Exploring the Advantages of Self Aligning Pillow Block Bearings in Modern Machinery

In today's rapidly evolving industrial landscape, the role of efficient and reliable machinery cannot be overstated. One key component that has gained significant attention is the Self Aligning Pillow Block Bearing. This innovative bearing type not only enhances operational efficiency but also contributes to the longevity of machinery. According to a report by Global Market Insights, the Self Aligning Pillow Block Bearings market is projected to grow at a CAGR of 4.5% over the next five years, driven by the increasing demand across various sectors, including manufacturing, automotive, and aerospace.

Industry expert Dr. Emily Grant, a leading researcher in bearing technology, emphasizes the importance of these bearings in modern applications. She states, "The Self Aligning Pillow Block Bearing plays a critical role in compensating for shaft misalignments, reducing downtime, and ultimately lowering maintenance costs." This quote encapsulates the essence of why embracing this technology is vital for industries seeking to optimize performance and enhance reliability.

As we delve deeper into the advantages of Self Aligning Pillow Block Bearings, it becomes evident that their unique design not only facilitates easier installation and alignment but also ensures smoother operations under dynamic loads. Exploring these benefits will shed light on why these bearings are becoming a preferred choice for engineers and manufacturers alike.

Benefits of Self-Aligning Pillow Block Bearings in Machinery Performance

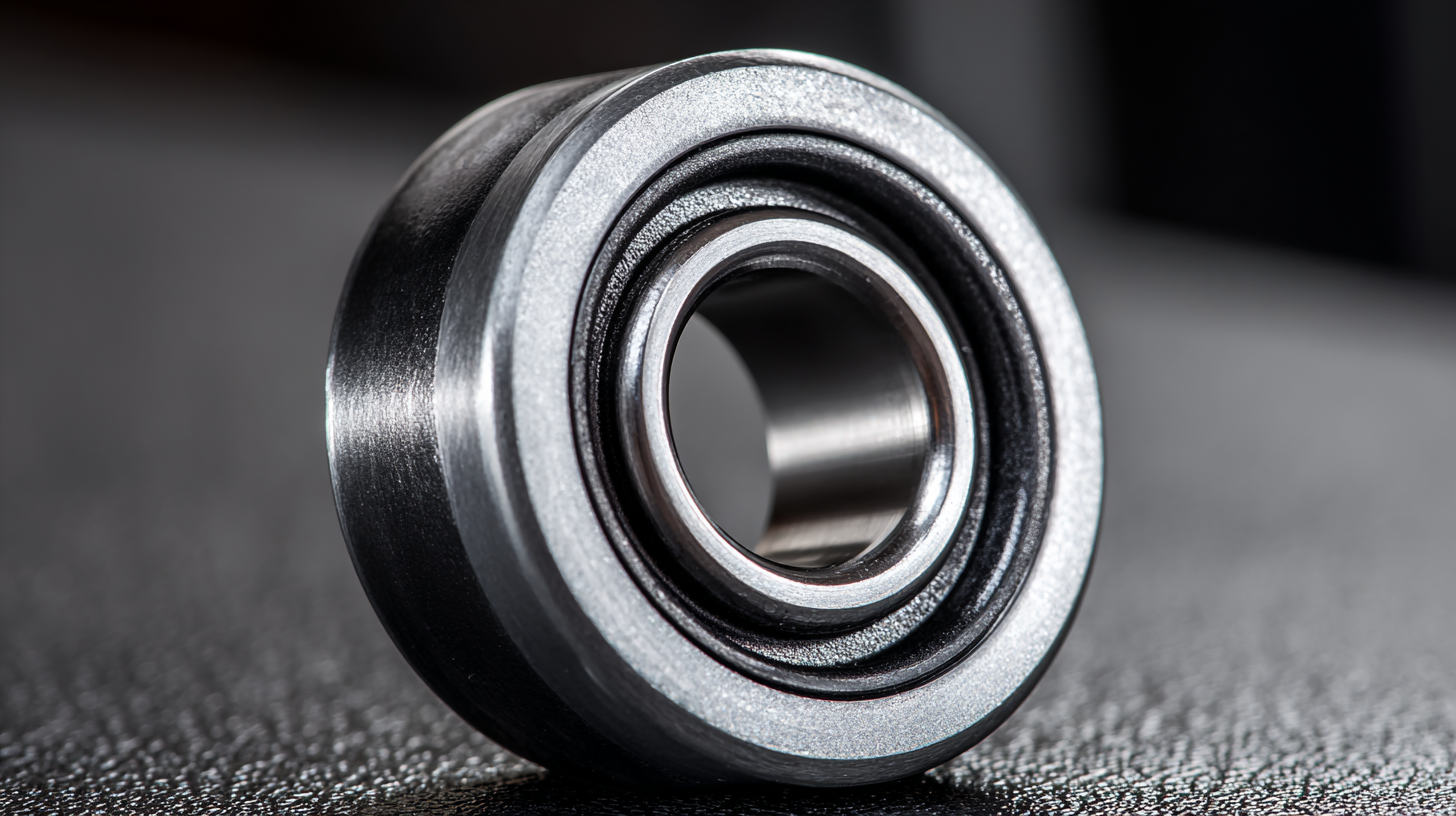

Self-aligning pillow block bearings have become essential components in modern machinery, primarily due to their remarkable ability to enhance performance. One significant advantage of these bearings is their ability to accommodate misalignment. In industrial environments, machinery often experiences vibrations and shifts, leading to misalignment issues. Self-aligning pillow block bearings feature a spherical outer surface that allows them to self-correct, maintaining optimal alignment and thus reducing wear and tear on both the bearings and the shafts they support.

