2025 Top Heavy Duty Pillow Block Bearings for Industrial Applications

In industrial applications, Heavy Duty Pillow Block Bearings play a vital role. Their design caters to high-load capacities and harsh conditions. According to a recent market report, the demand for these bearings is projected to grow by 5% annually over the next five years. This growth reflects industry trends towards increased automation and the need for durable solutions.

Heavy Duty Pillow Block Bearings are essential for machinery performance. They support rotating shafts and reduce friction, ensuring smoother operations. However, selecting the right bearing isn't always straightforward. Factors like load rating, material, and environmental conditions can complicate choices. Many industries still overlook these critical aspects, leading to premature failures and higher costs.

Investing in suitable Heavy Duty Pillow Block Bearings is necessary for reliability. Yet, numerous industry players mistakenly prioritize cost over performance. This can result in equipment downtimes and loss of productivity. Moving forward, a more informed approach is crucial, balancing cost and functionality.

Overview of Heavy Duty Pillow Block Bearings

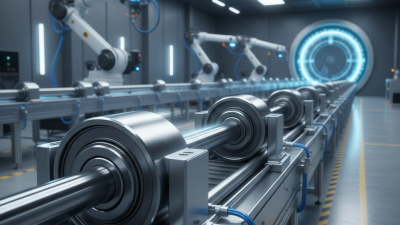

Heavy duty pillow block bearings play a vital role in various industrial applications. These bearings provide support for rotating shafts in demanding environments. The global bearing market is projected to reach $103 billion by 2025, driven by increasing demand in sectors like manufacturing and agriculture. Heavy duty pillow block bearings are designed to handle heavy loads and high speeds, making them essential in heavy machinery, conveyors, and other applications.

When choosing heavy duty pillow block bearings, consider material and design. High-quality materials can enhance longevity and reduce downtime. According to a recent industry report, bearings can account for up to 25% of equipment maintenance costs. Proper selection and maintenance can minimize those expenses. Always pay attention to seals and lubrication methods, as these can significantly impact performance.

Tips: Regularly inspect bearings for wear. Look for signs of overheating or unusual noises. Cleaning the shaft and housing can extend the lifespan of your bearings. Also, ensure that alignment is checked routinely. Misalignment can lead to premature failure, costing you time and money. In some cases, you might need to rethink your bearing choice based on operational requirements.

Key Features of 2025 Top Pillow Block Bearings

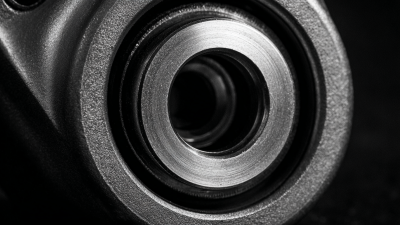

When exploring the key features of top heavy-duty pillow block bearings in 2025, it's essential to understand their design. These bearings are robust. They are crafted for heavy loads. Their materials often resist wear and corrosion. This enhances their longevity and reliability in various industrial applications.

Another notable feature is ease of installation. Many designs prioritize user-friendliness. This reduces setup time and labor costs. Furthermore, some models incorporate adjustable settings. This allows for better alignment and minimal friction. However, not all products meet these expectations. It’s crucial to conduct thorough research before making a decision.

Noise reduction is yet another consideration. Quality pillow block bearings often operate quietly. This can minimize distractions in a workspace. But, flaws in the manufacturing process may lead to excessive noise. Regular inspections are vital to ensure optimal performance.

In conclusion, while key features stand out, continuous evaluating and adapting to specific needs is always necessary.

Applications in Industrial Settings

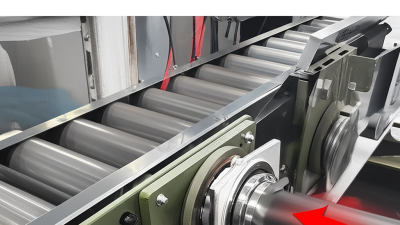

Heavy duty pillow block bearings are vital in various industrial applications. These components bear high loads while ensuring smooth operation. They are essential in manufacturing plants, assembly lines, and facilities with heavy machinery. Often overlooked, their importance cannot be overstated.

