Top Benefits of Cast Steel Block Bearings in 2025 for Industrial Applications

As we move further into 2025, the industrial landscape continues to evolve, driven by advancements in technology and materials science. One of the critical components that play a significant role in enhancing machinery performance is the Cast Steel Block Bearing. These robust bearings are gaining attention for their exceptional strength and durability, making them ideal for a wide range of industrial applications. The demand for reliable bearings is paramount in industries such as manufacturing, construction, and transportation, where operational efficiency and equipment longevity are essential.

The superiority of Cast Steel Block Bearings lies in their ability to withstand heavy loads and extreme operating conditions, minimizing maintenance needs and downtime. By integrating these bearings into their equipment, industries can achieve improved performance metrics and a lower total cost of ownership. As companies increasingly focus on sustainability and environmental impact, the long service life of Cast Steel Block Bearings contributes to reduced waste and resource consumption, aligning with modern industrial goals.

In this article, we will explore the key benefits of adopting Cast Steel Block Bearings in various industrial settings, highlighting their features, advantages, and the transformative impact they are poised to have in 2025 and beyond.

Advantages of Cast Steel Block Bearings for Industrial Use

Cast steel block bearings are gaining prominence in industrial applications due to their robust design and exceptional performance characteristics. One of the primary advantages of these bearings is their impressive load-bearing capacity, making them ideal for heavy machinery and equipment. The strength of cast steel allows these bearings to withstand significant stresses, reducing the risk of deformation and failure even in demanding environments. This durability translates to longer service life and decreased maintenance costs, which are crucial for operations that rely on continuous productivity.

Another significant benefit is the ease of installation and alignment offered by cast steel block bearings. Their design facilitates straightforward mounting, which can lead to reduced labor costs and minimized downtime during installation. Moreover, these bearings can accommodate misalignment, a common issue in industrial settings, thereby further enhancing their reliability. By simplifying maintenance routines and providing stable operational performance, cast steel block bearings contribute to more efficient production processes, allowing industries to focus more on growth and innovation rather than equipment failures.

Durability and Strength of Cast Steel Block Bearings

Cast steel block bearings have gained recognition in industrial applications for their exceptional durability and strength, making them a preferred choice for heavy machinery and demanding environments. A recent industry report indicates that cast steel block bearings can withstand operational loads exceeding 2.5 times that of traditional materials, demonstrating their capability to endure extreme conditions without compromising performance. This remarkable strength minimizes the risk of equipment failure, thereby increasing operational efficiency and reducing downtime, contributing to a more cost-effective manufacturing process.

Moreover, the inherent properties of cast steel provide resistance to various forms of wear and corrosion, a critical factor in industries such as mining and steel manufacturing, where exposure to harsh conditions is common. According to a study by the American Bearing Manufacturers Association (ABMA), the longevity of cast steel block bearings can surpass 50,000 hours under optimal conditions, considerably outlasting standard bearing materials. This durability not only extends the maintenance intervals but also enhances the overall lifecycle of industrial machinery, leading to significant savings in maintenance and replacement costs. Consequently, the integration of cast steel block bearings represents a strategic advantage for industries focused on reliability and sustainability in their operations.

Cost-Effectiveness in Long-Term Applications

Cast steel block bearings are becoming increasingly popular in industrial applications, especially as companies seek cost-effective solutions for long-term operations. The durability and resilience of cast steel make it an ideal choice for environments that experience heavy loads and extreme conditions. Unlike traditional bearings that may require frequent replacement, cast steel block bearings demonstrate significantly extended lifespans. This longevity translates to lower maintenance costs and reduced downtime, ultimately leading to substantial savings for industrial operations.

In addition to their durability, cast steel block bearings offer the advantage of reduced operational expenses over time. Their ability to withstand wear and tear means that industries can minimize the frequency of replacements and repairs. Furthermore, these bearings maintain their performance even under challenging conditions, allowing for consistent output and efficiency. As businesses focus on improving their bottom lines, the cost-effectiveness of cast steel block bearings makes them a strategic investment that enhances productivity while controlling long-term expenses in a competitive market.

