20mm Pillow Block Bearing Best Applications and Benefits?

The 20mm Pillow Block Bearing plays a critical role in various industrial applications. Its compact size and robust design make it suitable for diverse machinery. According to industry reports, the demand for such bearings is projected to increase by 8% annually. This growth is primarily driven by advancements in automation and machinery efficiency.

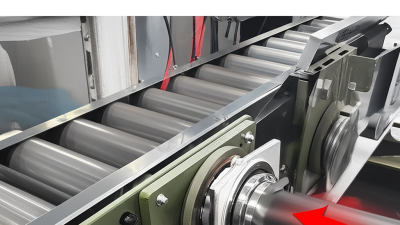

In manufacturing, the 20mm Pillow Block Bearing is essential for ensuring smooth operation. It is often used in conveyor systems, robotics, and agricultural equipment. These bearings are valued for their ability to reduce friction and support heavy loads. However, not all applications realize their potential. Some users overlook proper alignment and installation, leading to premature wear and failure.

Despite the benefits, choosing the right bearing is not always straightforward. The market offers various options, making selection confusing. Some users may opt for lower-cost alternatives, risking performance issues. It is crucial to understand the specifications and intended use of the 20mm Pillow Block Bearing to maximize its benefits. The investment in quality can yield significant returns in reliability and operational efficiency.

20mm Pillow Block Bearing: Definition and Characteristics

The 20mm pillow block bearing is a crucial component in various mechanical systems. It acts as a support for a rotating shaft, providing stability and reducing friction. Typically made of durable materials, these bearings are designed for longevity. Their size is convenient for compact applications, making them popular in both industrial and hobbyist settings.

One key feature of the 20mm pillow block is its easy installation. Aligning the shaft with the bearing takes minimal time. This can improve productivity and reduce downtime. Additionally, the design allows for easy access when maintenance is required.

Tip: Regularly check the alignment of the bearing. Misalignment can lead to excessive wear and tear.

These bearings also offer versatility. You can use them in various applications, from conveyor systems to robotics. However, selecting the right type for your specific use is essential. Using the wrong bearing can affect performance and wear out components faster.

Tip: Understand the load capacity before installation. Overloading can shorten the life of the bearing.

Common Applications of 20mm Pillow Block Bearings

20mm pillow block bearings are versatile components in various machinery. They offer reliable support for rotating shafts. These bearings can handle moderate loads effectively, making them ideal for several applications.

Common applications include conveyor systems. These systems often use pillow block bearings for smooth movement. In agricultural machinery, they help ensure efficient operations. They can also be found in HVAC systems, where they reduce friction. However, improper installation can lead to performance issues. It’s crucial to ensure alignment during setup.

These bearings excel in automation equipment as well. Their ability to maintain stability under dynamic conditions is valuable here. Using them in woodworking machines enhances precision. Regular maintenance is necessary to avoid excessive wear. This requirement might be overlooked in fast-paced environments, which can be problematic. In conclusion, 20mm pillow block bearings serve many practical uses but require attention to detail for optimal performance.

Advantages of Using 20mm Pillow Block Bearings in Machinery

20mm pillow block bearings are crucial in various machinery applications. These bearings excel in providing stability and support for rotating shafts. Industries including agriculture, robotics, and manufacturing utilize them extensively. According to a 2021 industry report, using pillow block bearings can increase machinery efficiency by up to 30%. This is largely due to their ability to handle misalignment and reduce wear.

One major advantage of 20mm pillow block bearings is their ease of installation. Their design allows for quick mounting and dismounting. This can significantly reduce downtime during repairs. However, proper alignment is crucial. Misalignment can lead to premature failure or excess vibration. Always check alignment before installation.

Tip: Regular maintenance is key. Lubricate bearings regularly to avoid wear. Insufficient lubrication can cause overheating and failure, potentially leading to costly repairs. Keep an eye on temperature and noise levels. If either increases, inspect the bearing immediately. Remember, every component has its limits, and it’s essential to operate within them.

Installation and Maintenance Tips for Optimal Performance

Pillow block bearings are vital in many mechanical applications. Their correct installation ensures longevity and optimal performance. Begin by inspecting the housing and shaft for cleanliness. Remove any debris that could hinder alignment.

When mounting the bearing, ensure it's centered on the shaft. Over-tightening can lead to premature wear. Use the proper tools for insertion. It's crucial to maintain a consistent tension to prevent misalignment. Each application may require unique adjustments, so focus on these details for the best results.

Regular maintenance is equally important. Check for lubrication at set intervals. Insufficient lubrication can cause overheating and failure. Listen for unusual noises. These could signal issues that need immediate attention. Always be prepared for unexpected challenges. Adjust your maintenance routine based on the bearing's specific operating environment.