Another benefit of these bearings is their reduced maintenance requirements. Traditional bearing systems often require frequent adjustments and inspections to ensure proper alignment, which can lead to downtime and increased operational costs. However, with self-aligning pillow block bearings, maintenance is streamlined due to their inherent design that minimizes misalignment effects. This leads to increased reliability of machinery, allowing for longer operational periods without interruptions and contributing to overall efficiency improvements in various industrial applications.

Exploring the Advantages of Self Aligning Pillow Block Bearings in Modern Machinery - Benefits of Self-Aligning Pillow Block Bearings in Machinery Performance

| Feature | Benefit | Impact on Machinery Performance |

|---|---|---|

| Self-Alignment | Reduces stress on the shaft | Increases lifespan of components |

| Ease of Installation | Quick and straightforward setup | Minimizes downtime during installation |

| Vibration Damping | Absorbs shocks and vibrations | Improves stability and operation |

| Versatility | Suitable for various applications | Enhances adaptability in machinery |

| Durability | Resistant to wear and fatigue | Reduces maintenance and replacement costs |

| Cost-Effectiveness | Lower overall operational costs | Improves return on investment |

Enhanced Durability and Reduced Maintenance with Self-Aligning Bearings

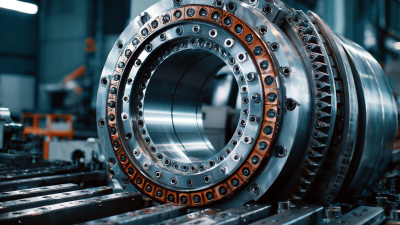

Self-aligning pillow block bearings have gained prominence in modern machinery due to their inherent advantages in durability and reduced maintenance requirements. According to a recent study by the Machinery Reliability Center, the use of self-aligning bearings has been shown to decrease bearing failure rates by up to 50%, significantly extending the lifespan of machinery components. This enhanced durability is attributed to the bearings' ability to accommodate misalignment and temperature variations, which are common challenges in industrial applications.

Moreover, self-aligning bearings contribute to lower maintenance costs, as regular inspections and adjustments are minimized. The National Lubricating Grease Institute reports that machinery equipped with self-aligning pillow block bearings can experience up to a 30% reduction in maintenance downtime. This benefit is crucial for industries aiming for increased operational efficiency, as it allows for smoother production processes and greater profitability. By investing in self-aligning bearings, manufacturers can not only enhance the reliability of their equipment but also optimize their overall maintenance strategies, leading to a more sustainable and productive operation.

