings or sleeve bearings, pillow block flange bearings provide enhanced stability due to their unique design. They typically feature a built-in housing that supports the bearing, allowing for easier installation and greater load handling capacity. This makes them particularly advantageous in scenarios where vibrations and shock loads are prevalent, such as in conveyor systems and large machinery.

When comparing pillow block flange bearings to other bearing types, one can identify notable differences in maintenance requirements and durability. Pillow blocks tend to require less frequent maintenance owing to their sealing arrangements that keep contamination at bay, thereby extending their operational life. Tips for selecting the right bearing include considering the specific load conditions of your application and ensuring proper alignment during installation to maximize performance.

Moreover, the ongoing advancements in bearing technology correlate with innovations in data handling methods, as seen in recent developments like intelligent data compression techniques. Such progress could influence how we monitor and maintain bearings, paving the way for smarter predictive maintenance strategies in industrial setups. Understanding the benefits of pillow block flange bearings can lead to improved operational efficiencies and reduced downtime in critical applications.

Best Practices for Maintenance and Installation of Pillow Block Flange Bearings

Pillow block flange bearings are essential components in industrial applications, particularly in conveyor systems critical to sectors like mining. Proper maintenance and installation of these bearings can significantly enhance performance and reduce operational costs. One of the key best practices is ensuring that the mounting surface is clean and free from debris before installation. This not only helps in achieving a secure fit but also minimizes vibration and wear, leading to a longer lifespan for the bearings.

Regular inspection and lubrication are also vital. It is important to monitor the condition of the bearings and the surrounding components to catch any signs of wear early. Using the right type of lubricant and applying it at the recommended intervals can prevent overheating and reduce friction, which are common causes of bearing failure. In industrial settings, where downtime can be costly, adhering to these maintenance practices ensures that pillow block flange bearings operate reliably, supporting the efficiency of conveyor systems and ultimately benefiting the overall productivity of the operations.

Related Posts

-

What You Need to Know About 25mm Pillow Block Bearing

-

Unlocking the Benefits of Self Aligning Pillow Block Bearings in Modern Machinery

-

Exploring the Science Behind Bearing Manufacturing: Innovations in Bearing Factory Processes

-

How to Choose the Right Roller Bearing for Optimal Performance and Longevity in Your Machinery

-

How to Choose the Right Stainless Steel Bearing for Your Application

-

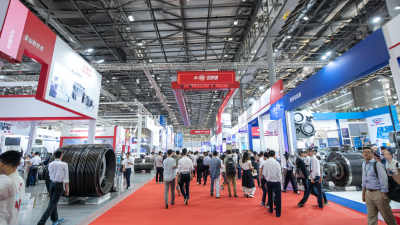

Exploring Split Pillow Block Bearings at the 138th Canton Fair 2025: Industry Insights and Trends