In industrial settings, these bearings support rotating shafts and reduce friction. They enhance efficiency in conveyor systems and material handling equipment. However, their installation is sometimes rushed. Skipping necessary alignment can lead to premature wear or failure. Regular inspections are crucial to maintain their performance. Observing wear patterns may provide insights into potential issues.

The environment plays a significant role in the lifespan of pillow block bearings. Exposure to dust, dirt, and moisture can accelerate deterioration. Consequently, proper sealing and lubrication are essential. Some users ignore maintenance schedules due to time constraints. This often results in bigger problems down the line. A proactive approach can prevent costly downtime and repairs.

Comparative Analysis of Leading Brands

The performance of heavy-duty pillow block bearings is crucial in various industrial applications. Analysis of current market data shows a notable increase in demand. In 2023, the global market size for these bearings reached approximately $2 billion. Growth is expected to continue, particularly in sectors like agriculture and mining.

When examining leading brands, efficiency and durability are essential. Many reports indicate that material composition affects performance. For example, bearings made from high-grade alloys demonstrate superior load capacity. However, not all high-grade products deliver consistent results. Some users report premature wear and excessive vibrations.

Adopting advanced technologies presents opportunities for improvement. Innovations in design and materials can enhance lifespan. Yet, readiness to adapt varies among brands. Some seem stuck in older practices, missing the chance to refine their offerings. Industry analysts emphasize the importance of continuous testing and upgrades to meet evolving demands. Regular evaluations could prevent future failures.

2025 Top Heavy Duty Pillow Block Bearings for Industrial Applications - Comparative Analysis of Leading Brands

| Model | Load Capacity (lbs) | Material | Sealing Type | Temperature Range (°F) | Price ($) |

|---|---|---|---|---|---|

| Model A | 5000 | Steel | Double Lip | -20 to 250 | 150 |

| Model B | 7000 | Cast Iron | Labyrinth | -40 to 300 | 200 |

| Model C | 6000 | Stainless Steel | Contact | -30 to 250 | 180 |

| Model D | 8000 | Aluminum | Shielded | -10 to 220 | 220 |

| Model E | 5500 | Plastic | Open | -20 to 150 | 130 |

Future Trends in Pillow Block Bearing Technology

In the evolving world of industrial applications, pillow block bearings are crucial for efficiency. The future trends suggest significant advancements in technology to enhance performance and durability. According to a recent market analysis, the demand for heavy-duty bearings is expected to grow by 30% by 2025, driven by automation and increased machinery use.

Manufacturers are focusing on materials that resist wear and corrosion. For instance, hybrid ceramic and steel combinations are becoming popular. These materials offer better load capacity and longer service life. It’s essential to keep an eye on the latest innovations in lubrication technology as well. Advanced lubricants can reduce friction and increase bearing longevity.

Tip: Regularly check your pillow block bearings for signs of wear. Early detection can save you time and maintenance costs. Another vital point is to ensure proper alignment during installation. Misalignment can lead to premature failure of bearings.

These advancements present both opportunities and challenges. The transition to advanced materials may require new manufacturing processes. Some manufacturers may struggle to adapt quickly. Finally, training for staff on new technologies is critical but often overlooked.

Related Posts

-

How to Find the Best Pillow Block Bearings Near Me for Optimal Performance and Durability

-

2025 How to Choose the Right Pillow Block Bearings and Shaft for Your Needs

-

How to Choose High Speed Pillow Block Bearings for Optimal Performance

-

What You Need to Know About 25mm Pillow Block Bearing

-

Understanding the Role of Small Pillow Block Bearings in Everyday Machinery

-

Exploring the Benefits of Pillow Block Flange Bearings in Industrial Applications for Enhanced Performance