The Role of Self-Aligning Pillow Block Bearings in Vibration Reduction

Self-aligning pillow block bearings play a critical role in modern machinery, particularly in vibration reduction, which is vital for maintaining the operational integrity of equipment. According to a recent report by the American Society of Mechanical Engineers, approximately 70% of industrial machinery failures are attributed to excessive vibration. Self-aligning pillow block bearings are specifically designed to accommodate shaft misalignment and ensure continuous contact with the outer raceway, effectively minimizing the vibrations produced during operation. This alignment capability prevents additional wear and tear on machinery, leading to longer service life and reduced maintenance costs.

Moreover, the impact of vibrations on productivity cannot be understated. A study conducted by the International Journal of Mechanical Engineering found that machinery equipped with self-aligning bearings showed a 30% reduction in vibrations compared to traditional fixed bearings. This reduction not only prolongs the lifespan of the machinery but also enhances overall productivity by ensuring smoother operations. Companies adopting self-aligning pillow block bearings can expect significant improvements in equipment reliability and efficiency, ultimately contributing to a more stable manufacturing environment.

Improved Alignment and Load Distribution in Modern Equipment

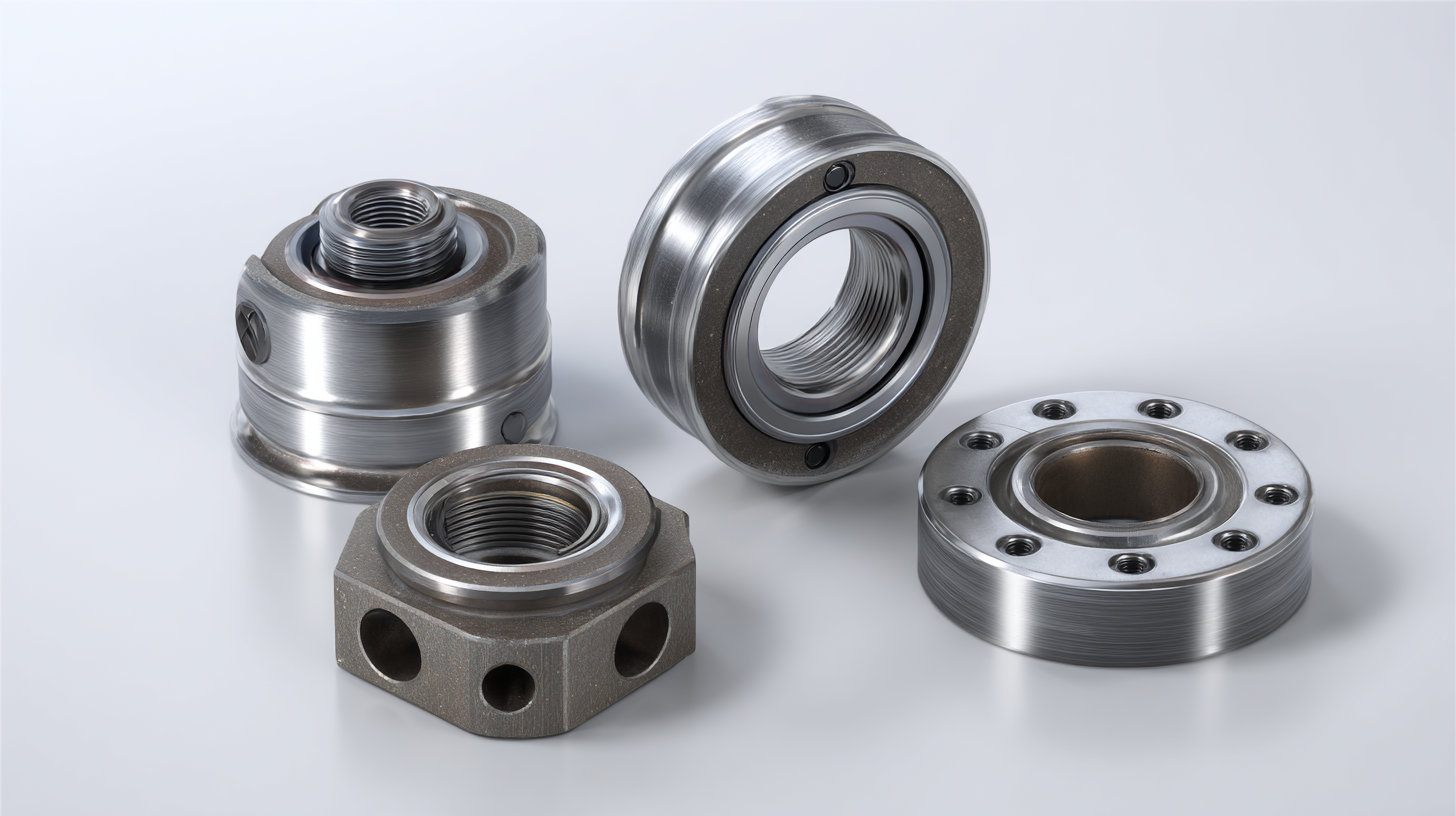

Self-aligning pillow block bearings play a crucial role in enhancing the performance of modern machinery by improving alignment and load distribution. These bearings are designed with unique spherical inner and outer surfaces that allow them to adjust automatically to misalignment caused by shaft deflection or installation errors. This self-adjusting feature minimizes friction and wear, ultimately leading to longer service life and reduced maintenance requirements.

Additionally, the design of self-aligning pillow block bearings contributes to more effective load distribution across the bearing surfaces. When machinery operates, especially under variable loads, the ability to maintain optimal contact between the bearing surfaces is essential. By ensuring consistent alignment, these bearings efficiently distribute loads, which not only protects other components from excessive wear but also enhances the overall stability of equipment. This improved load distribution is particularly beneficial in heavy-duty applications, where the stresses on machinery can be significant.