20mm Pillow Block Bearing Best Applications and Benefits

| Application | Benefit | Installation Tips | Maintenance Tips |

|---|---|---|---|

| Agricultural Machinery | High load capacity and durability | Ensure proper alignment before tightening | Regularly grease to prevent wear |

| Conveyor Systems | Smooth operation under continuous load | Check for any misalignment during installation | Inspect for debris and clean regularly |

| Automotive Industries | Reliable performance in harsh environments | Use appropriate torque settings for mounting | Monitor vibrations indicating wear |

| Construction Equipment | Robustness for heavy-duty applications | Install with adequate support housing | Perform periodic lubrication checks |

| Textile Machines | High speed and efficiency | Ensure bearings are secure before operation | Clean and oil regularly to avoid friction |

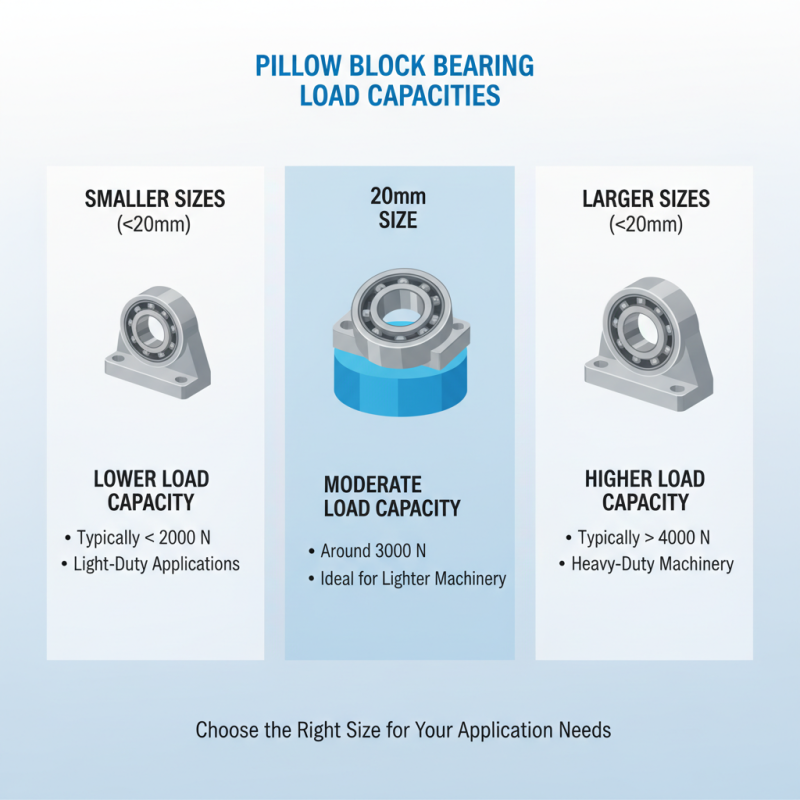

Comparative Analysis of 20mm vs Other Pillow Block Bearings

When comparing 20mm pillow block bearings to other sizes, several factors emerge. The 20mm size is often ideal for applications requiring moderate load capacities. Standard load ratings for 20mm bearings typically reach around 3000 N, making them suitable for machinery with lighter operational demands. Conversely, larger sizes can accommodate higher loads but may not be necessary for less demanding tasks.

Efficiency is another consideration. Smaller pillow block bearings, like the 20mm variant, can minimize friction. This translates into smoother operations and less energy consumption. According to recent industry reports, bearings that offer lower friction can improve equipment lifespan by up to 25%. This is significant for companies looking to reduce maintenance costs.

**Tip:** When selecting a pillow block bearing, consider the specific load requirements of your application. Sometimes, larger bearings may seem advantageous but are not needed.

Remember, not every application will benefit from a 20mm bearing. In heavy-duty scenarios, they may underperform compared to larger alternatives. This brings forth a consideration: balancing cost-efficiency with performance is key. Regular assessments of bearing selection can avoid costly mistakes and improve overall productivity.

**Tip:** Conduct periodic reviews of your equipment performance. It may reveal that the 20mm option performs equally well as a larger bearing in certain setups.

Related Posts

-

How to Find the Best Pillow Block Bearings Near Me for Optimal Performance and Durability

-

Top 10 Pillow Block Bearings Near Me for Optimal Performance and Value

-

2025 Top 5 Harga Pillow Block Bearing: Key Features and Market Insights for Optimal Performance

-

What You Need to Know About 25mm Pillow Block Bearing

-

Exploring the Benefits of Pillow Block Flange Bearings in Industrial Applications for Enhanced Performance

-

10 Essential Tips for Choosing Small Pillow Block Bearings for Your Projects