Enhanced Performance in High-Load Situations

In the industrial landscape of 2025, cast steel block bearings are gaining recognition for their ability to enhance performance under high-load situations. These bearings are designed to support significantly heavier loads compared to traditional materials, making them essential for sectors such as manufacturing and heavy machinery. The robust structure of cast steel provides superior strength, allowing for better stress distribution and minimizing the risk of failure even in demanding conditions. This advantage not only improves the reliability of equipment but also extends the lifespan of the components, ultimately leading to reduced maintenance costs and downtime.

Moreover, the unique characteristics of cast steel allow for efficient heat dissipation, which is critical during high-load operations. As machinery operates under increased stress, heat build-up can lead to premature wear and tear. Cast steel block bearings mitigate this risk through their ability to withstand elevated temperatures, ensuring consistent operational performance. The enhanced lubrication retention capabilities further facilitate smoother movement, reducing friction and enhancing energy efficiency. This combination of durability and efficiency positions cast steel block bearings as a vital investment for industries aiming to optimize productivity and maintain a competitive edge in the ever-evolving market.

Environmental Benefits and Sustainability Considerations

As industries strive for greater sustainability in 2025, cast steel block bearings emerge as a key component in reducing environmental impacts. Their robust design not only ensures longevity and reliability in various industrial applications but also minimizes the frequency of replacements. By decreasing the overall consumption of materials, these bearings contribute significantly to resource conservation. Their durability and resistance to wear mean that they can operate effectively even in challenging environments, thus, reducing the need for maintenance and associated waste.

Moreover, the manufacture of cast steel block bearings can be optimized to follow sustainable practices. By utilizing recycled steel and implementing energy-efficient production methods, manufacturers can lower their carbon footprint. This shift not only enhances the environmental profile of bearings but also encourages industries to adopt more eco-friendly policies. When viewed holistically, the adoption of cast steel block bearings aligns with corporate sustainability goals, reinforcing a commitment to environmental stewardship while enhancing operational efficiency.

Top Benefits of Cast Steel Block Bearings in 2025 for Industrial Applications

| Benefit | Description | Sustainability Impact | Environmental Consideration |

|---|---|---|---|

| Durability | High resistance to wear and tear, leading to longer product life. | Reduces waste and resource consumption over time. | Less frequent replacements decrease environmental footprint. |

| Low Maintenance | Requires minimal servicing, reducing downtime. | Lower energy consumption due to higher operational efficiency. | Less lubrication and service materials used. |

| High Load Capacity | Designed to handle heavier loads than traditional bearings. | Optimizes resource use in heavy-duty industrial applications. | Minimizes the need for larger equipment, which can be resource-intensive. |

| Corrosion Resistance | Resists rust and corrosion, enhancing reliability in harsh environments. | Extends the useful life of machinery, reducing waste. | Fewer hazardous materials released from corroded machinery. |

| Heat Resistance | Maintains performance under extreme temperatures. | Improves energy efficiency in applications with fluctuating temperatures. | Reduces the environmental impact of energy generation. |

Related Posts

-

Unlocking the Benefits of Self Aligning Pillow Block Bearings in Modern Machinery

-

What is a Roller Bearing and How Does It Improve Machine Efficiency

-

10 Essential Tips for Choosing Small Pillow Block Bearings for Your Projects

-

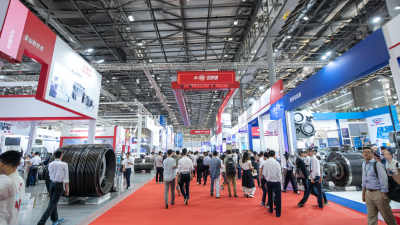

Exploring Split Pillow Block Bearings at the 138th Canton Fair 2025: Industry Insights and Trends

-

The Innovative Future of Bearing Factories and Their Role in Modern Technology

-

2025 How to Choose the Right Pillow Block Bearings and Shaft for Your Needs