Applications of Self-Aligning Pillow Block Bearings Across Industries

Self-aligning pillow block bearings are increasingly being adopted across various industries due to their unique design and functionality. These bearings can accommodate misalignments that occur during operation, making them especially valuable in environments where vibration and uneven surfaces are prevalent. In the manufacturing sector, for example, their capability to maintain proper shaft alignment enhances machinery efficiency and reduces downtime, leading to improved productivity.

In agriculture, self-aligning pillow block bearings are crucial for equipment such as conveyors and irrigation systems. Their robustness ensures seamless operation, even in challenging conditions like dust and moisture exposure. Additionally, in the automotive industry, these bearings provide reliable support in machinery that requires precise alignment, thus contributing to the longevity and performance of components.

**Tip:** When selecting self-aligning pillow block bearings, consider the load capacity and environmental conditions to ensure optimal performance. Regular maintenance, including lubrication check-ups, can further extend the lifespan of these bearings and prevent unexpected failures. Always consult with a specialist to match the correct bearing type with your machinery's specific needs.

Applications of Self-Aligning Pillow Block Bearings Across Industries

This chart illustrates the percentage distribution of applications of self-aligning pillow block bearings across various industries. The data shows the versatility and prevalence of these bearings in modern machinery.

Related Posts

-

Understanding the Role of Small Pillow Block Bearings in Everyday Machinery

-

How to Choose the Right Roller Bearing for Optimal Performance and Longevity in Your Machinery

-

Exploring Innovations in Bearing Factory Production: The Future of Machinery Efficiency

-

Exploring Split Pillow Block Bearings at the 138th Canton Fair 2025: Industry Insights and Trends

-

Exploring Innovations in Pillow Block Bearing Pullers at the 138th China Import and Export Fair 2025

-

Mastering Mechanical Maintenance: The Essential Guide to Pillow Block Bearing Pullers for Every Workshop